Micro-fluidic chip and manufacturing method thereof

A microfluidic chip and miniature technology, applied in the field of cell culture, can solve the problems of different in vivo environments, inability to get close to the process of cell growth and differentiation, and difficulty in realizing quantitative control of mechanical force, so as to expand the scope of application and achieve controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

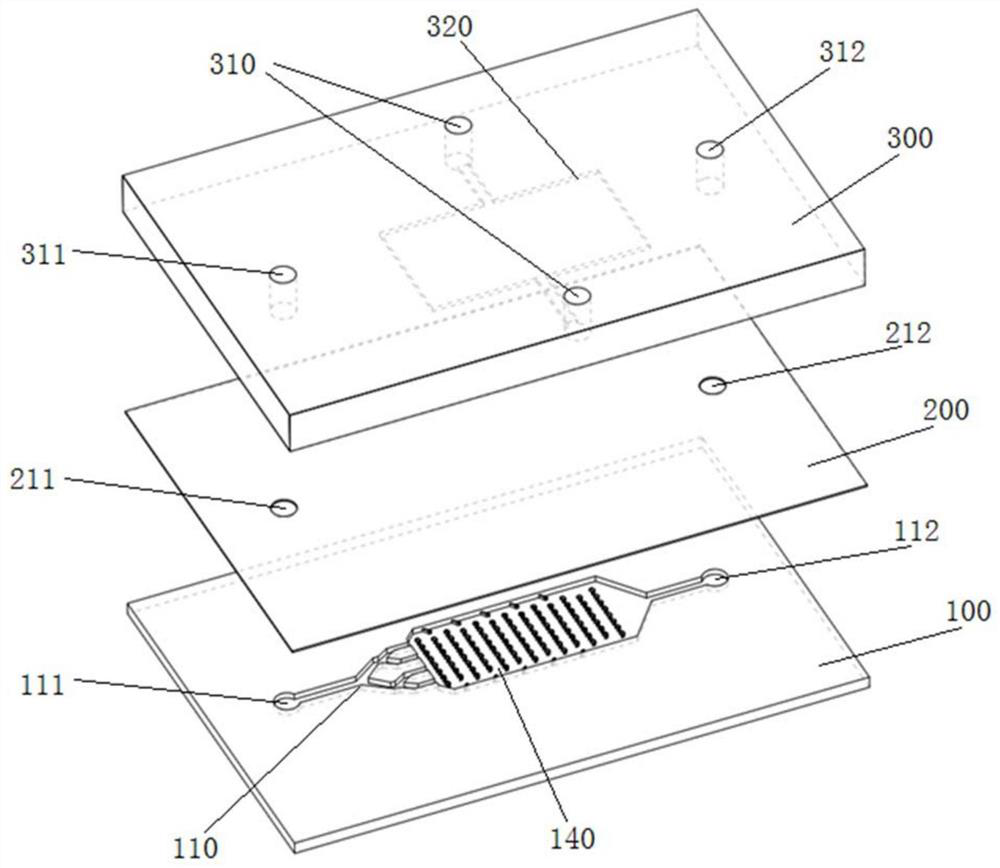

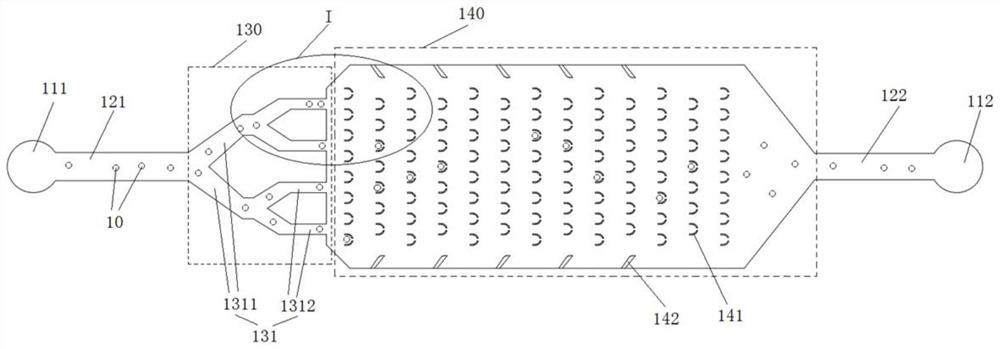

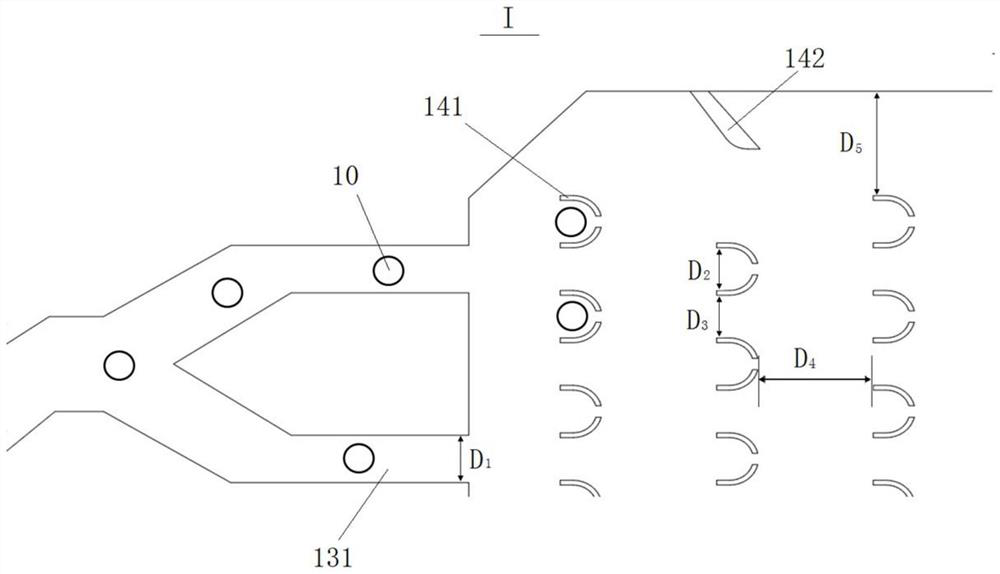

[0045] Refer below Figure 1 to Figure 5 The specific structure of the microfluidic chip of the embodiment of the present invention is described. The microfluidic chip provided by the embodiment of the present invention is suitable for the controllable growth of single cells and cell spheroids, biomechanical measurement and biomechanical conduction.

[0046] Such as figure 1 As shown, the microfluidic chip provided by the embodiment of the present invention includes: a capture layer 100, a deformable layer 200, and a pressure layer 300, the deformable layer 200 is disposed on the capture layer 100, and the pressure layer 300 is disposed on the row. . The capture layer 100 is provided with a capture channel 110, and the capture channel 110 is used to pass through a plurality of samples to be pressurized. In this embodiment, the sample to be pressurized can be a single cell or a cell sphere, and the cell sphere is composed of multiple cells. composed of spherical cell cluster...

Embodiment 2

[0060] Image 6 It is a schematic flow chart of a method for manufacturing a microfluidic chip provided in Embodiment 2 of the present invention. The method for manufacturing a microfluidic chip provided in this embodiment can manufacture a microfluidic chip provided in any embodiment of the present invention. This embodiment For the content not described in detail, reference may be made to the description in any embodiment of the microfluidic chip of the present invention.

[0061] Such as Image 6 As shown, the manufacturing method of the microfluidic chip provided by the embodiment of the present invention includes:

[0062] S610. Provide a capture layer, the capture layer includes a capture channel, and the capture channel is used to pass through a plurality of samples to be pressurized.

[0063] Specifically, a capture channel is provided in the capture layer, and the capture channel is used to pass through a plurality of samples to be pressurized. The capture channel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com