Winter roof snow melting system

A technology for melting snow and houses, applied to roofs, roof coverings, and roofs using tiles/slate tiles, etc., can solve problems such as low efficiency and practicability, high energy consumption, damage and deformation of roof panels, etc., to improve snow melting effect, The effect of protecting personal safety and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

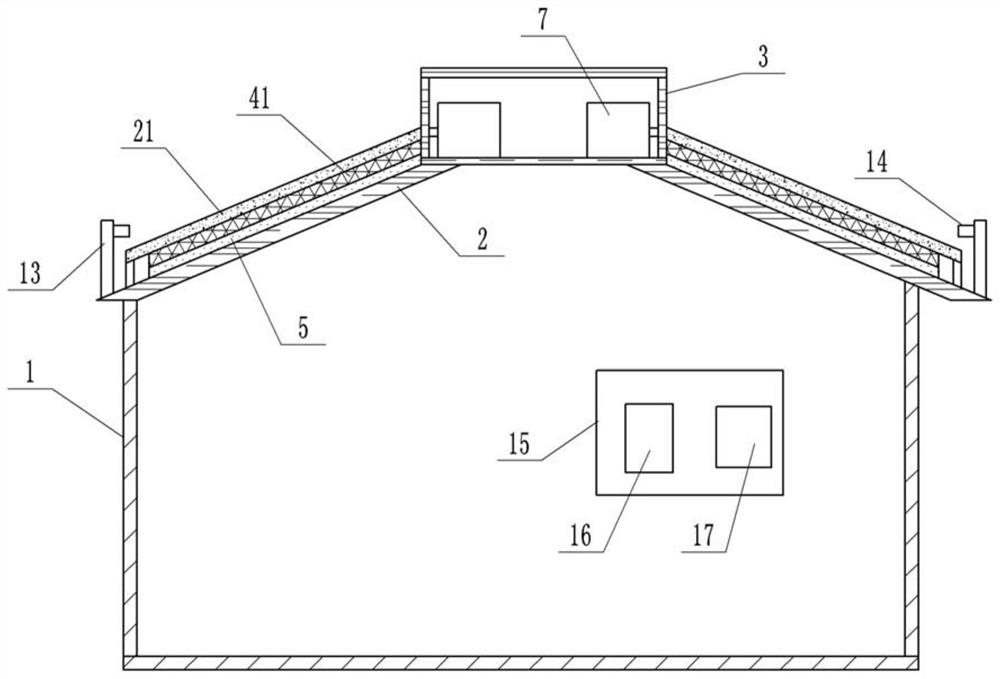

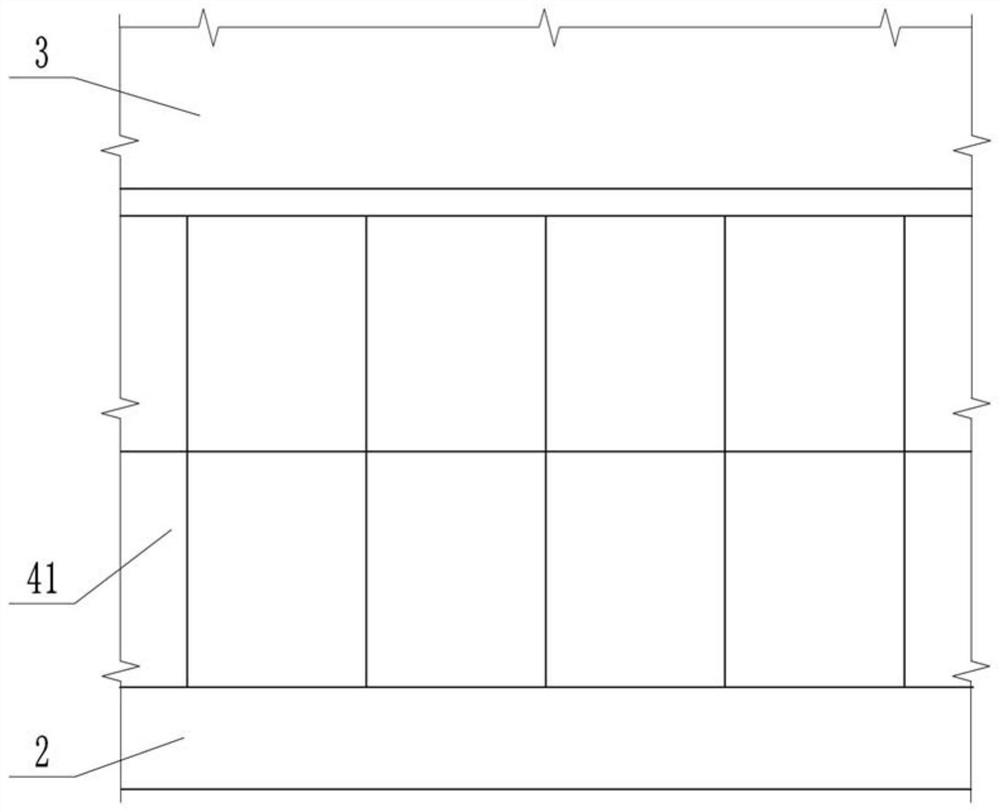

[0045] Such as Figure 1 to Figure 7 As shown, a winter roof snow melting system is installed on a steel structure house 1 and includes a power supply mechanism and a snow melting mechanism 5 . A roof 2 is installed on the steel structure house 1 through screws and purlins, and a hollow ridge 3 is installed on the roof 2 through screws and purlins. A power supply mechanism and a snow melting mechanism 5 are arranged on the roof 2 . A controller 15 is mounted on the wall panel inside the steel structure house 1 by screws, and the controller 15 can be selected from a commonly used PLC controller in the field, such as Siemens S7-200 programmable controller, and the controller 15 is distributed with a display 16 and an operation Taiwan 17.

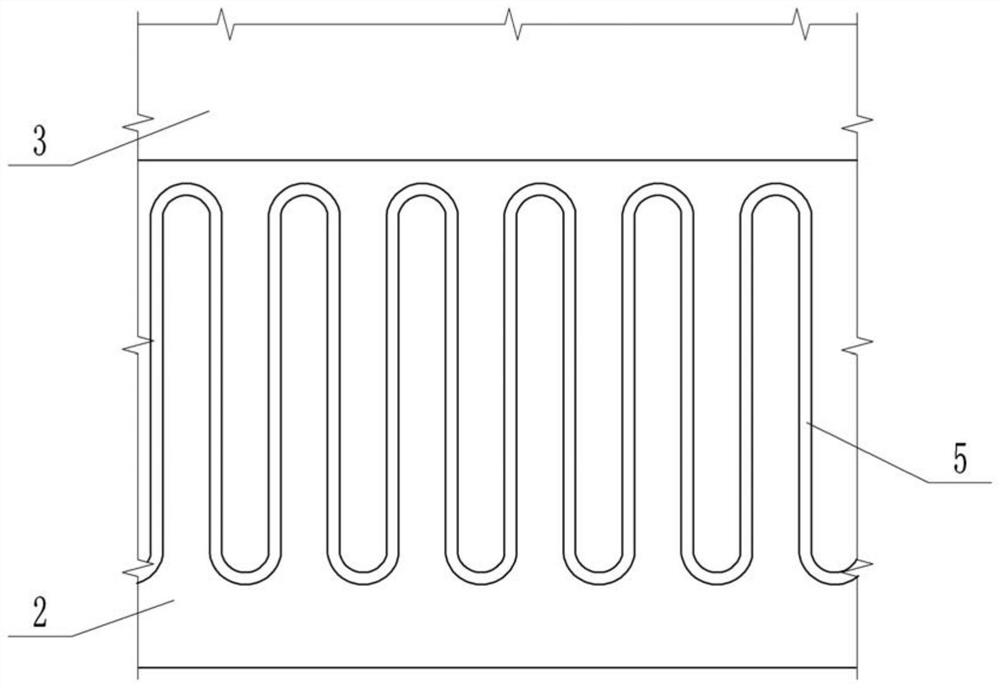

[0046]The snow melting mechanism 5 includes a heating unit. The heating unit is specifically a heating cable or an electric heating cable, which is divided into multiple areas according to the size of the roof 2. The heating cables or electri...

Embodiment 2

