Special liquid integrated oil phase emulsifier and preparation method thereof

A technology of emulsifier and polymer emulsifier, which is applied in the direction of offensive equipment, non-explosive/non-thermal agent components, explosives, etc., can solve the problems of short storage stability period of emulsion explosives, high process requirements, and low strength of emulsified oil film, etc., to achieve Excellent storage stability and explosive performance, simple preparation process requirements, and the effect of increasing thickness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

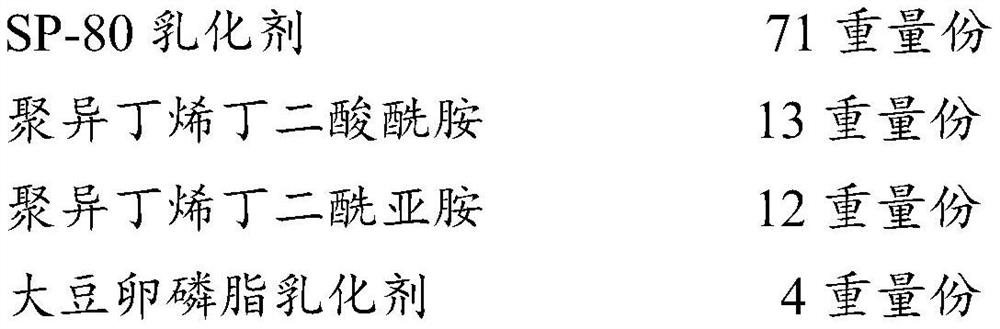

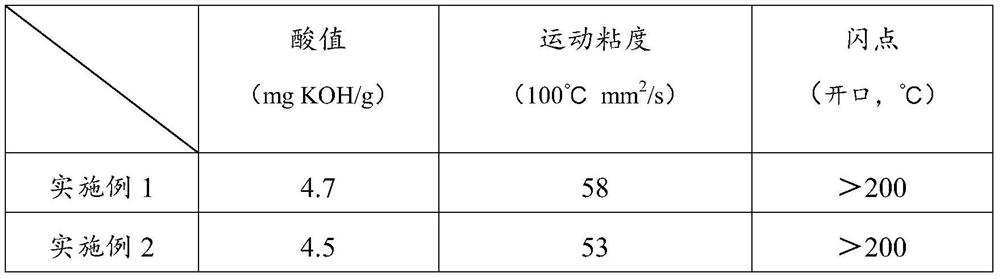

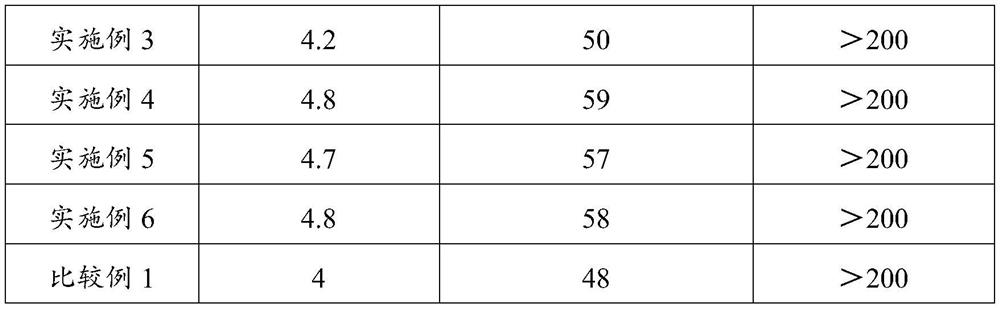

[0028] The present invention solves the problem that the emulsion explosive produced by the existing emulsifier has short storage stability period, complex preparation process and unfavorable production, and provides a liquid integrated oil with higher viscosity, lower acid value and enhanced interface strength The phase-specific emulsifier and the preparation method thereof, the emulsified explosive prepared by using the emulsifier described in the present invention has excellent storage stability and detonation performance, and the preparation process is simple, and is suitable for industrial production. In order to solve the above problems, the present invention firstly provides a special emulsifier for liquid integrated oil phase. In parts by weight, the raw materials include:

[0029] SP-80 emulsifier 71~80 parts by weight;

[0030] 14-25 parts by weight of polymer emulsifier;

[0031] Soybean lecithin emulsifier 0-9 parts by weight.

[0032] Among the above raw materia...

Embodiment 1

[0045] Example 1 Preparation of special emulsifier for liquid integrated oil phase

[0046] SP-80 emulsifier 71 parts by weight

[0047] 25 parts by weight of polyisobutylene succinate amine

[0048] 4 parts by weight of soybean lecithin emulsifier

[0049] When heating and mixing, first add 71 parts by weight of SP-80 emulsifier and 25 parts by weight of polyisobutylene succinate amine, stir and heat the temperature to 90°C, then add 4 parts by weight of soybean lecithin emulsifier, and then keep warm and stir for 2 hour, promptly get the described emulsifier specially used for the integrated oil phase of the liquid state.

Embodiment 2

[0050] Example 2 Preparation of special emulsifier for liquid integrated oil phase

[0051] SP-80 emulsifier 77 parts by weight

[0052] 14 parts by weight of polyisobutylene succinate amine

[0053] 9 parts by weight of soybean lecithin emulsifier

[0054] When heating and mixing, first add 77 parts by weight of SP-80 emulsifier and 14 parts by weight of polyisobutylene succinate amine, stir and heat the temperature to 89 ° C, then add 9 parts by weight of soybean lecithin emulsifier, and then keep warm and stir for 2 hour, promptly get the described emulsifier specially used for the integrated oil phase of the liquid state.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com