Leg drilling device for orthopedic treatment use

A punching device and leg technology, which are applied in application, medical science, bone drill guidance, etc., can solve the problems of insufficient punching accuracy, inconvenient treatment work, and inability to accurately understand the speed at which the drill bit descends. Accurate, accurate punch location and quick results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

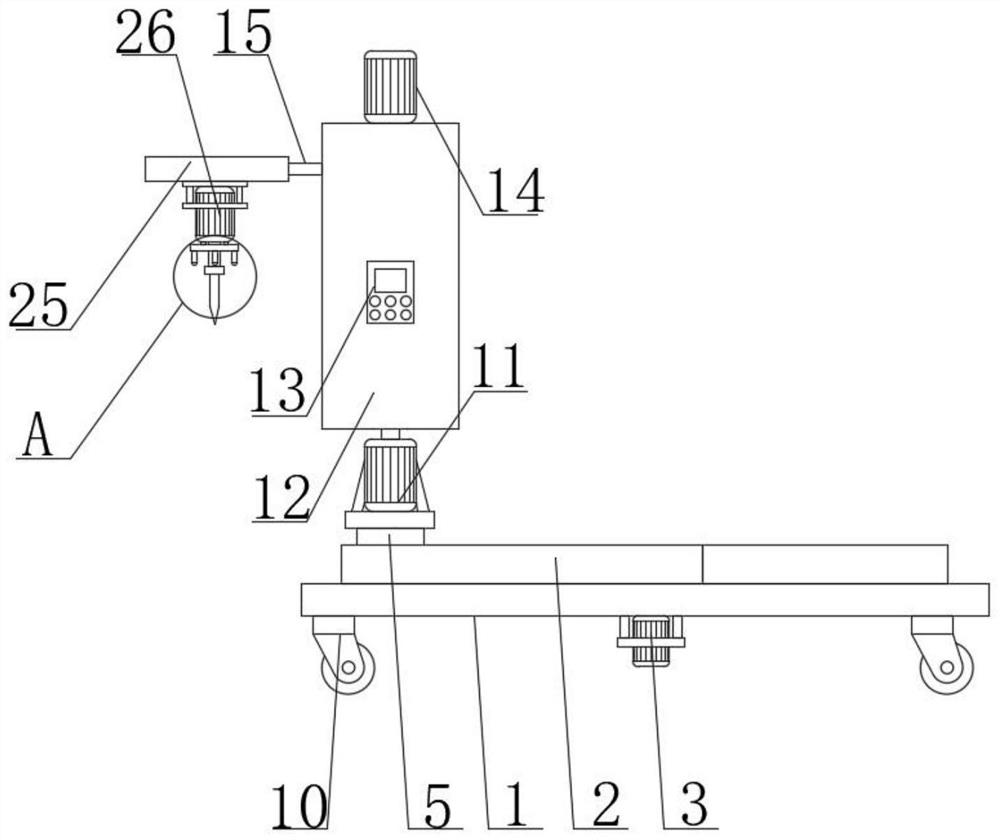

[0027] see figure 1 , figure 2 , Figure 4 and Figure 5 , a leg punching device for orthopedic treatment, a leg punching device for orthopedic treatment, comprising a base 1; a first housing 2; a second housing 12; and a drilling motor 26; on the base 1 The first housing 2 is fixedly connected, and the first housing 2 is connected with the second housing 12 through an adjustment mechanism; the second housing 12 is rotatably connected with a threaded rod 24, and the threaded rod 24 wears After passing through the second housing 12, it is fixedly connected with the output shaft of the third motor 14, and the third motor 14 is fixedly connected on the second housing 12; the threaded rod 24 is threaded with a nut block 21, and the The nut block 21 is fixedly embedded in the lifting block 20; one end of the lifting block 20 is rotatably connected to the second gear 17 through the mounting base 18, and the speed sensor 19 is fixedly connected to the mounting base 18, and the sp...

Embodiment 2

[0038]As a preferred solution of Embodiment 1, please refer to figure 1 , Figure 6 and Figure 7 , the adjustment mechanism includes a slider 4, a first rack 8 and a second motor 11, the slider 4 is slidably connected in the first housing 2, and one end of the slider 4 is symmetrically fixedly connected with two The first rack 8, two first gears 9 are symmetrically rotatably connected in the first housing 2, and the two first gears 9 mesh with each other; the bottom end of the base 1 is also fixedly connected with a first Motor 3, and the output shaft of the first motor 3 passes through the first housing 2 and is coaxially fixedly connected with the first gear 9; the top of the slider 4 is fixedly connected with the second motor 11 through the connecting column 5, so The connecting column 5 is slidably connected to the first housing 2 through the sliding opening 30, and the output shaft of the second motor 11 is fixedly connected to the second housing 12; the second motor 1...

