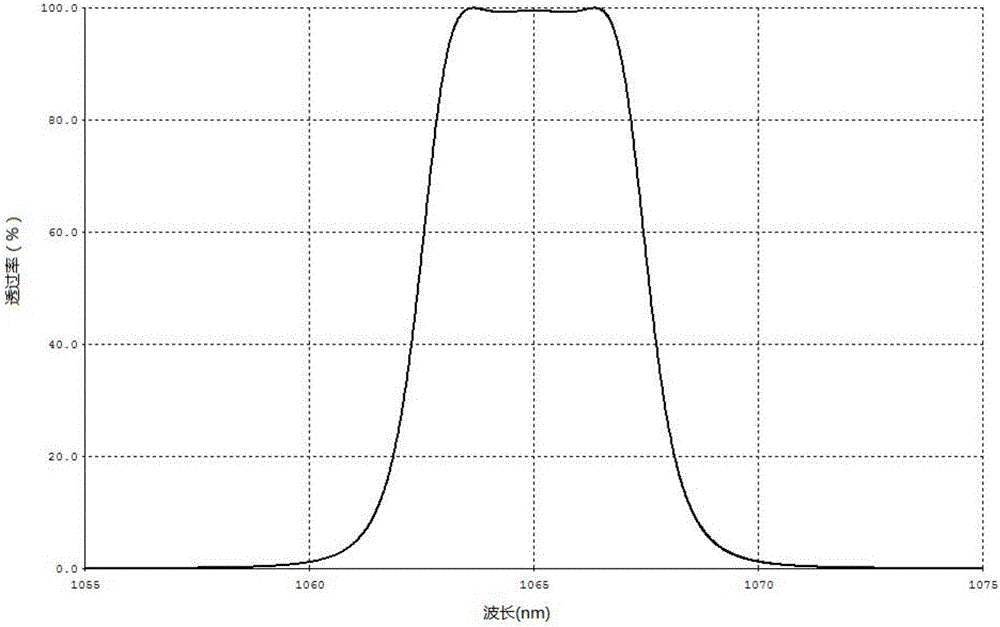

Method for making rectangular deep cut-off ultra-narrow band pass filter

A manufacturing method and technology of optical filters, applied in the direction of optical filters, optics, optical elements, etc., can solve the problems of transmittance changes, unfavorable stability, poor cut-off, etc., and achieve the reduction of control errors and large effective area And good uniformity, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

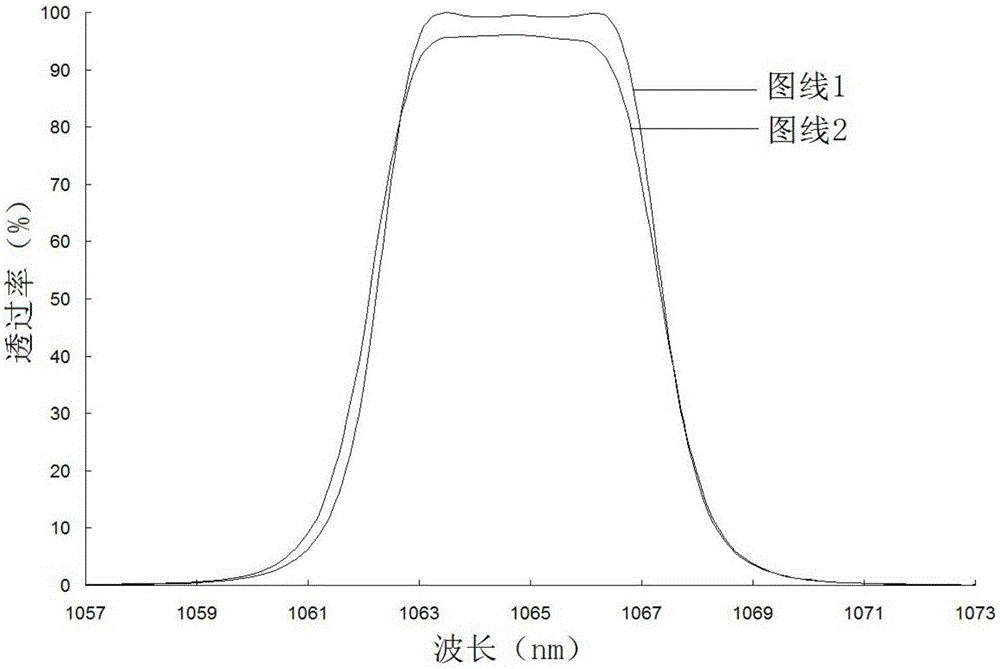

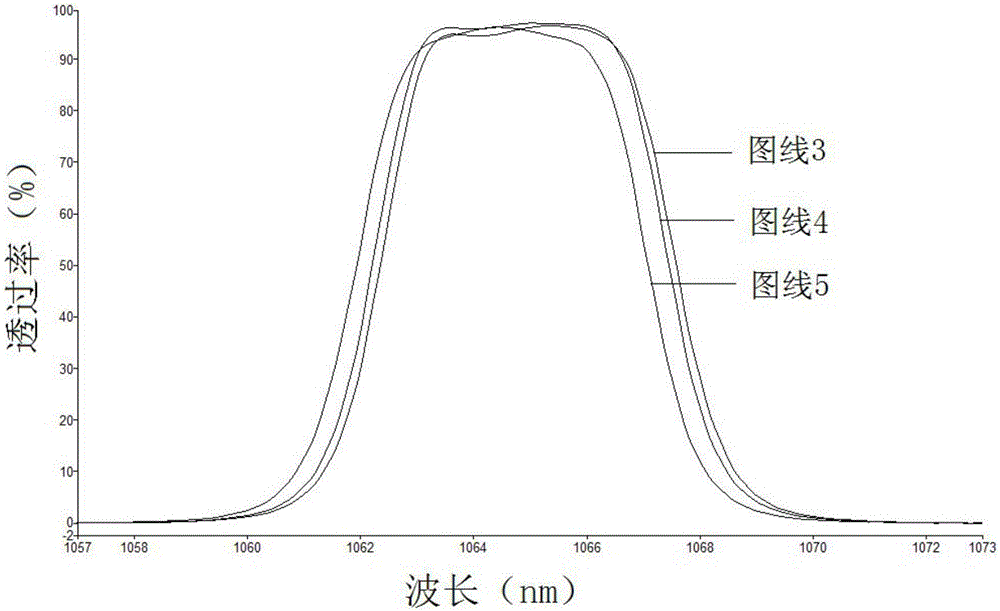

[0041] The manufacture method of the rectangular deep cut-off ultra-narrowband bandpass filter provided by the invention comprises the following steps:

[0042] (1) To determine the theoretical film system, based on the typical film structure of the multi-cavity filter, select Ta 2 o 5 As a high refractive index material, SiO 2 is a low refractive index material, define Ta respectively 2 o 5 and SiO 2 The unit optical thickness of λ / 4 is H and L, and the film structure of the filter is determined according to the pre-required performance parameters of the ultra-narrow band pass filter;

[0043] (2) Using a fully automatic coating machine with a quartz crystal oscillator film thickness controller, a high-precision o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com