Triisopropanolamine n-heptanoate soap as well as preparation method and application thereof and metal cleaning agent

A technology of triisopropanolamine n-heptanoate soap and metal cleaning agent, which is applied in metal cleaning agent, triisopropanolamine n-heptanoate soap and its preparation method and application field, and can solve the problem that surfactants cannot have antirust at the same time , lubrication, cleaning, alkali resistance and hard water resistance, and achieve good rust resistance, reduced dosage, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of the n-heptanoic acid triisopropanolamine soap of the present application may further comprise the steps:

[0046] (1) Putting n-heptanoic acid of 18% to 25% in mass percentage into the reactor, heating up to 80°C, for subsequent use;

[0047] (2) Slowly drop triisopropanolamine with a mass percentage of 75% to 82% into the reactor, and react at 110 to 130°C for 2 to 4 hours,

[0048] (3) stop heating, naturally cool to room temperature, discharge, be triisopropanolamine n-heptanoate soap.

Embodiment 1

[0051] The embodiment of the present application provides the preparation method of the first triisopropanolamine n-heptanoate soap:

[0052] (1) 21% n-heptanoic acid is dropped into the reactor, and the temperature is raised to 80° C. for subsequent use;

[0053] (2) slowly drop 79% triisopropanolamine into the reactor, and react at 125° C. for 3 hours,

[0054] (3) stop heating, naturally cool to room temperature, discharge, mark as embodiment 1.

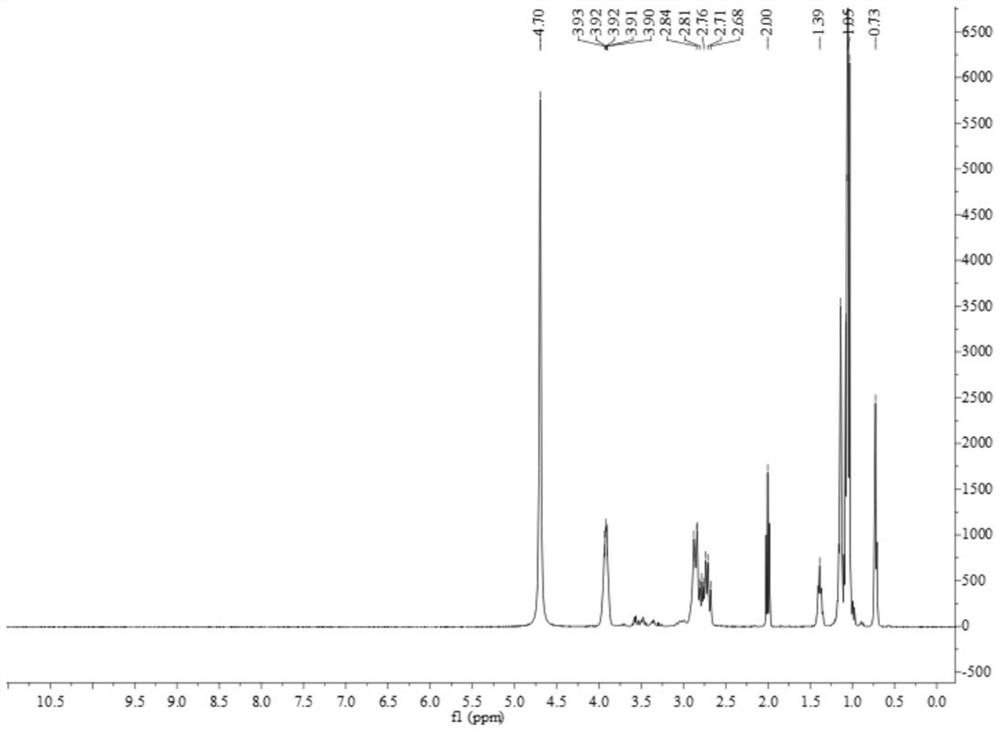

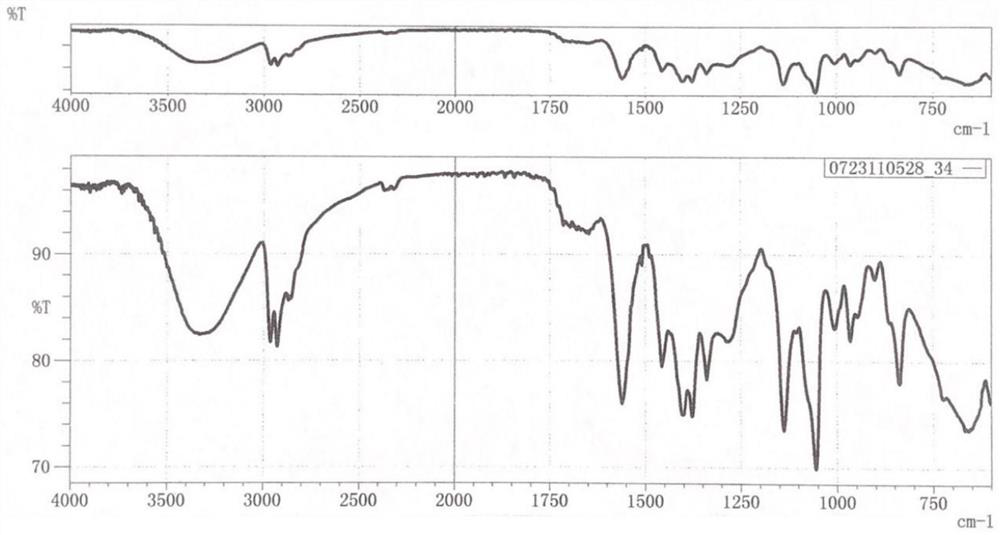

[0055] The N-heptanoic acid triisopropanolamine soap prepared by the embodiment of the present application is detected by infrared spectrogram and proton nuclear magnetic resonance spectrum, and the results are as follows: Figure 1~2 as shown, Figure 1~2 Illustrate that the embodiment of the present application successfully prepares triisopropanolamine n-heptanoate soap.

Embodiment 2

[0057] The embodiment of the present application provides the preparation method of the second triisopropanolamine n-heptanoate soap:

[0058] (1) 18% n-heptanoic acid is dropped into the reactor, and the temperature is raised to 80° C. for subsequent use;

[0059] (2) Slowly drop 82% triisopropanolamine into the reactor, react at 125°C for 3h,

[0060](3) stop heating, naturally cool to room temperature, discharge, mark as embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com