Preparation method of high-temperature-resistant basalt fiber

A technology of basalt fiber and high temperature resistance, which is applied in the field of fiber, can solve the problems of insufficient high temperature resistance of basalt fiber, and achieve the effects of enlarged drawing process range, increased peak temperature, and reduced high temperature viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

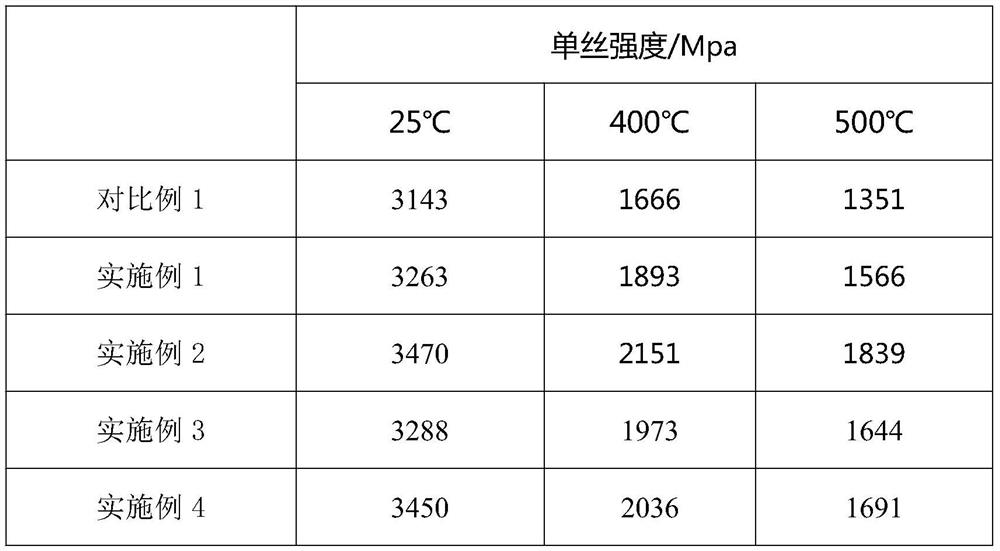

Examples

Embodiment 1

[0018] A preparation method of high temperature resistant basalt fiber, comprising the steps of:

[0019] (1) 160g of basalt ore is pulverized into 500 meshes to obtain ore powder, and in the ore powder, CeO is added to account for 1% of ore powder 2 , to obtain raw materials after mixing;

[0020] The basalt ore includes the following components in weight percentage: 52.39% SiO 2 , 12.61% Al 2 o 3 , 5.27% Fe 2 o 3 , 6.34% FeO, 6.23% CaO, 7.01% MgO, 2.91% Na 2 O, 1.52% K 2 O, 2.07% TiO 2 .

[0021] (2) heating and melting the raw materials, the melting temperature is 1500° C., and the melting time is 10 hours to prepare a basalt glass melt, and then flow it on a heat-resistant steel plate, and after cooling, a basalt glass block is obtained;

[0022] (3) Place the basalt glass block in a single-hole drawing crucible, adjust the temperature of the crucible to 1310°C, the height of the liquid level to 50mm, and the speed of the wire drawing machine to 1800r / min, and pre...

Embodiment 2

[0024] A preparation method of high temperature resistant basalt fiber, comprising the steps of:

[0025] (1) 160g basalt ore is pulverized into 500 meshes to obtain ore powder, add CeO accounting for 2% of ore powder in the ore powder 2 , to obtain raw materials after mixing;

[0026] The basalt ore includes the following components in weight percentage: 52.39% SiO 2 , 12.61% Al 2 o 3 , 5.27% Fe 2 o 3 , 6.34% FeO, 6.23% CaO, 7.01% MgO, 2.91% Na 2 O, 1.52% K 2 O, 2.07% TiO 2 .

[0027] (2) heating and melting the raw materials, the melting temperature is 1500° C., and the melting time is 10 hours to prepare a basalt glass melt, and then flow it on a heat-resistant steel plate, and after cooling, a basalt glass block is obtained;

[0028] (3) Place the basalt glass block in a single-hole wire drawing crucible, adjust the temperature of the crucible to 1320°C, the height of the liquid level to 50mm and the speed of the wire drawing machine to 1800r / min, and prepare basa...

Embodiment 3

[0030] A preparation method of high temperature resistant basalt fiber, comprising the steps of:

[0031] (1) 160g basalt ore is pulverized into 500 meshes to obtain ore powder, and in the ore powder, La 2 o 3 , to obtain raw materials after mixing;

[0032] The basalt ore includes the following components in weight percentage: 52.39% SiO 2 , 12.61% Al 2 o 3 , 5.27% Fe 2 o 3 , 6.34% FeO, 6.23% CaO, 7.01% MgO, 2.91% Na 2 O, 1.52% K 2 O, 2.07% TiO 2 .

[0033] (2) heating and melting the raw materials, the melting temperature is 1500° C., and the melting time is 10 hours to prepare a basalt glass melt, and then flow it on a heat-resistant steel plate, and after cooling, a basalt glass block is obtained;

[0034] (3) Place the basalt glass block in a single-hole wire drawing crucible, adjust the temperature of the crucible to 1305°C, the height of the liquid level to 50mm and the speed of the wire drawing machine to 1800r / min, and prepare basalt fibers through the cruci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com