Implementation method of single-caliber multi-feed-source multi-beam feed source assembly

An implementation method, multi-beam technology, applied in electrical components, specific array feeding systems, antenna arrays, etc., can solve the problems of small structural envelope, complex cascade, large number of passive components, etc., to reduce the difficulty of processing , Improve radiation efficiency and avoid electromagnetic wave leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

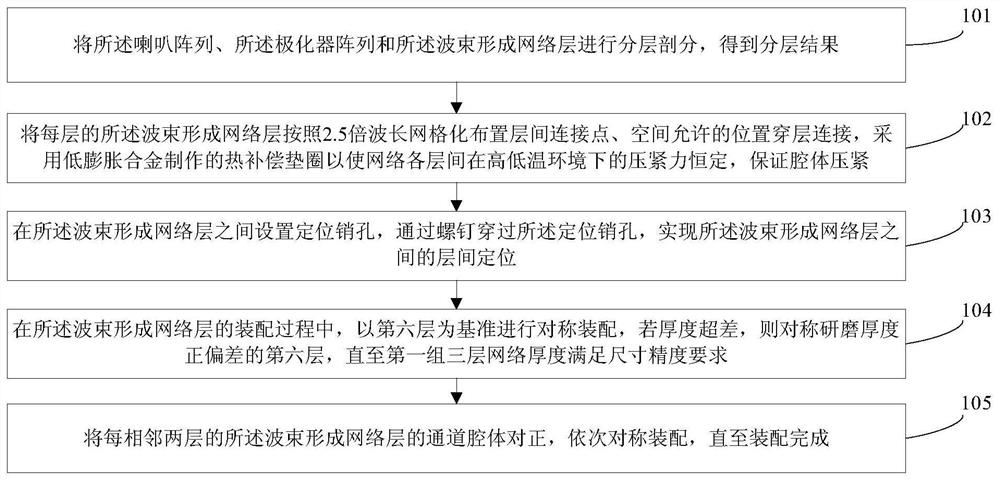

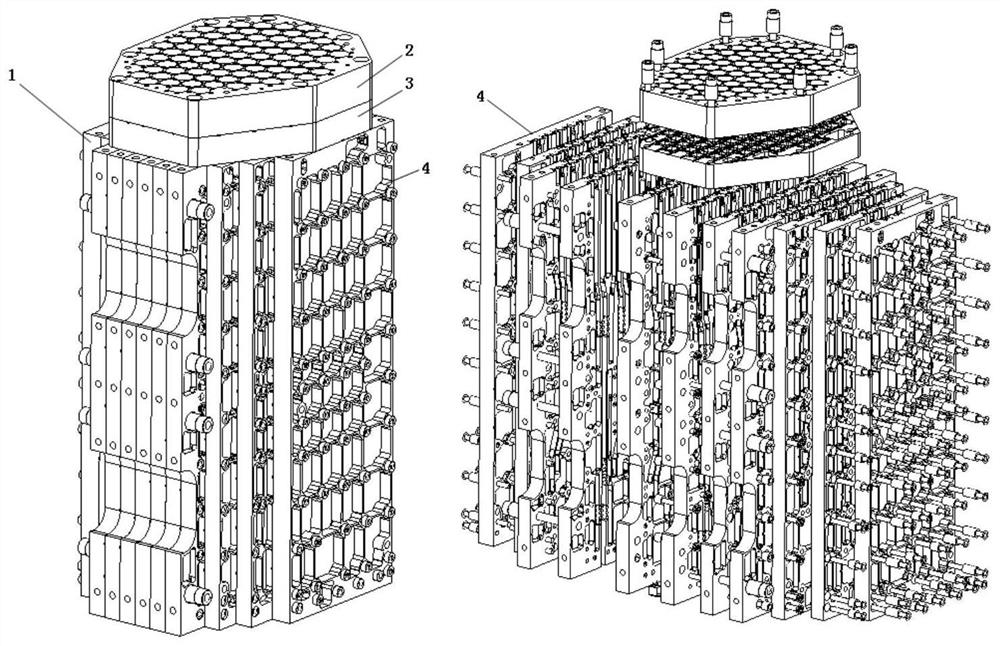

[0046] refer to figure 1 , shows a method for implementing a single-aperture multi-feed multi-beam feed assembly provided by an embodiment of the present invention, as shown in figure 2As shown, the feed assembly may include a multi-feed multi-beam feed array 1, and the multi-feed multi-beam feed array 1 is a hierarchical structure formed by a horn array 2, a polarizer array 3 and a beamforming network layer 4, The beamforming network layer 4 is formed by cascading multiple layers of passive branch line couplers and phase shifters. The methods include:

[0047] Step 101: Layering the horn array, the polarizer array, and the beamforming network layer to obtain a layered result; wherein, the polarizer array is located between the horn array and the beamforming network layer between network layers.

[0048] The feed source component provided by the embodiment of the present invention may be a component working in the Ka frequency band, and the Ka frequency band single-apertur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com