Bismuth phosphate cathode material with good conductivity for lithium battery and preparation method thereof

A positive electrode material, bismuth phosphate technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of poor conductivity of bismuth phosphate, etc., to increase the amount of lithium intercalation, improve the efficiency of charge transfer, and improve the efficiency of chemical conversion reactions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Add 1mol of bismuth nitrate pentahydrate into 6.7L of dilute nitric acid with a pH value of 2, stir at room temperature until completely dissolved to obtain a bismuth source solution; add 1mol of ammonium phosphate into 8.3L of deionized water, stir at room temperature until completely dissolved , to obtain a phosphorus source solution; add 0.03mol o-dichlorobenzene to the bismuth source solution, ultrasonically disperse for 30 minutes, then add phosphorus source solution, add phosphoric acid solution dropwise to adjust the pH value to 2, place it in a constant temperature water bath at 50°C, and ultrasonically oscillate for 30 minutes , and then suction filtered and washed to obtain a bismuth phosphate precursor;

[0032] (2) Add 0.133 mol of lithium hydroxide and 0.4 mol of ammonium vanadate into 1L of deionized water, oscillate ultrasonically for 30 minutes, then add ammonia water dropwise to adjust the pH value to 8.5, and heat to boiling. After reacting for 40 m...

Embodiment 2

[0036](1) Add 1mol of bismuth nitrate pentahydrate into 6.7L of dilute nitric acid with a pH value of 2, stir at room temperature until completely dissolved to obtain a bismuth source solution; add 1mol of potassium phosphate into 8.3L of deionized water, stir at room temperature until completely dissolved , to obtain a phosphorus source solution; add 0.05mol o-dichlorobenzene to the bismuth source solution, ultrasonically disperse for 20 minutes, then add phosphorus source solution, add phosphoric acid solution dropwise to adjust the pH value to 3, place it in a constant temperature water bath at 40°C, and ultrasonically oscillate for 30 minutes , and then suction filtered and washed to obtain a bismuth phosphate precursor;

[0037] (2) Add 0.05mol of lithium carbonate and 0.3mol of ammonium vanadate into 1L of deionized water, oscillate ultrasonically for 20 minutes, then add ammonia water dropwise to adjust the pH value to 8.5, and heat to boiling. After reacting for 60 minu...

Embodiment 3

[0041] (1) Add 0.5mol of bismuth sulfate heptahydrate into 3.3L of dilute nitric acid with a pH value of 2, stir at room temperature until completely dissolved to obtain a bismuth source solution; add 1mol of sodium phosphate into 7L of deionized water, and stir at room temperature until completely dissolved , to obtain a phosphorus source solution; add 0.04mol o-dichlorobenzene to the bismuth source solution, ultrasonically disperse for 25 minutes, then add phosphorus source solution, add phosphoric acid solution dropwise to adjust the pH value to 3, place it in a constant temperature water bath at 45°C, and ultrasonically oscillate for 40 minutes , and then suction filtered and washed to obtain a bismuth phosphate precursor;

[0042] (2) Add 0.1 mol of lithium hydroxide and 0.3 mol of ammonium vanadate into 1L of deionized water, oscillate ultrasonically for 25 minutes, then add ammonia water dropwise to adjust the pH value to 8.5, and heat to boiling. After reacting for 50 m...

PUM

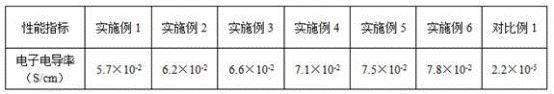

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com