Embodiment 3

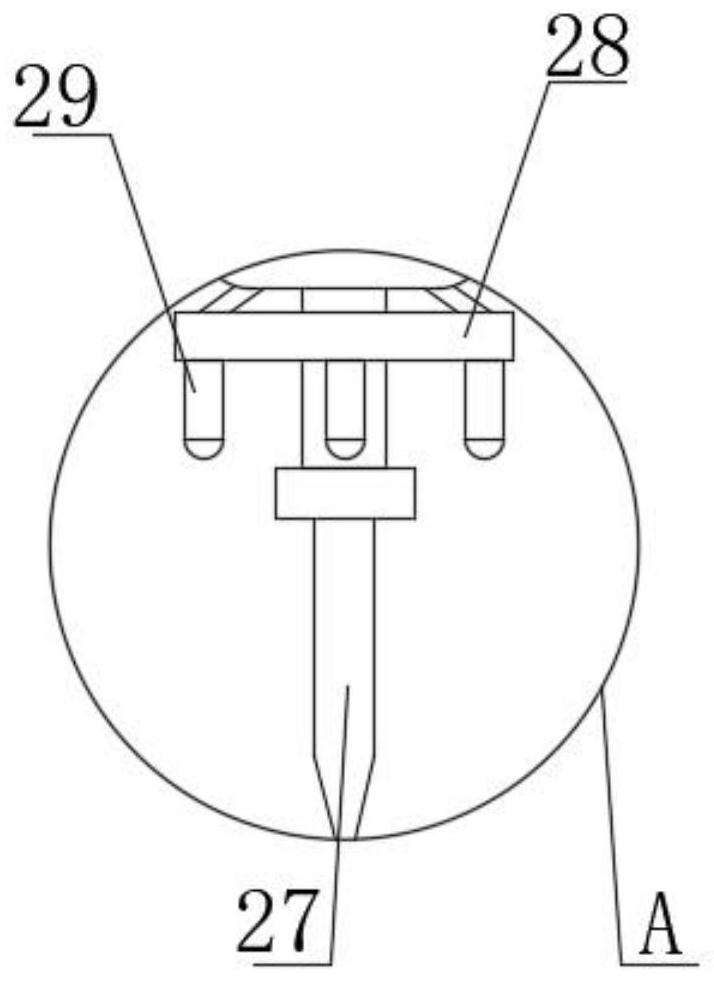

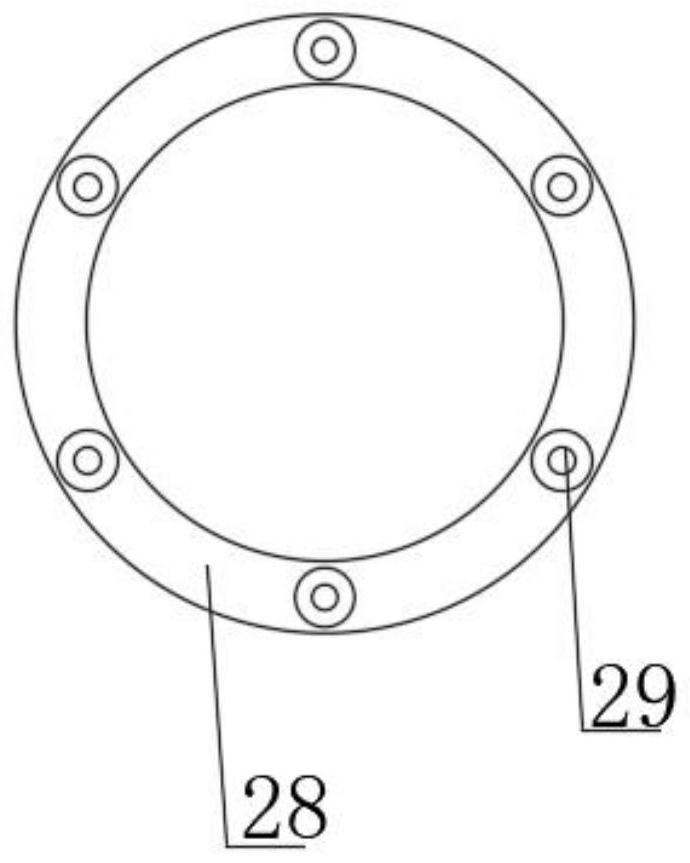

[0048] As a preferred solution of Embodiment 1 or Embodiment 2, please refer to figure 1 , figure 2 and image 3 , the bottom end of the drilling motor 26 is also fixedly connected with a fixed ring 28, and the fixed ring 28 is located at the outer end of the output shaft of the drilling motor 26, and the bottom end of the fixed ring 28 is uniformly fixedly connected with several Laser pointer 29;

[0049] Wherein, the laser pointer 29 can emit laser lines;

[0050] Working principle: when the drill bit 27 descends, by starting the laser pointer 29, the rays emitted by several laser pointers 29 form a circular ring-shaped structure, and then align the circular ring-shaped structure with the center position of the patient to be punched, and then When drilling through the drill bit 27, the position to be drilled is set at the center of the circular ring structure formed by the laser line, so that the drill bit 27 can be drilled more accurately.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com