Foaming type structural adhesive and preparation method thereof

A foaming, structural adhesive technology, applied in the direction of adhesives, epoxy resin adhesives, adhesive types, etc., can solve the problems of easy slippage or falling off, unable to achieve effective bonding, etc., and achieve good foaming ratio, The effect of reducing labor cost and high mechanical bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

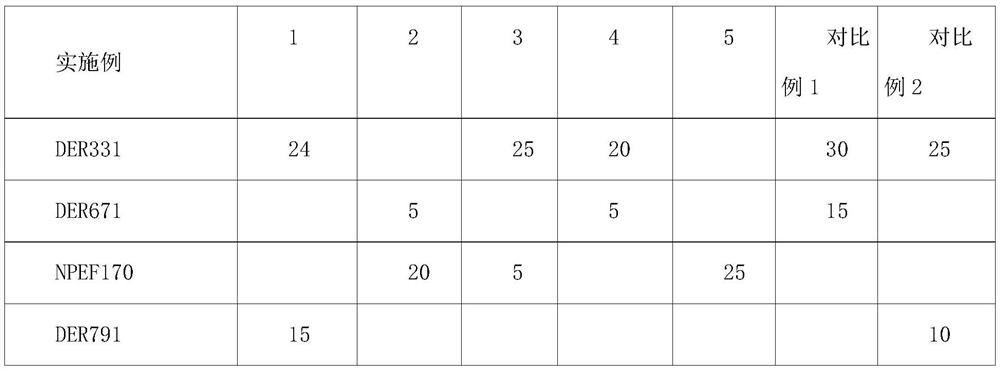

[0020] The technical solutions of the present invention will be clearly and completely described below through specific embodiments.

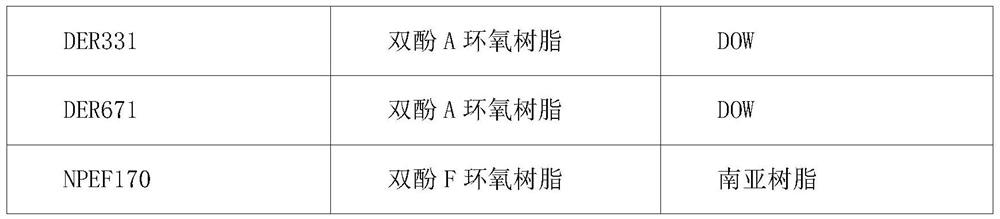

[0021] The following materials were used in the examples.

[0022]

[0023]

[0024] The rest of the reagents are routinely commercially available.

[0025] A preparation method of foamed structural adhesive, comprising the following steps:

[0026] (1) Take raw materials according to the weight percentage of each component in Table 1:

[0027] (2) Add epoxy resin and phenoxy resin into a vacuum planetary mixer and stir at 60°C-70°C until completely dissolved to obtain a liquid mixture.

[0028] (3) Add the above liquid mixture and toughening resin into a vacuum planetary mixer, and mix uniformly at 50°C-70°C; then add fillers therein, and mix uniformly at 40°C-50°C.

[0029] (4) Lower the temperature to 30°C-40°C and add curing agent and accelerator respectively for stirring. After stirring evenly, add foaming agent and foaming accele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cure temperature | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| foaming ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com