Degradable plastic film and preparation method thereof

A technology for degrading plastics and plastics, applied in the field of degradable plastic films and their preparation, can solve problems such as phase separation, poor interface compatibility, and mechanical properties that cannot be effectively improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

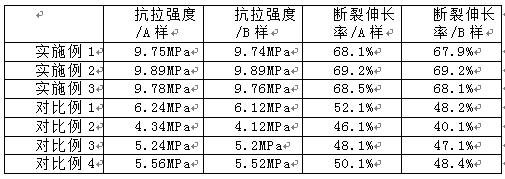

Examples

preparation example Construction

[0029] A method for preparing a degradable plastic film, the specific preparation steps comprising:

[0030] Preparation of the base plastic: Heat and blend polylactic acid and thermoplastic starch; then add metal-organic framework material, continue heating and blending, extrude and granulate to obtain the base plastic.

[0031] Further, the specific preparation steps include:

[0032] Preparation of thermoplastic starch: adding 1-5% D-sorbitol in the starch, heating and shearing to obtain thermoplastic starch;

[0033] Preparation of the base plastic: Heat and blend polylactic acid and thermoplastic starch; then add metal-organic framework material and graphene oxide, continue heating and blending, extrude and granulate to obtain the base plastic.

[0034] Further, the specific preparation steps include:

[0035] Preparation of raw materials: in parts by weight, sequentially take 100-200 parts of polylactic acid, 10-15 parts of metal-organic framework material, 20-80 parts...

Embodiment 1

[0042] Preparation of raw materials: in parts by weight, successively take 100 parts of polylactic acid, 10 parts of metal-organic framework material, 20 parts of thermoplastic starch; and graphene oxide with 0.1 times the quality of metal-organic framework material; the metal-organic framework In the material, the metal element is combined with the organic framework in a single atom state; the single atom is Cu;

[0043] Preparation of thermoplastic starch: Add D-sorbitol with 1% starch mass to the starch, add it to the reaction kettle, heat and shear for 1 hour at a temperature of 65°C, a pressure of 0.2MPa, and a shear rate of 2000r / min. , stop shearing, naturally cool to room temperature, and discharge to obtain thermoplastic starch; the starch is trimethylammonium chloride modified starch;

[0044] Preparation of matrix plastic: Pour polylactic acid and thermoplastic starch into a mixer, and add 1% of the mass of polylactic acid as an antioxidant and 1% of the mass of pol...

Embodiment 2

[0046] Preparation of raw materials: in parts by weight, successively take 150 parts of polylactic acid, 12 parts of metal-organic framework material, 50 parts of thermoplastic starch; and graphene oxide with 0.2 times the quality of metal-organic framework material; the metal-organic framework In the material, the metal element is combined with the organic framework in a single atom state; the single atom is Fe;

[0047] Preparation of thermoplastic starch: Add D-sorbitol with 3% starch mass to the starch, add it to the reaction kettle, heat and shear it for 1 hour at a temperature of 75°C, a pressure of 0.3MPa, and a shear rate of 3000r / min. , stop shearing, naturally cool to room temperature, and discharge to obtain thermoplastic starch; the starch is tetramethylammonium chloride modified starch;

[0048] Preparation of matrix plastic: Pour polylactic acid and thermoplastic starch into a mixer, and add 2% polylactic acid antioxidant and 2% polylactic acid plasticizer at a t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap