Antistatic agent for dicyclopentadiene resin and preparation method thereof

A technology of dicyclopentadiene and antistatic agent, applied in the field of antistatic agent, can solve problems such as inactivation of metal carbene curing agent, decline in mechanical properties of products, black products, etc., and achieve long-lasting and effective antistatic properties and compatibility Good performance and color adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

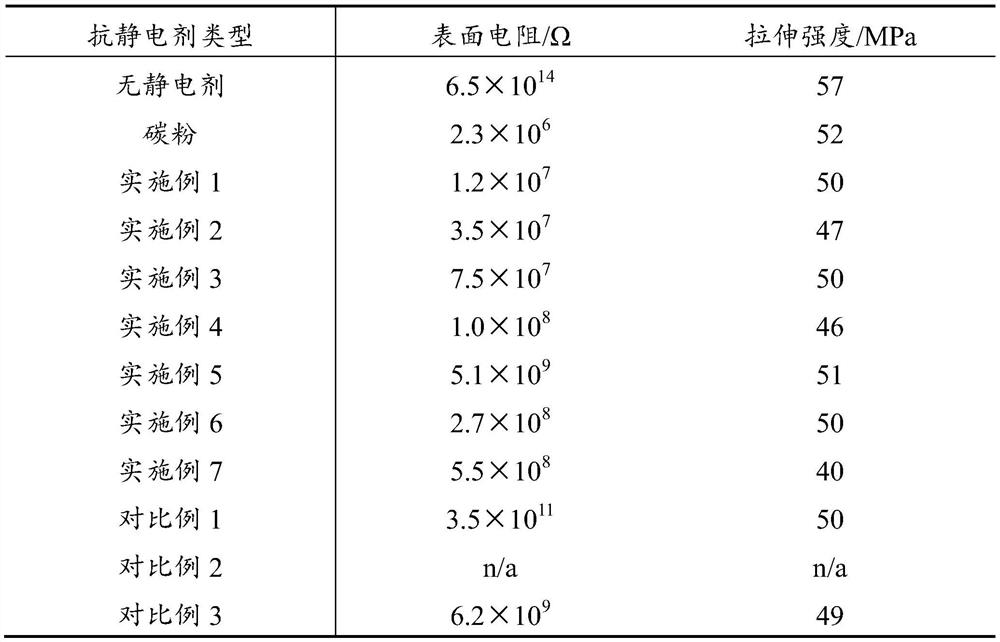

Examples

Embodiment 1

[0020] A kind of embodiment of the antistatic agent that is used for dicyclopentadiene resin of the present invention, the preparation method of antistatic agent described in the present embodiment comprises the steps:

[0021] (1) 45 parts of 5-norbornenyl-2-methylene glycidyl ether and 0.125 parts of lithium carbonate were mixed; then dehydrated at 95°C by nitrogen flow to obtain mixture A;

[0022] (2) Add 0.225 parts of DMC catalyst to the mixture A, feed 55 parts of epibromohydrin, after the addition of epibromohydrin, stir for 2 hours to make the system fully react, then vacuumize and cool to obtain polyether Binary random block copolymers;

[0023] (3) Dissolve the polyether binary random block copolymer obtained in step (2) in ethyl acetate, the mass percentage of the polyether binary random block copolymer is 40%, add N in the solution, N-dimethyl n-octylamine was subjected to quaternization reaction, reacted at 50° C. for 8 hours, and dried in vacuum to obtain the a...

Embodiment 2

[0025] An embodiment of the antistatic agent used for dicyclopentadiene resin according to the present invention, the difference between this embodiment and embodiment 1 is that 5-norbornenyl-2-methylene glycidyl ether is 40 parts, 60 parts of epibromohydrin, 0.11 parts of lithium carbonate, 0.2 parts of DMC, 55 parts of N,N-dimethyl n-octylamine, and the rest of the steps are the same as in Example 1.

Embodiment 3

[0027] An embodiment of the antistatic agent used for dicyclopentadiene resin according to the present invention, the difference between this embodiment and embodiment 1 is that 5-norbornenyl-2-methylene glycidyl ether is 50 parts, 50 parts of epibromohydrin, 0.14 parts of lithium carbonate, 0.25 parts of DMC, 46 parts of N,N-dimethyl n-octylamine, and the rest of the steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com