Halogenated butyl rubber plug coated with Teflon, profiling mold and production process

A technology of halogenated butyl rubber and Teflon coating, which is applied to the types of packaging items, special packaging items, medical containers, etc., can solve the problems of limited application, weak bonding, poor deformation performance, etc., and achieve compatibility Sexuality issues, excellent chemical stability, wide range of effects in pharmaceuticals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

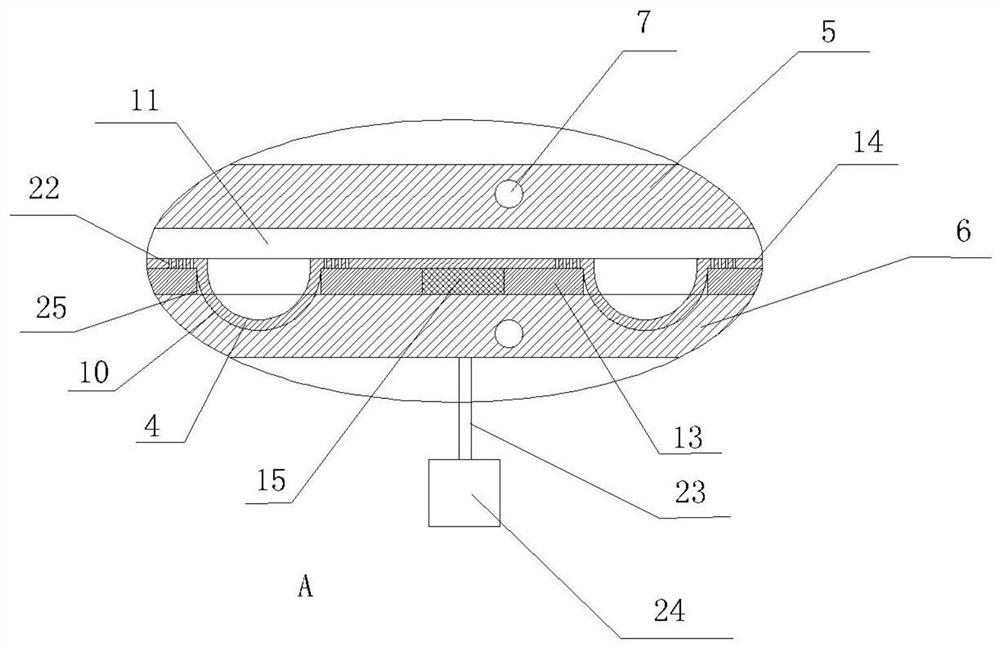

[0049] Such as Figure 5 As shown, the present invention discloses a halogenated butyl rubber stopper coated with Teflon, including a plug crown 16 and a plug neck 17 made of halogenated butyl rubber, the plug crown 16 includes an upper plug crown 19, and an annular lower plug crown 20 arranged below the upper plug crown 19, the plug neck 17 is covered with a Teflon film 26, and the upper end of the Teflon film 26 is bent outward to form a ring clip 27. The ring clip 27 is arranged between the upper plug crown 19 and the annular lower plug crown 20. The setting of the annular lower plug crown 20 of the present invention solves the sealing problem between the rubber stopper and the bottle mouth of the glass bottle.

[0050] Further, the ring clip 27 is provided with a plurality of microholes 22, and the microholes 22 are provided with a plurality of connecting columns 21, and the two ends of the connecting columns 21 are connected with the upper plug crown 19 and the annular l...

Embodiment 2

[0053] The invention discloses a production process of a Teflon-coated halogenated butyl rubber stopper, which is used to produce the Teflon-coated halogenated butyl rubber stopper described in Example 1, specifically comprising the following steps:

[0054] Step 1. The Teflon blank is made into a membrane material with a smooth bottom surface, a rough top surface, and concave-convex pits 4. The membrane material is punched out with several circles of micropores 22 on the edge of the concave-convex pit 4, and cut into block-shaped Teflon Diaphragm 14; the shape of the concave-convex pit 4 is adapted to the shape of the plug neck 17;

[0055] Among them, the Teflon blank is formed by Teflon resin after molding, sintering and cooling;

[0056] The process of making the Teflon blank into a membrane material with a smooth bottom surface, rough top surface, and concave-convex pits 4 is: after the Teflon blank is turned, it is rolled to make the bottom surface of the Teflon diaphrag...

