Pole piece with uniform thickness of tab ceramic coating and preparation method thereof

A technology of ceramic coating with uniform thickness, which is applied in electrode current collector coating, electrode manufacturing, battery electrodes, etc. It can solve the problems of short circuit, easy short circuit in the tab area, lithium precipitation, etc., and achieve simple preparation process and reduce short circuit The effect of lithium precipitation phenomenon, high quality and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

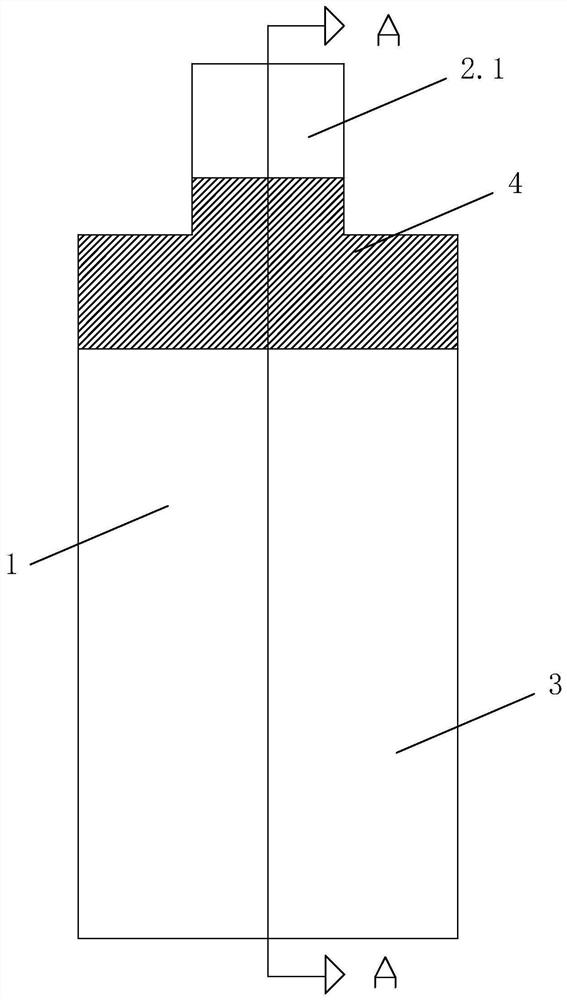

Image

Examples

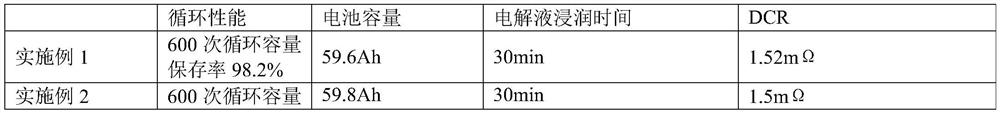

Embodiment 1

[0039] A method for preparing a pole piece with a uniform thickness of the lug ceramic coating, comprising the following preparation steps:

[0040] (1) Coating the active material: apply the active material slurry at a rate of 19.5 mg / cm on one side 2 The coating amount is evenly coated on the surface of the foil; the thickness of the foil is 6 μm, and the active material coating is nickel cobalt lithium manganate or graphite coating.

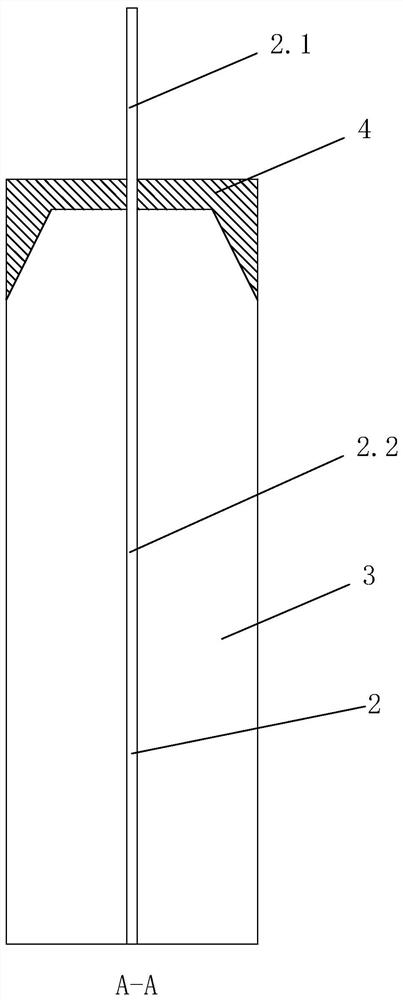

[0041] (2) Coating ceramic coating: while coating the active material, the prepared ceramic slurry coating is coated on the connection area, and the ceramic coating covers the 5mm tab and the 10mm middle area respectively; the middle area ceramic coating and The connection area of the active material coating is a slope connection, and the maximum thickness of the ceramic coating on the slope connection is 1 / 4 of the thickness of the pole piece.

[0042]The preparation steps of the ceramic slurry include: 1) Preparation of ceramic powder sol...

Embodiment 2

[0047] The difference from Example 1 is that a method for preparing a pole piece with a uniform thickness of the lug ceramic coating includes the following preparation steps:

[0048] (1) Coating the active material: apply the active material slurry at a rate of 19.8 mg / cm on one side 2 The coating amount is evenly coated on the surface of the foil; the thickness of the foil is 10 μm, and the active material coating is nickel cobalt lithium manganate or graphite coating.

[0049] (2) Coating ceramic coating: While coating the active material, coat the prepared ceramic slurry coating on the connection area, and the ceramic coating covers the 5mm tab and the 10.5mm middle area respectively; the middle area ceramic coating The connection area with the active material coating is a slope connection, and the maximum thickness of the ceramic coating on the slope connection is 3 / 10 of the thickness of the pole piece.

[0050] The ceramic slurry preparation steps include: 1) ceramic p...

Embodiment 3

[0055] The difference from Example 1 is that a method for preparing a pole piece with a uniform thickness of the lug ceramic coating includes the following preparation steps:

[0056] (1) Coating the active material: apply the active material slurry to 20mg / cm on one side 2 The coating amount is evenly coated on the surface of the foil; the thickness of the foil is 12 μm, and the active material coating is nickel cobalt lithium manganate or graphite coating.

[0057] (2) Coating ceramic coating: While coating the active material, coat the prepared ceramic slurry coating on the connection area, and the ceramic coating covers the 5mm tab and the 11mm middle area respectively; the middle area (2.2) ceramic The connection area between the coating (4) and the active material coating (3) is an inclined connection, and the maximum thickness of the ceramic coating on the inclined connection is 7 / 20 of the thickness of the pole piece.

[0058] The ceramic slurry preparation steps incl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com