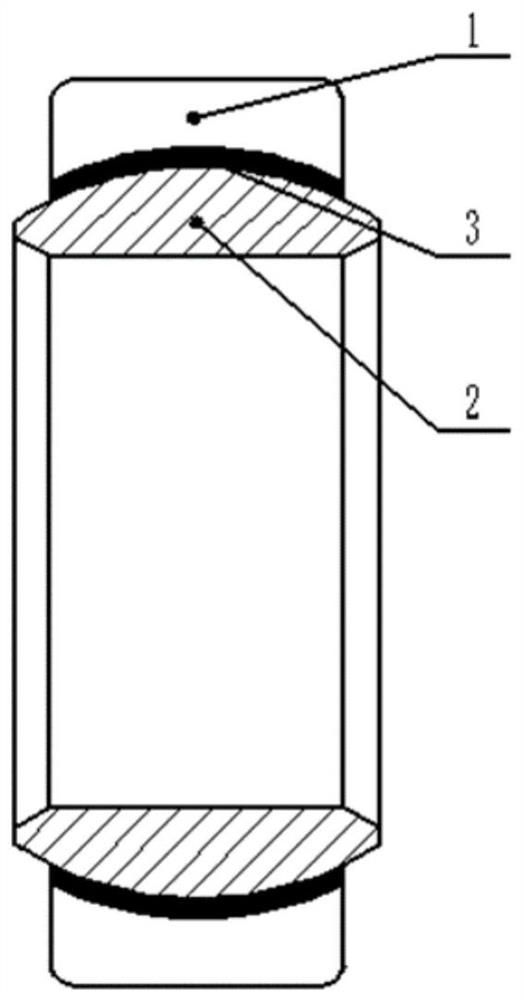

Light-weight self-lubricating wear-resistant joint bearing and preparation method thereof

A joint bearing and self-lubricating technology, which is applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., to achieve the effect of expanding the scope of use, improving service life, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

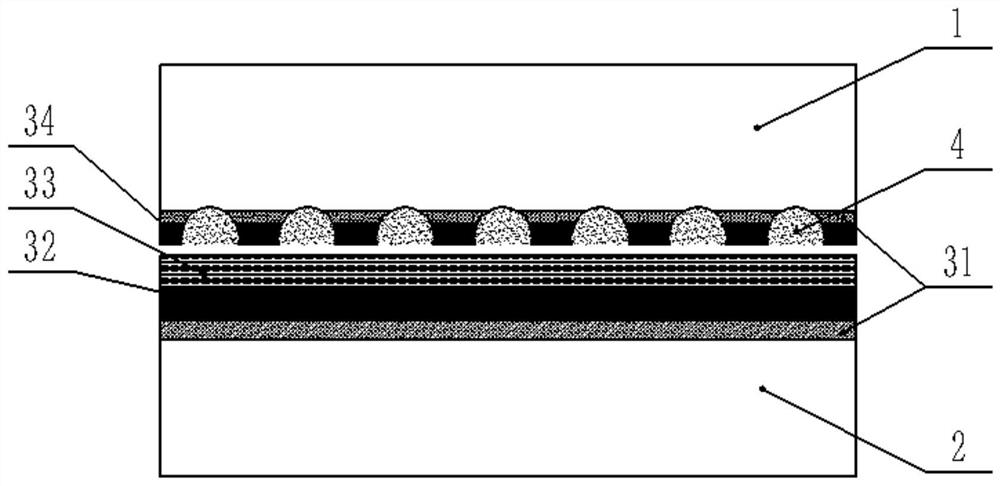

[0052] In step (1), the joint bearing uses TC11 titanium alloy as the base material of the inner ring, and TC4 titanium alloy as the base material of the outer ring, and polishes the surface of the bearing base to ensure that the surface roughness of the base is Ra≤0.05 μm.

[0053] Step (2), ultrasonically clean the inner ring of the joint bearing for 15 minutes to remove burrs and other stains on the surface of the inner ring substrate, put the workpiece in acetone for dehydration treatment, fully dry the surface of the workpiece and put it into the vacuum chamber of the coating machine Prepare the coating in the middle; use the multi-arc ion plating method to deposit TiN coating on the outer spherical substrate of the inner ring, the thickness of the TiN transition layer is 1 μm; then deposit a TiAlN hard coating on the TiN transition layer, the thickness of the TiAlN hard coating is 3 μm ; Deposition of MoS on TiAlN coating by magnetron sputtering 2 Soft coating, MoS 2 Th...

Embodiment 2

[0059] In step (1), the joint bearing uses TC11 titanium alloy as the base material of the inner ring, and TC4 titanium alloy as the base material of the outer ring, and polishes the surface of the bearing base to ensure that the surface roughness of the base is Ra≤0.05 μm.

[0060] Step (2), ultrasonically clean the inner ring of the spherical plain bearing for 20 minutes to remove burrs and other stains on the surface of the inner ring substrate, put the workpiece in acetone for dehydration treatment, fully dry the surface of the workpiece and put it into the vacuum chamber of the coating machine prepare for coating;

[0061] The multi-arc ion plating method is used to deposit TiN coating on the outer spherical substrate of the inner ring, and the thickness of the TiN transition layer is 2 μm; then, a TiAlSiN hard coating is deposited on the TiN transition layer, and the thickness of the TiAlSiN hard coating is 5 μm; Deposition of WS on TiAlSiN coating by sputtering 2 Soft ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com