Pencil lead

A pencil lead and core body technology, applied in pencil lead, non-moving pencil, printing and other directions, can solve the problems of low bending strength and easy breakage of pencil lead

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

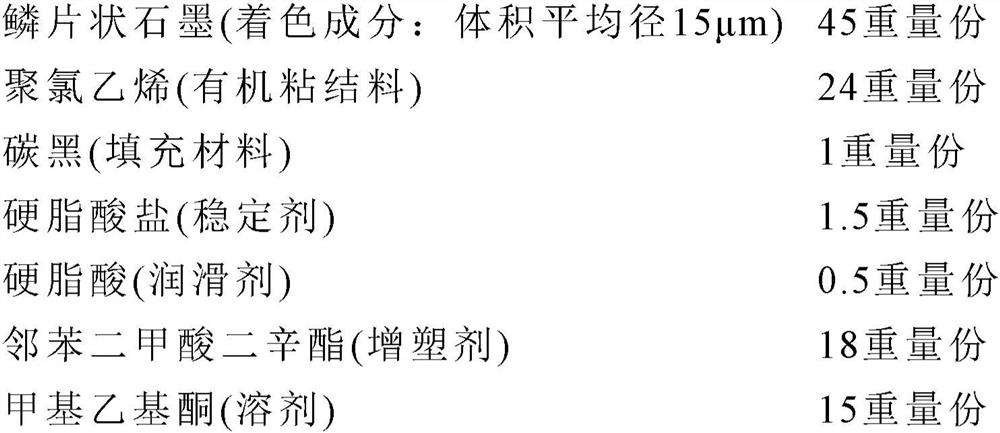

Embodiment 1

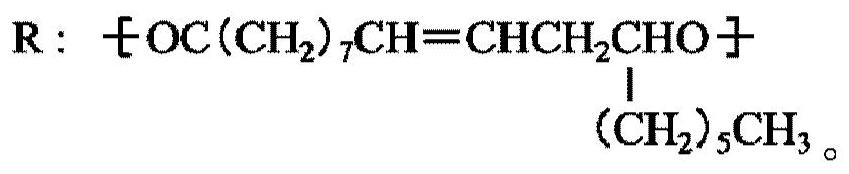

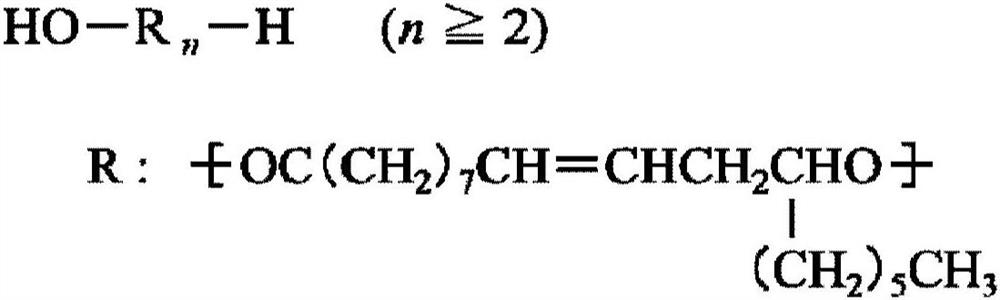

[0041] The impregnated component (K-PON 402, the compound (n=2) represented by the above-mentioned general formula (chemical formula 1) and the dehydration condensate of ricinoleic acid, heated at 120°C for the above-mentioned fired core body A, Ogura Sesei Kogyo ( Co., Ltd., IOB value = 0.45, viscosity 520mPa·s) after immersion for 16 hours, the excess impregnated components on the surface were removed by a centrifuge, thereby obtaining a pencil lead. The impregnation rate of the impregnation component was 16.5% by weight.

Embodiment 2

[0043] In addition to changing the impregnation component of Example 1 to K-PON 402, using K-PON 404-S (the compound (n=4) represented by the above general formula (chemical formula 1), a dehydration condensate of ricinoleic acid, Ogura Synthetic Industrial Co., Ltd., IOB value = 0.31, viscosity 1068mPa·s), except that it was carried out in the same manner as in Example 1 to obtain a pencil lead. The impregnation rate of the impregnation component was 16.7% by weight.

Embodiment 3

[0045] In addition to changing the impregnation component of Example 1 to K-PON 402, using K-PON 406-S (the compound (n=6) represented by the above general formula (chemical formula 1), a dehydration condensate of ricinoleic acid, Ogura Synthetic Industrial Co., Ltd., IOB value = 0.27, viscosity 1589mPa·s), except that it was carried out in the same manner as in Example 1 to obtain a pencil lead. The impregnation rate of the impregnation component was 16.2% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap