A method for sterilizing experimental consumables by irradiation

A technology of irradiation sterilization and experiments, applied in the direction of liquid cleaning methods, irradiation, chemical instruments and methods, etc., can solve the problems of ineffective sterilization of high-temperature-resistant strains, inability to promote, and harmfulness to human body, etc., to achieve The sterilization effect is remarkable, the irradiation time is short, and the effect of ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

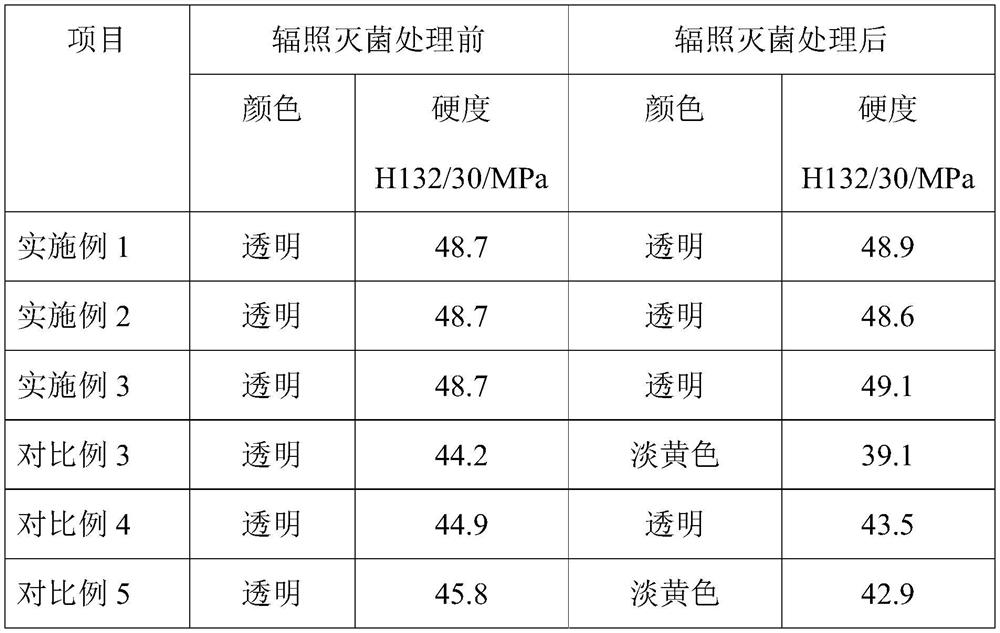

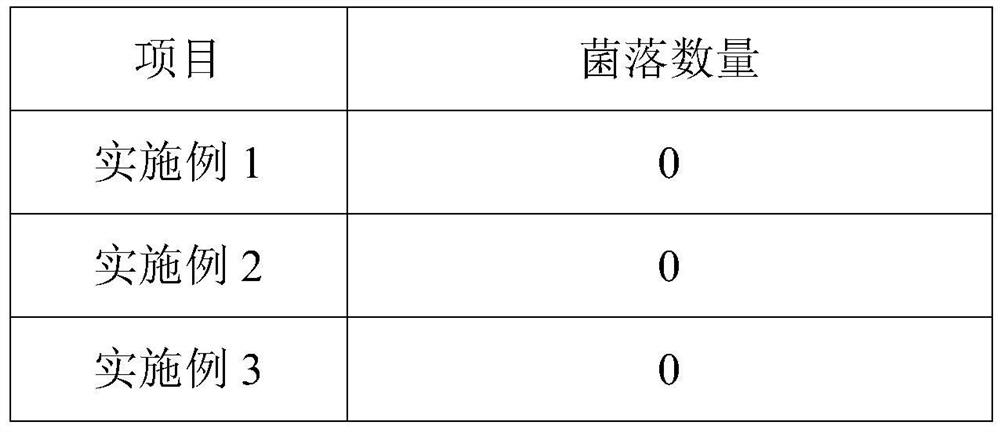

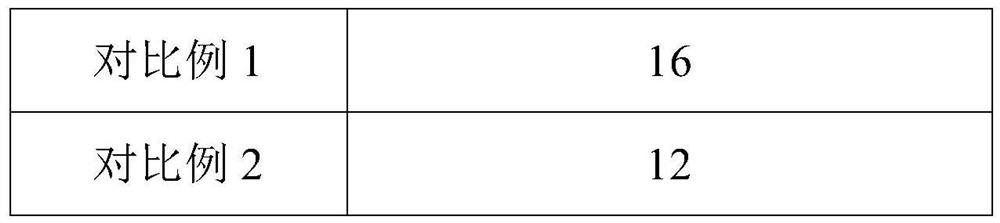

Examples

Embodiment 1

[0027] A method for sterilizing a petri dish by irradiation, comprising the steps of:

[0028] S01: The petri dish is cleaned by ultrasonic for the first time, the ultrasonic power is 80W, the ultrasonic frequency is 30kHz, and the ultrasonic power density is 7.1W cm -2 , the ultrasonic time is 2 minutes; the cleaning solution used in the first ultrasonic cleaning includes the following components in parts by weight: porous nano-silicon 6kg, sodium lauryl sulfate 6kg, ethylene glycol n-butyl ether 5kg, phenol 4kg, 0.5kg of isopropanol and 78.5kg of water; wherein, the light stabilizer is added to the polypropylene by the blending method in the petri dish, and the weight ratio of the light stabilizer to polypropylene is 0.5:100; : 1.5 of 1-(methyl)-8-(1,2,2,6,6-pentamethyl-4-piperidine) sebacate and bis(3,5-tertiary butyl-4- Hydroxyphenyl) sulfide composition.

[0029] S02: The petri dish is cleaned by ultrasonic for the second time, the ultrasonic power is 80W, the ultrasoni...

Embodiment 2

[0034] A method for sterilizing a petri dish by irradiation, comprising the steps of:

