Device for preventing and treating cutterhead mud cakes in strong weathered red sandstone stratum and method

A red sandstone, strong weathering technology, applied in chemical instruments and methods, cleaning methods using liquids, cleaning methods and utensils, etc., can solve the problems of prone to collapse accidents, tedious preparation work, small thrust, etc., to avoid the cutter head. Fast speed and super excavation, easy and quick installation and disassembly, and the effect of reducing flushing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

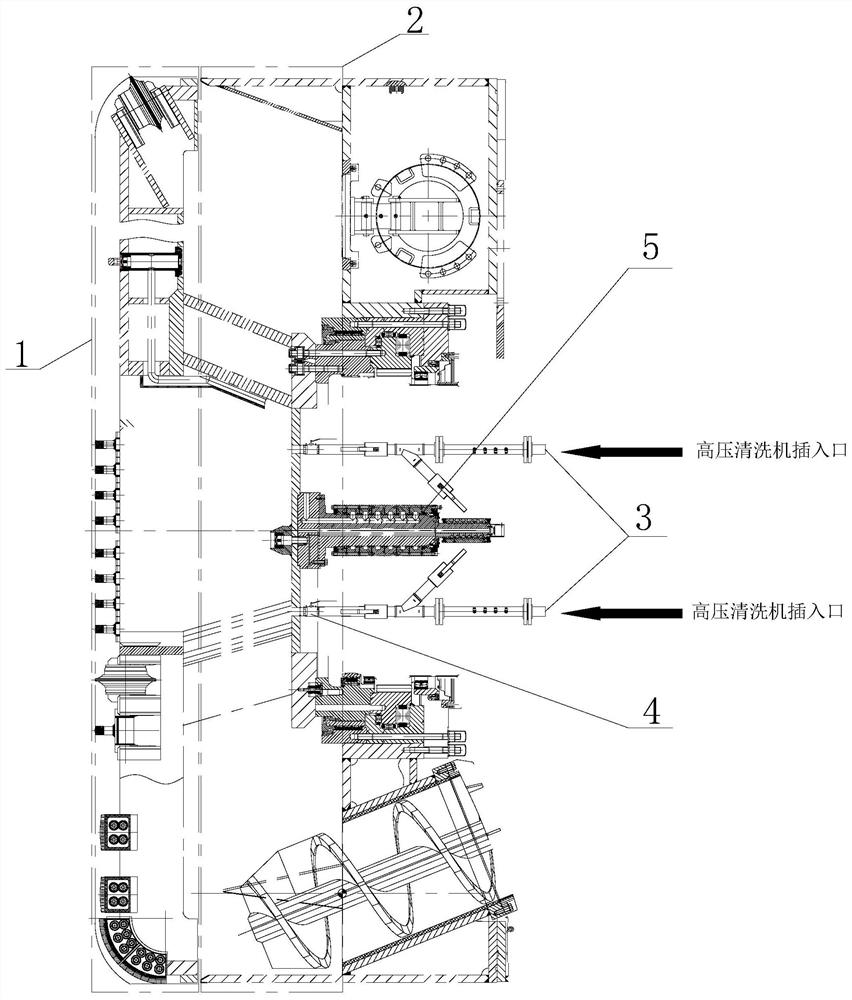

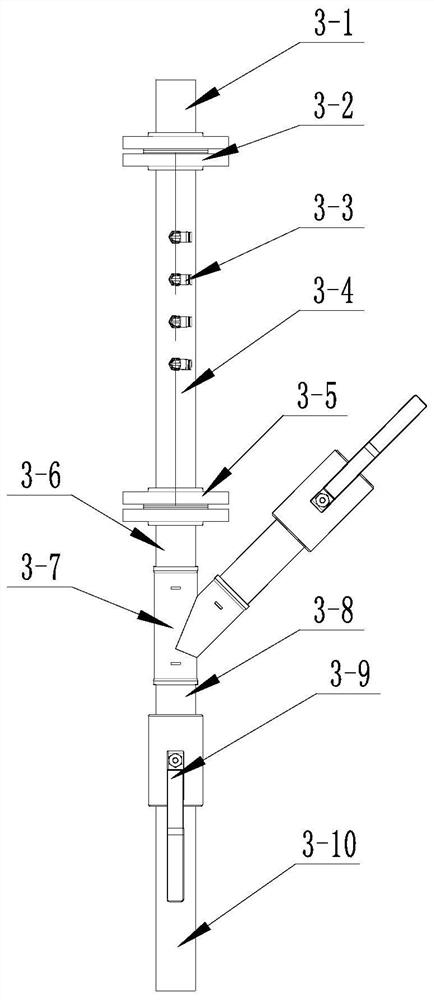

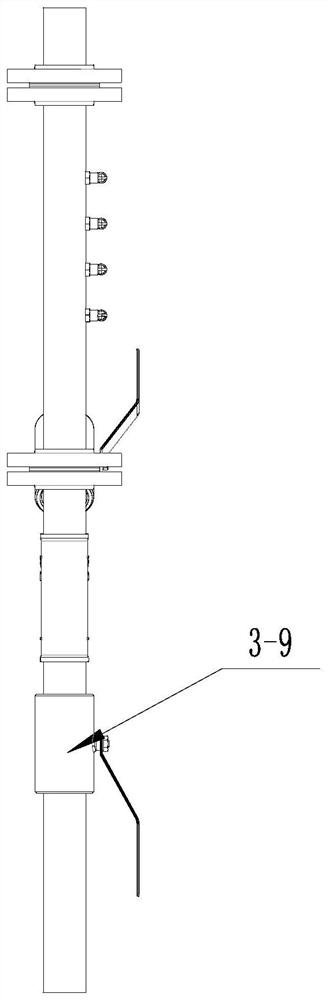

[0036] exist Figure 1~6 Among them, the present invention relates to a device for preventing and treating the mud cake on the cutter head in the strongly weathered red sandstone stratum. There is an earth bin 2 behind the cutter head 1 of the shield machine. According to the size of the cutter head 1, the earth bin 2 One ring of reserved ball valves 4 is installed on the partition, and four reserved ball valves 4 can be installed in each ring. The center of each ring of reserved ball valves 4 is located in the same circumferential surface, and the circumferential surface is coaxial with the center of rotation 5, ensuring The water flow from the gun barrel of the ultra-high pressure cleaning machine can be evenly sprayed on the cutter head 1, and the mud cake on the cutter head can be washed more thoroughly, and the multi-turn reserved ball valve 4 is set to make the washing area larger. The reserved ball valve 4 communicates with an outlet of the drainage and pressure relief ...

Embodiment 2

[0048] In the above-mentioned embodiment 1, in this embodiment, two rings of reserved ball valves 4 are installed on the partition of soil bin 2, and six reserved ball valves 4 can be installed in each ring, and the center of each ring of reserved ball valves 4 is located on the same circumferential surface Inside, and the circumferential surface is coaxial with the center of rotation 5, and the reserved ball valves 4 in adjacent circles are arranged in a misaligned position. All the other components and their connections are identical to those of Embodiment 1, and the processing method is identical to that of Embodiment 1.

Embodiment 3

[0050] In the above-mentioned embodiment 1, in this embodiment, three rings of reserved ball valves 4 are installed on the partition of soil bin 2, and three reserved ball valves 4 can be installed in each ring, and the center of each ring of reserved ball valves 4 is located on the same circumferential surface Inside, and the circumferential surface is coaxial with the center of rotation 5, and the reserved ball valves 4 in adjacent circles are arranged in a misaligned position. All the other components and their connections are identical to those of Embodiment 1, and the processing method is identical to that of Embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap