Test method and application method for nucleation growth rule of acicular ferrite in welding process

An acicular ferrite, welding process technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of poor welding performance, large fluctuation of welding performance, and inability to accurately control the weld area Deformation process and other problems, to achieve the effect of solving unstable weld performance, excellent steel welding performance, and improving welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

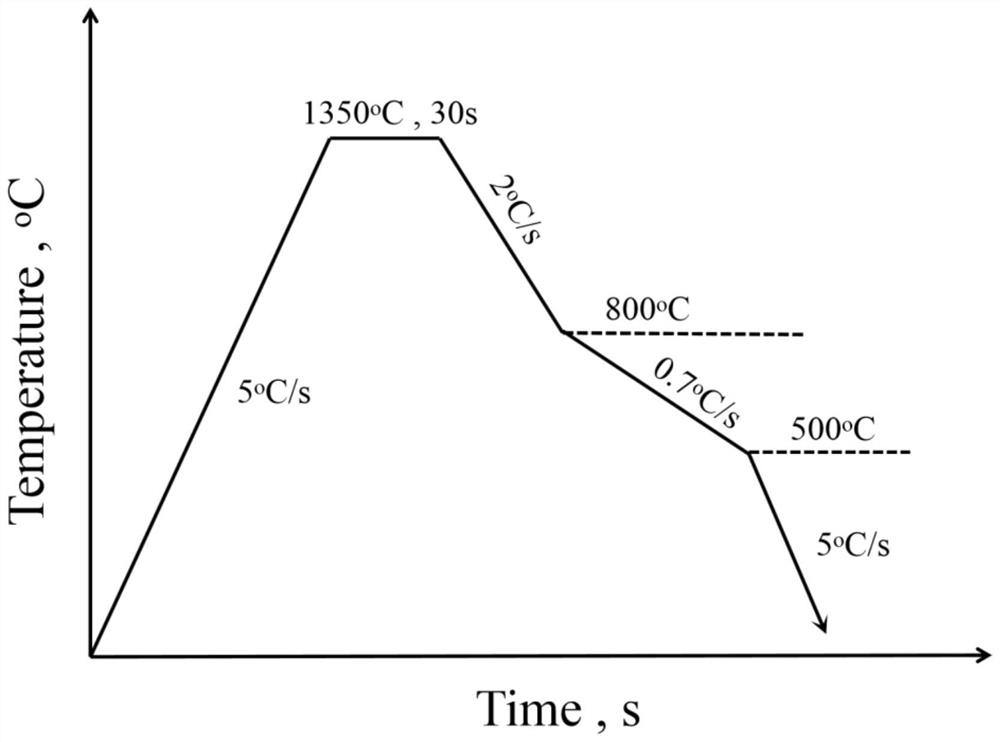

[0032] Process the EH420 ship plate steel into a cylindrical sample, polish it and place it in an alumina crucible; the diameter of the sample is 3mm, and the height is 5mm;

[0033] Place the alumina crucible in a high-temperature furnace, heat it to 1350±10°C at a heating rate of 5±0.1°C / s, and then keep it warm for 30s to complete the complete austenitization process and obtain a completely austenitized sample;

[0034] The fully austenitized sample is cooled for the first time to 800±10°C, and then the second time is lowered to 500±10°C;

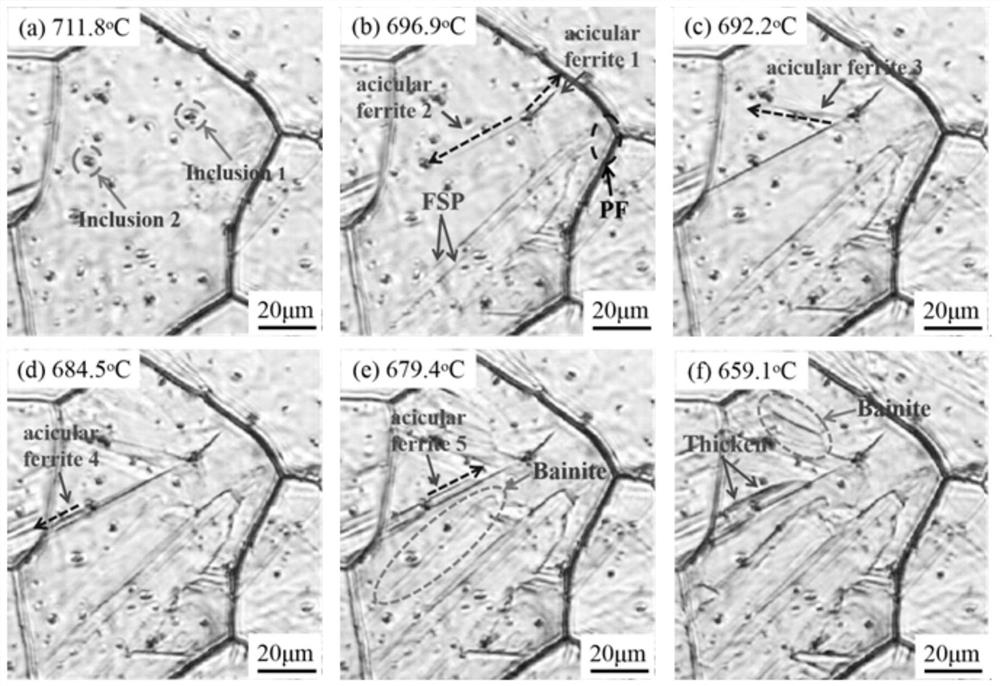

[0035] During the first cooling process, observe the sample through a high-temperature laser confocal microscope, take 5 photos per second for high-temperature in-situ observation, record the transformation process of austenite to acicular ferrite, and obtain the recorded results;

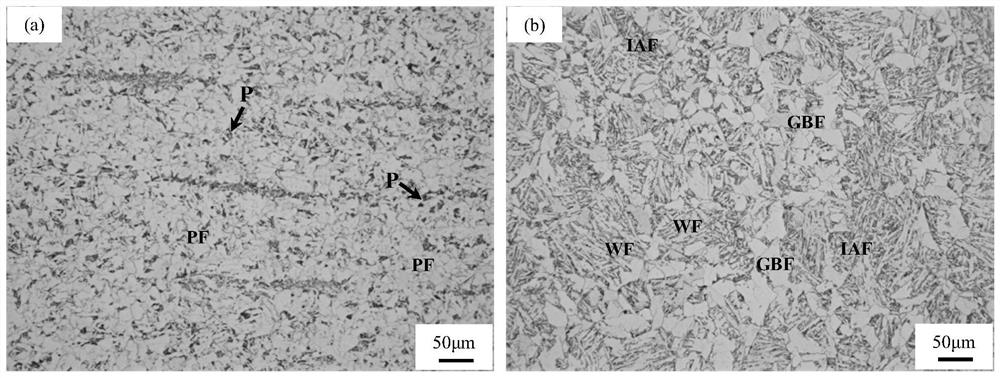

[0036] When the second cooling is over, the sample is cooled to room temperature at a cooling rate of 5±0.1°C / s to complete the simulation of the welding the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com