Method for recovering dilute DMF in sucralose crystallization mother liquor wastewater

A crystallization mother liquor, sucralose technology, applied in the direction of organic chemistry, carboxylic acid amide separation/purification, etc., can solve the problems of sewage treatment system load increase, DMF loss, high treatment cost, etc., to save sewage treatment costs, reduce Difficulty, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

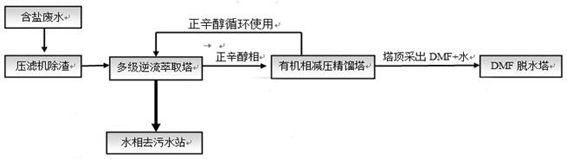

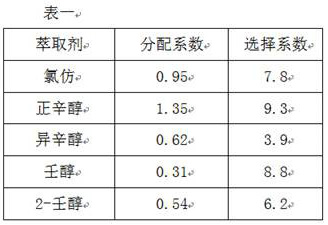

Method used

Image

Examples

Embodiment 1

[0018] (1) Send 24 m³ of waste water (waste water after the crystallization mother liquor is stratified to remove ethyl acetate, 75°C, DMF 3.5%) into a membrane filter press for filtration to remove solid impurities in the waste water;

[0019] (2) Send the filtered wastewater (70°C) into the extraction tower at an amount of 9m³ / h, and add n-octanol to the extraction tower at an amount of 9m³ / h, mix well, let stand for 30min to separate layers, and separate layers The final water phase is directly sent to the sewage station, and the organic phase (7.5% water, 3.5% DMF, 87% n-octanol, and the remaining components are organic impurities) is sent to the middle tank;

[0020] (3) The organic phase in the middle tank is sent to the rectification tower at a volume of 9m³ / h for vacuum distillation. The bottom pressure of the rectification tower is controlled at -0.09MPa, the temperature is 106°C, and the top temperature of the rectification tower is at 92°C, reflux ratio at 0.8:1, 10...

Embodiment 2

[0022] (1) Send 20m³ of waste water (the waste water after the crystallization mother liquor is stratified to remove ethyl acetate, 65°C, DMF 3%) into the membrane filter press for filtration to remove solid impurities in the waste water;

[0023] (2) Send the filtered wastewater (60°C) into the extraction tower at an amount of 8.2m³ / h, and add n-octanol into the extraction tower at an amount of 8.2m³ / h, mix well, and let stand for 25 minutes to separate layers. The stratified water phase is directly sent to the sewage station, and the organic phase (8% water, 3% DMF, 87% n-octanol, and the remaining components are organic impurities) is sent to the middle tank;

[0024] (3) Send the organic phase in the middle tank to the rectification tower at an amount of 8.2m³ / h for vacuum distillation, control the bottom pressure of the rectification tower at -0.07MPa, the temperature at 102°C, and the top temperature of the rectification tower At 88°C, with a reflux ratio of 0.6:1, 10m³ ...

Embodiment 3

[0026] (1) Send 30m³ waste water (waste water after the crystallization mother liquor is stratified to remove ethyl acetate, 70°C, DMF 4%) into a membrane filter press for filtration to remove solid impurities in the waste water;

[0027] (2) Send the filtered waste water (65°C) into the extraction tower at an amount of 10m³ / h, and add n-octanol into the extraction tower at an amount of 10m³ / h, mix well, and let stand for 40 minutes to separate layers. The final water phase is directly sent to the sewage station, and the organic phase (7.8% water, 3.2% DMF, 87% n-octanol, and the remaining components are organic impurities) is sent to the middle tank;

[0028] (3) Send the organic phase in the middle tank to the rectification tower at a rate of 10m³ / h for vacuum distillation, control the bottom pressure of the rectification tower at -0.05MPa, the temperature at 110°C, and the top temperature of the rectification tower at 96°C, reflux ratio at 1:1, 10m³ (including DMF11%) from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com