Lithium ion negative electrode material and preparation method thereof and lithium ion battery

A negative electrode material, lithium ion technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of large theoretical capacitance, good cycle performance, high energy density, etc., to improve the rate performance, increase the amount of lithium intercalation, good Effect of Magnification Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] As described in the background art, the existing lithium-ion batteries made of silicon-containing anode materials cannot meet the requirements of high energy density, large theoretical capacitance and good cycle performance at the same time. In order to solve the above-mentioned technical problems, the present application provides a preparation method of a lithium ion negative electrode material. The preparation method of the lithium ion negative electrode material includes: mixing conductive fibers and a silicon carbon composite material with a dispersant to form a suspension, and then mixing the suspension The liquid is spray-dried to obtain a composite; the composite is sintered to obtain a negative electrode material with a fibrous porous structure; and metal lithium is deposited on the surface of the negative electrode material to obtain a lithium ion negative electrode material.

[0023] In the above preparation method, the conductive fiber and the silicon-carbon c...

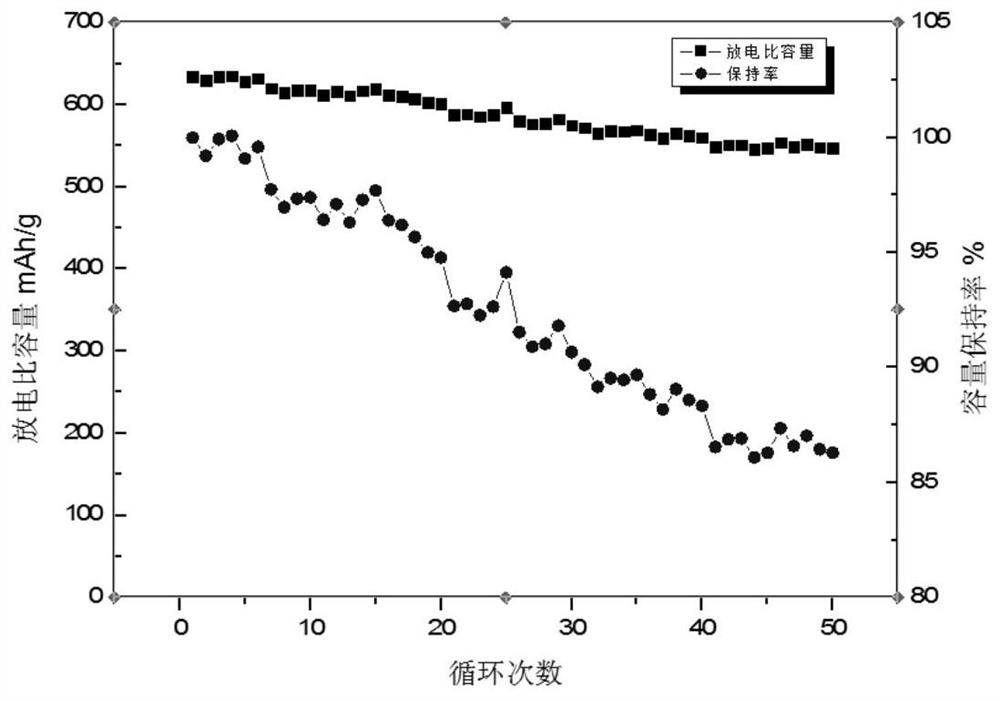

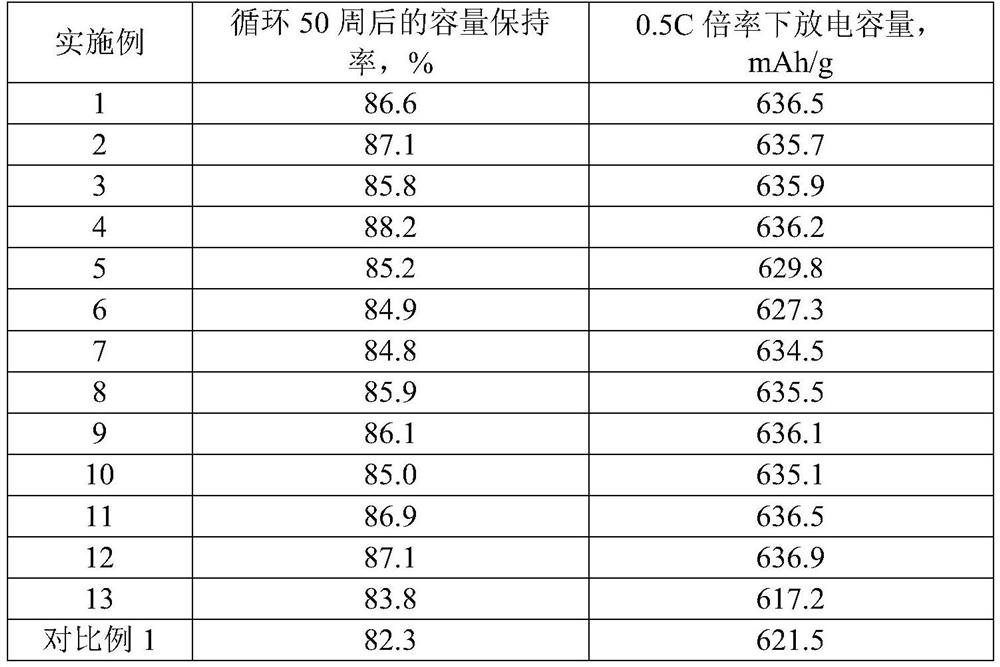

Embodiment 1

[0041] A preparation method of a lithium ion negative electrode material, comprising:

[0042] The conductive carbon nanotubes (15 nm in diameter and 200 μm in length) with a weight ratio of 1:0.3 and a silicon-carbon composite (the weight ratio of carbon to silicon in the silicon-carbon composite is 1:0.05) were dissolved in a certain amount of acetone , form a suspension; spray-dry the suspension: when the inlet temperature is 250°C, the suspension is passed through a 0.5mm nozzle and sprayed at a flow rate of 30mL / min, the outlet temperature is 150°C, and 50L / h of air is used. Atomization to obtain a composite of fibrous microporous structure.

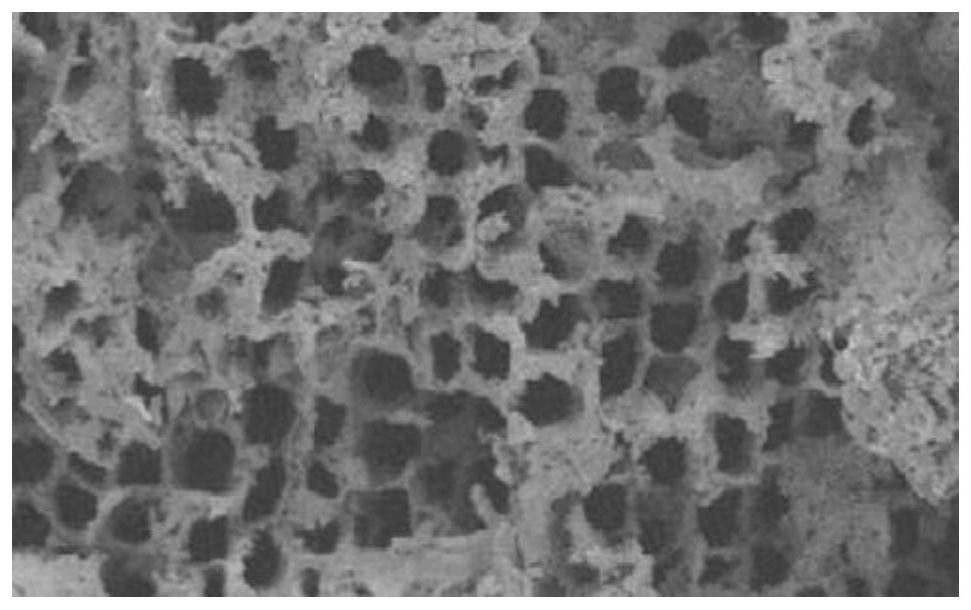

[0043] The composite with dimensional microporous structure was sintered in a tube furnace, sintered at 1000 °C for 15 h, and then cooled naturally with the furnace to obtain a negative electrode material with a fibrous porous structure. In the negative electrode material of the fibrous porous structure, the pore size of macropores...

Embodiment 2

[0047] A preparation method of a lithium ion negative electrode material, comprising:

[0048] The conductive carbon nanotubes with a weight ratio of 1:0.5 (15 nm in diameter and 200 μm in length) and silicon-carbon composites (the weight ratio of carbon to silicon in the silicon-carbon composites are 1:0.05) were dissolved in a certain amount of acetone , form a suspension; spray-dry the suspension: at an inlet temperature of 250°C, pass the suspension through a 0.5mm nozzle and spray it at a flow rate of 30ml / min, at an outlet temperature of 150°C, use 50L / h of air Atomization to obtain a composite of fibrous microporous structure.

[0049] The composite with dimensional microporous structure was sintered in a tube furnace, sintered at 1000 °C for 15 h, and then cooled naturally with the furnace to obtain a negative electrode material with a fibrous porous structure. In the negative electrode material with fibrous porous structure, the pore size of macropores is 50-100 nm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com