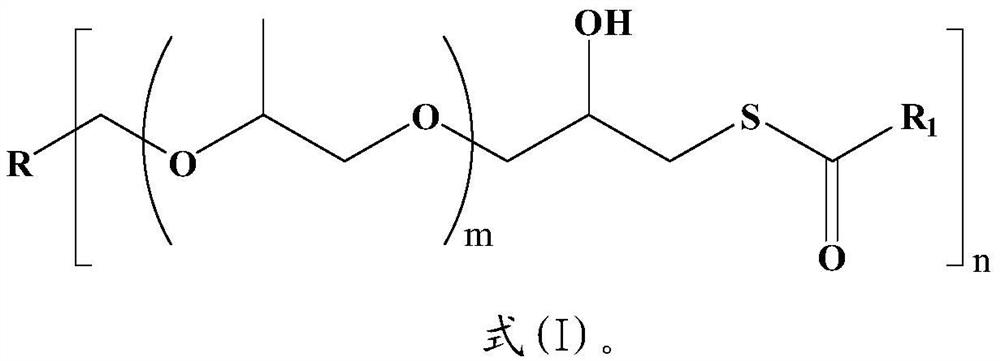

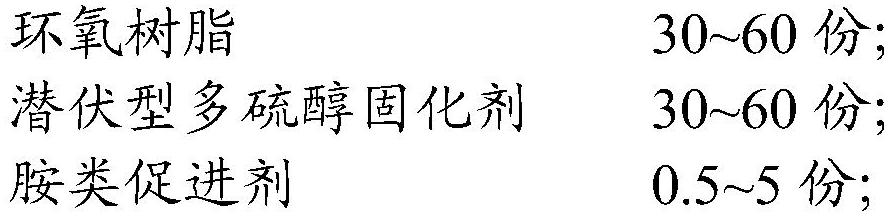

Latent macromolecular polymercaptan curing agent as well as preparation method and application thereof

A macromolecular and latent technology, applied in the direction of organic chemistry, can solve the problems of low thiol activity, difficulty in ensuring low temperature storage time, high curing temperature, etc., and achieve low curing temperature, easy transportation and use, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of latent macromolecular polythiol curing agent, its concrete steps are as follows:

[0033] 1) Take 89.6g of polyether polyol (PO) with triethylene glycol as the starting material and 0.46g of Lewis acid catalyst (Cat.-1), raise the temperature to dissolve the catalyst completely, and then add 67.2g of Epichlorohydrin (EPCH), the reaction temperature is controlled at 80°C during the dropwise addition, and the reaction time is 6 hours. After the reaction is completed, the intermediate product chlorinated polyether (PCE) is obtained;

[0034] 2) Add 400 g of the generated chlorinated polyether to NaOH solution with a concentration of 10 wt %, the reaction time is 3 hours, and the reaction temperature is 20° C. After the reaction, the generated salt is filtered to obtain a polyether polyol epoxy compound ;

[0035] 3) react the polyether polyvalent epoxy compound obtained in the previous step with 60.7g thioacetic acid, the reaction temperature is 30...

Embodiment 2

[0037] A preparation method of latent macromolecular polythiol curing agent, its concrete steps are as follows:

[0038]1) Take 92g of polyether polyol (PO) with trimethylolpropane as the starting material and 0.5g of Lewis acid catalyst (Cat.-1), raise the temperature to dissolve the catalyst completely, then add 66.4g of it dropwise to the reaction liquid Epichlorohydrin (EPCH), the reaction temperature is controlled at 80°C during the dropwise addition, and the reaction time is 6 hours. After the reaction is completed, the intermediate product chlorinated polyether (PCE) is obtained;

[0039] 2) Add 400 g of the generated chlorinated polyether to NaOH solution with a concentration of 10 wt %, the reaction time is 3 hours, and the reaction temperature is 20° C. After the reaction, the generated salt is filtered to obtain a polyether polyol epoxy compound ;

[0040] 3) React the polyether polyvalent epoxy compound obtained in the previous step with 63.7g of thiopropionic aci...

Embodiment 3

[0042] A preparation method of latent macromolecular polythiol curing agent, its concrete steps are as follows:

[0043] 1) Take 96.5g of polyether polyol (PO) with pentaerythritol as the starting material and 0.52g of Lewis acid catalyst (Cat.-1), after heating up to dissolve the catalyst, add 66.8g of epoxy resin dropwise to the reaction solution Chloropropane (EPCH), the reaction temperature is controlled at 80°C during the dropwise addition process, and the reaction time is 6 hours. After the reaction is completed, the intermediate product chlorinated polyether (PCE) is obtained;

[0044] 2) Add 400 g of the generated chlorinated polyether to NaOH solution with a concentration of 10 wt %, the reaction time is 3 hours, and the reaction temperature is 20° C. After the reaction, the generated salt is filtered to obtain a polyether polyol epoxy compound ;

[0045] 3) react the polyether polyvalent epoxy compound obtained in the previous step with 81.2g thioacetic acid, the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com