[0035] S01: The petri dish is cleaned by ultrasonic for the first time, the ultrasonic power is 80W, the ultrasonic frequency is 30kHz, and the ultrasonic power density is 7.1W cm -2 , the ultrasonic time is 2 minutes; the cleaning solution used in the first ultrasonic cleaning includes the following components in parts by weight: porous nano-silicon 7kg, sodium lauryl sulfate 4kg, ethylene glycol n-butyl ether 7kg, phenol 2kg, 1kg of isopropanol and 79kg of water; wherein, the light stabilizer is added to the polypropylene by the blending method in the petri dish, and the weight ratio of the light stabilizer to polypropylene is 1:100; the weight ratio of the light stabilizer is 1:3.5 1-(methyl)-8-(1,2,2,6,6-pentamethyl-4-piperidine) sebacate and bis(3,5-tertiary butyl-4-hydroxybenzene base) sulfide composition.

[0036] S02: The petri dish is cleaned by ultrasonic for the second time, th...

Embodiment 3

[0041] A method for sterilizing a petri dish by irradiation, comprising the steps of:

[0042] S01: The petri dish is cleaned by ultrasonic for the first time, the ultrasonic power is 80W, the ultrasonic frequency is 30kHz, and the ultrasonic power density is 7.1W cm -2 , the ultrasonic time is 2 minutes; the cleaning solution used in the first ultrasonic cleaning includes the following components in parts by weight: porous nano-silicon 6.5kg, sodium lauryl sulfate 5kg, ethylene glycol n-butyl ether 6kg, phenol 3kg , Virahol 0.8kg and water 78.7kg; Wherein, culture dish adopts blending method to add light stabilizer in polypropylene, the weight ratio of light stabilizer and polypropylene is 0.8:100; Light stabilizer is by weight ratio: 1:2.5 of 1-(methyl)-8-(1,2,2,6,6-pentamethyl-4-piperidinium) sebacate and bis(3,5-tertiary butyl-4 -Hydroxyphenyl) sulfide composition.

[0043] S02: The petri dish is cleaned by ultrasonic for the second time, the ultrasonic power is 80W, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com