[0057] like Figure 8 As shown, a winter roof snow melting system, embodiment 2 is based on embodiment 1, above the baffle plate 6 is provided with a salt water pipe 18, the salt water pipe 18 is installed on the roof 2 through screws and buckles, the salt water pipe 18 Several through holes are opened on the surface abutting against the baffle plate 6 , and the brine pipe 18 is communicated with a water pump, and the water pump is electrically connected with the storage battery of the solar battery unit 4 .

[0058] When it snows in winter, utilize the electric energy stored by the solar cell unit 4 to power the water pump, feed salt water in the salt water pipe 18, and drop the salt water on the baffle plate 6 through the through hole on the salt water pipe 18, and accelerate the speed on the baffle plate 6. The accumulated snow melts and can effectively prevent the melted snow water from freezing again on the baffle plate 6 to absorb heat and cause energy waste, or form ici...

Embodiment 3

[0062] like Figure 9 As shown, a roof snowmelt system in winter, embodiment 3 is based on embodiment 2, and a bristle 19 is glued under the baffle plate 6, and the bristle 19 and the solar panel 41 offset each other. Bristle 19 adopts wear-resistant soft hair, such as high-quality nylon bristle. The bristles 19 can clean and arrange the surface of the solar cell panel 41 along with the movement of the baffle plate 6, and brush away sundries such as dust, catkins, and bird droppings deposited on the surface of the solar cell panel 41, thereby improving the service life and durability of the solar cell panel 41. power generation effect.

[0063] The remaining structure and working principle of embodiment 3 are the same as embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com