Embodiment 3

[0071] The invention discloses a production process of a Teflon-coated halogenated butyl rubber stopper, which is used to produce the Teflon-coated halogenated butyl rubber stopper described in Example 1, specifically comprising the following steps:

[0072] Step 1. The Teflon blank is rolled to form a membrane material with a smooth bottom surface, a rough top surface, and concave-convex pits 4. The membrane material is punched out with several circles of micropores 22 on the edge of the concave-convex pit 4, and cut into block-shaped special Teflon diaphragm 14; the cross-section of the concave-convex pit 4 is arc-shaped; the diameter of the top of the concave-convex pit 4 is equal to the outer diameter of the plug neck 17.

[0073] Among them, the Teflon blank is formed by Teflon resin after molding, sintering and cooling;

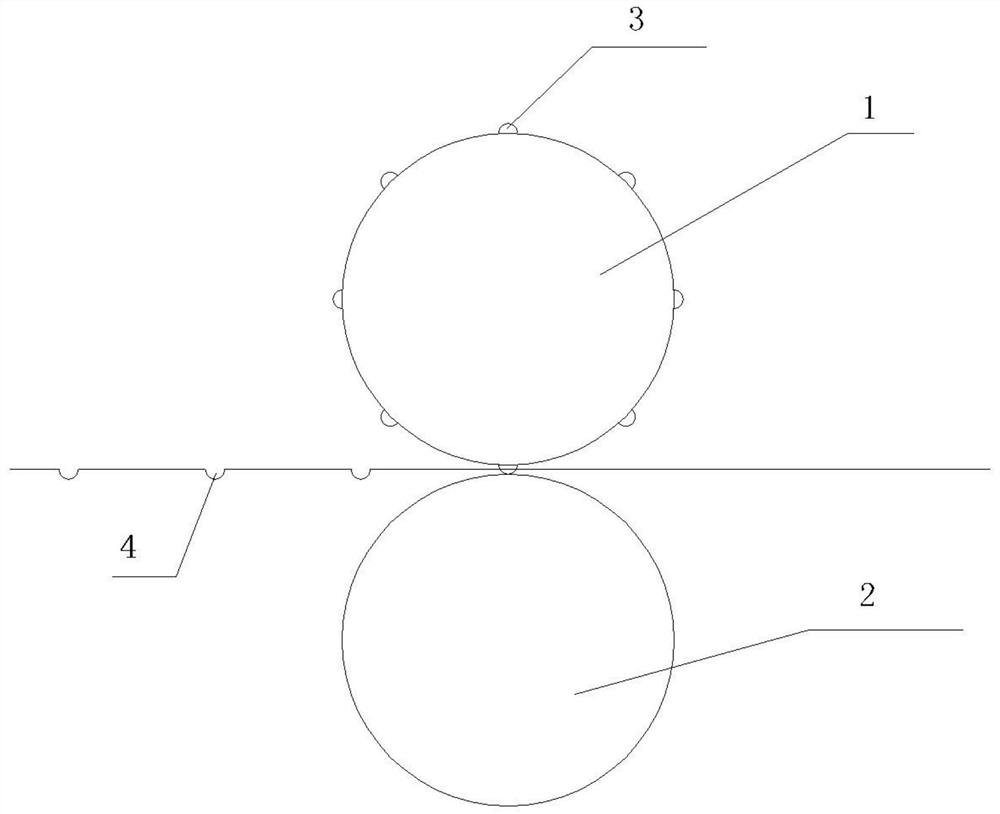

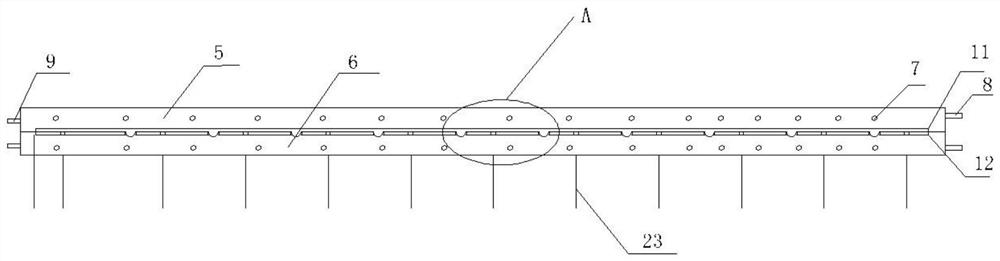

[0074] Such as figure 1 As shown, the roller surface of the upper roller 1 of the roller group used for calendering is a rough surface, and several pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com