Sea area natural gas hydrate horizontal well drilling fluid as well as preparation method and application thereof

A technology of hydrate and drilling fluid, applied in the field of drilling fluid, can solve the problems of high demand for lubrication and drag reduction, high build rate and high possibility of hydrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] Based on the same inventive concept, the present invention also provides a method of preparing a sea-to-seafrium natural gas hydrate horizontal well drilling fluid, the preparation method comprising:

[0067] Prepare the components of the drilling fluid;

[0068] The alkalinity modifier is mixed with the fresh water to obtain alkali water;

[0069] The bentonite is mixed with the alkali water to obtain a bentonite freshwater pulp;

[0070] Mix the seawater and the bentonite fresher pulp to obtain a bentonite seawater;

[0071] The low temperature flow conditioning agent, the low temperature filter dosage, the hydrate dynamic inhibitor, the clay stabilizer, and the pole pressure lubricant and the bentonite seawater mixture, obtained Sea natural gas hydrate horizontal well drilling fluid.

[0072] Further, the bentonite and the alkali water are mixed, and the lightwater of the bentonite, including:

[0073] The bentonite was mixed with the alkali water, and the mixture was st...

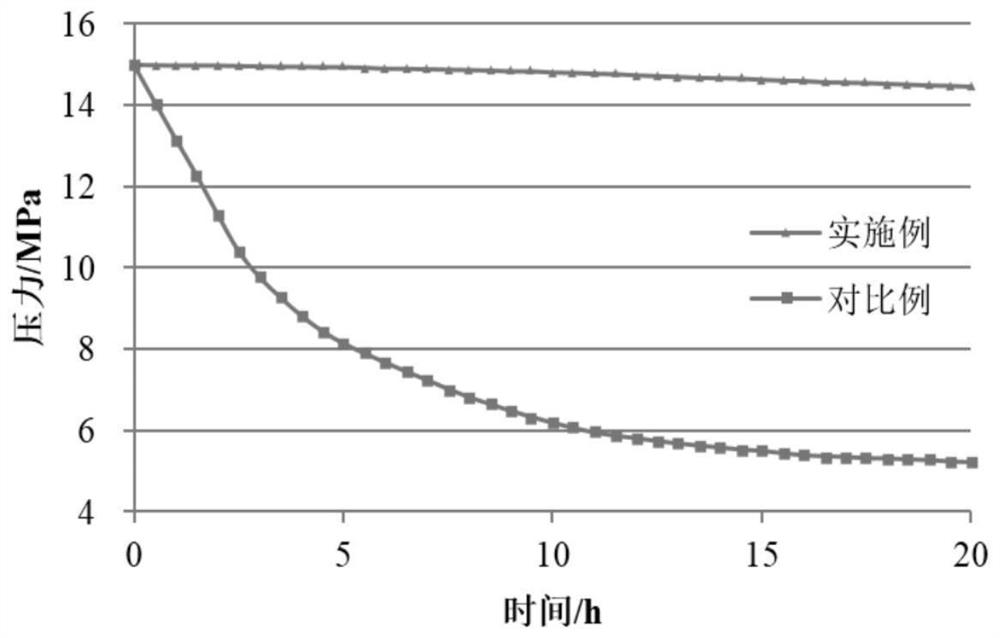

Embodiment 1

[0086] This embodiment provides a sea-to-seawatic water compound horizontal well drilling liquid, including the following components:

[0087] 10g bentonite, 150ml fresh water, 350ml sea water, alkali regulator: 1 g sodium hydroxide, sodium carbonate, 1.5g low temperature flow regulator BDV-110S (specifically: high glutrocarboxymethylcellulose), 5g low temperature filter Lost agent BDF-600S (polyealic cellulose), 5G hydrate inhibitor BDH-100S (polyvinylpyrrolidone), 5G clay stabilizer BDSC-200L (polyether amine), 5G extreme pressure lubricant BDLU-400L (natural Mixtures of vegetable oils, polyol metalloamines, sulfallide cotton seed oil T405).

Embodiment 2

[0089] This embodiment provides a sea-to-seawatic water compound horizontal well drilling liquid, including the following components:

[0090] 15g bentonite, 170ml fresh water, 300ml seawater, alkali regulator: 1.5 g sodium hydroxide, sodium carbonate, 1G low temperature flow regulator BDV-110S (80A51), 7.5g low temperature filter dosage BDF-600S (change Starch), 7.5 g of hydrate inhibitor BDH-100S (polyvinylpyrrolidone and polyvinylhexamide copolymer), 7.5 g of clay stabilizer BDSC-200L (polyether amine), 10G extreme pressure lubricant BDlu-400L ( Natural vegetable oil, polyollamine, mixture of butonlisulfurphosphate T202).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com