Aluminum trichloride reacting furnace with good air tightness and using method thereof

A technology of aluminum trichloride and reaction furnace, which is applied in the direction of aluminum chloride, aluminum halide, etc., can solve the problems of increasing user's economic expenditure, unstable thermal insulation performance, and easy heat loss, etc., so as to prolong and reduce the internal heat existence time Dissipates internal heat and improves airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

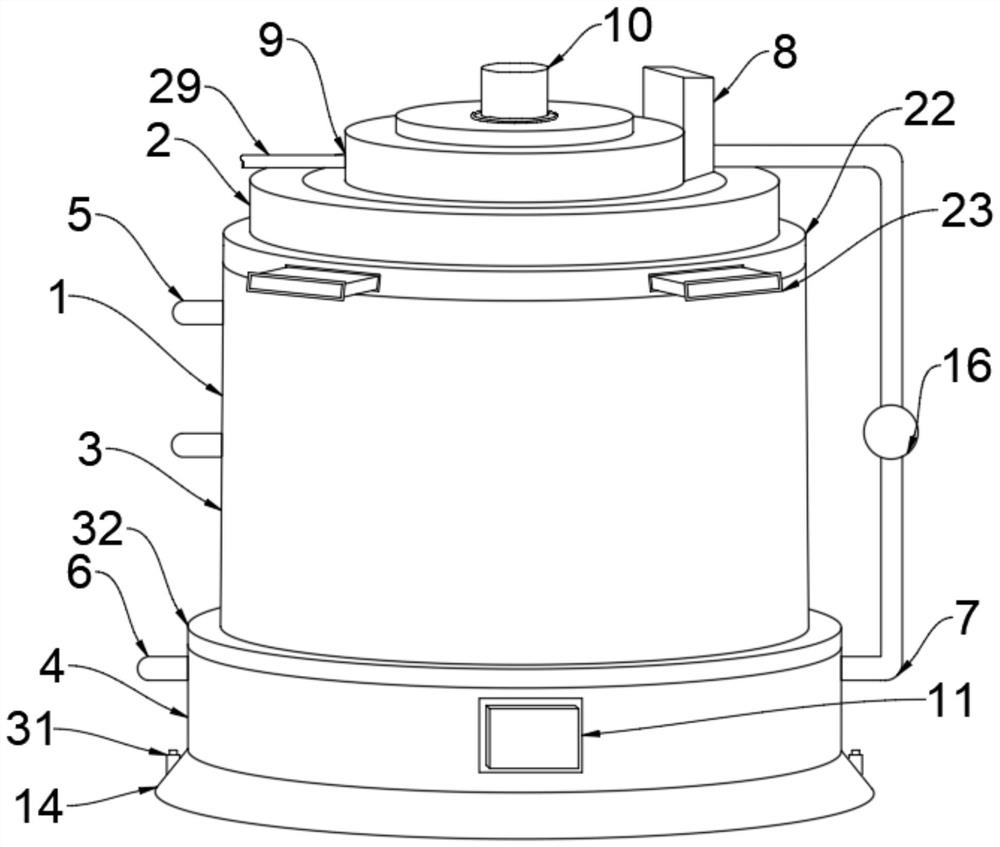

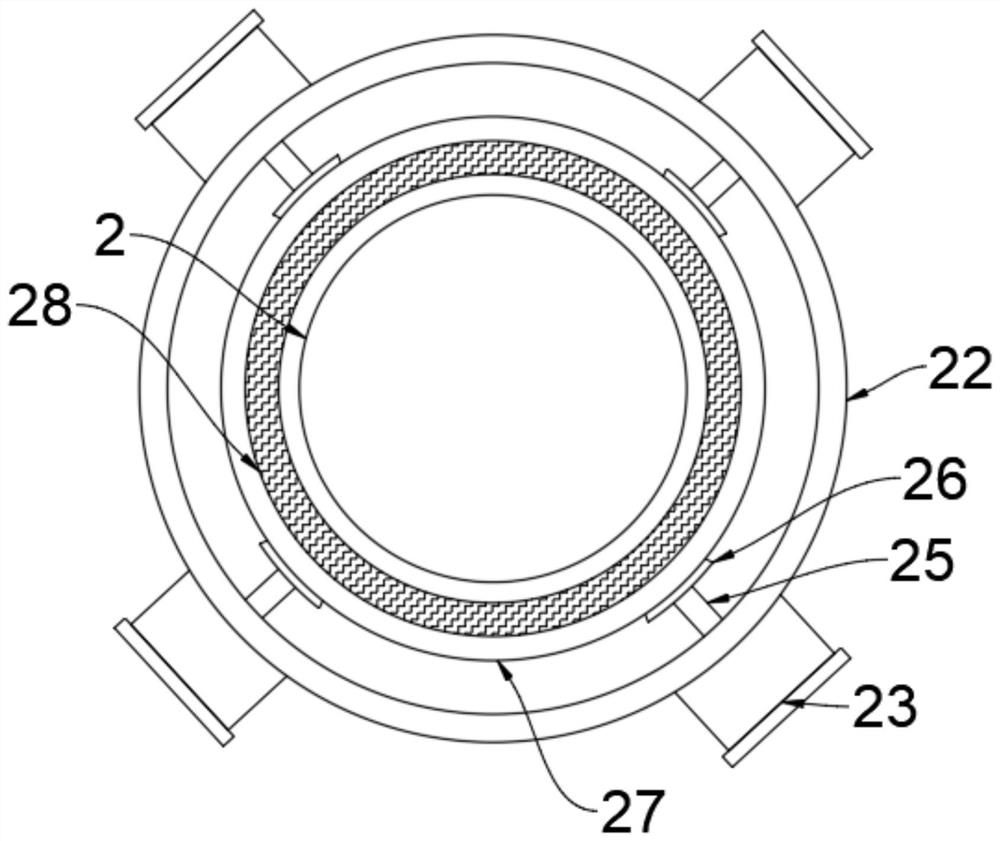

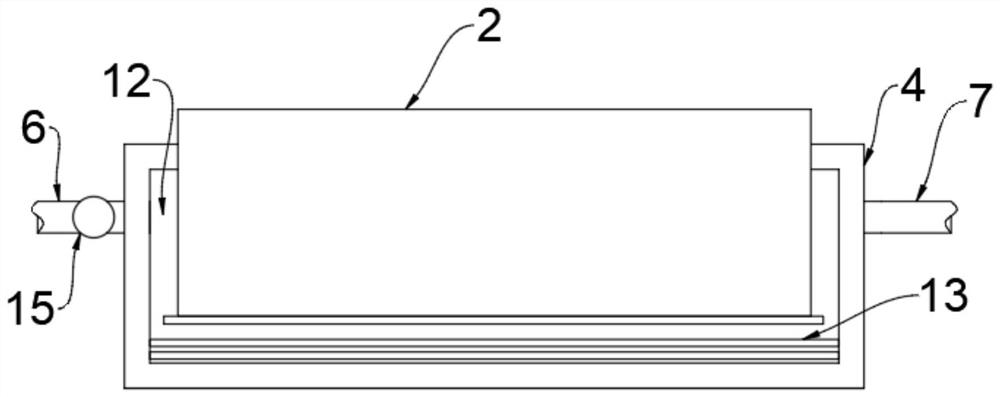

[0028] see Figure 1-5 , a kind of embodiment that the present invention provides: a kind of aluminum trichloride reaction furnace with good airtightness, comprises aluminum trichloride reaction furnace body 1, and aluminum trichloride reaction furnace body 1 is made of furnace inner tube 2, furnace outer cylinder 3 and furnace base 4, the upper end of the furnace outer cylinder 3 is equipped with a mounting mechanism 22, and the outer wall around the mounting mechanism 22 is equipped with drive boxes 23, and four drive boxes 23 are installed, and the inside of the drive box 23 is installed with Cylinder 24, the output end of the cylinder 24 is equipped with a pneuma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com