Method for Improving the Porous Structure and Texture of Vacuum Freeze-drying and Recombined Mango Chips

A technology of vacuum freeze-drying and porous structure, which is applied in the direction of food freezing, food drying, and the function of food ingredients. It can solve the problems of poor texture of recombined mango chips, so as to provide sublimation heat, shorten drying time, and improve quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

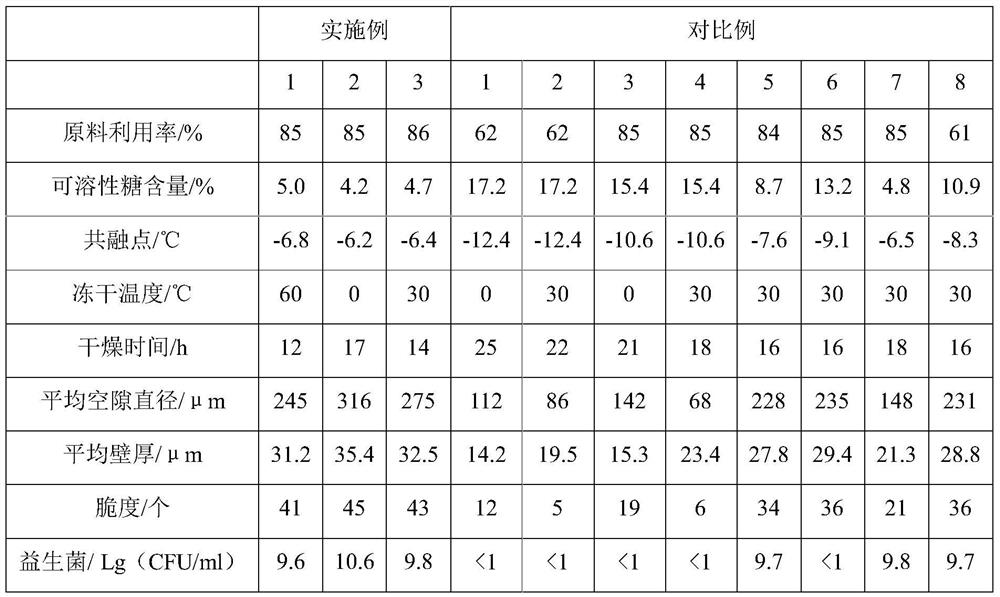

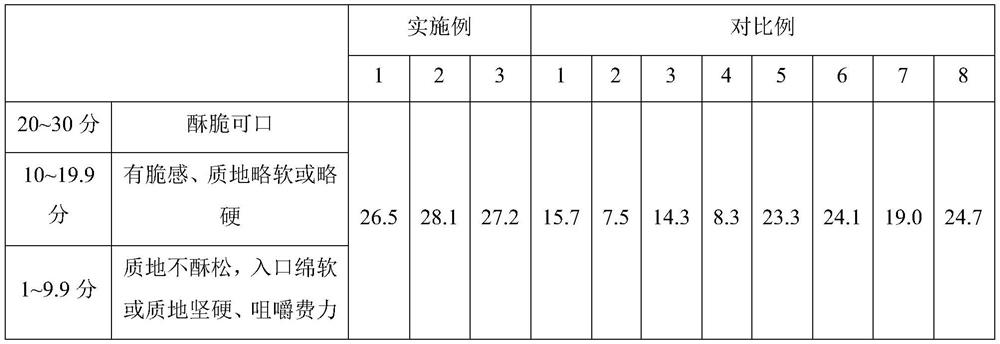

Embodiment 1

[0041] A method for improving the porous structure and texture of vacuum freeze-dried recombined mango crisps, comprising:

[0042] Step 1. Wash and remove the core of the mango, add vitamin C with a weight of 0.2% of the weight of the cored mango and citric acid with a weight of 0.05% of the weight of the cored mango to protect the color, then perform rough beating, and then add The mango skin dregs with a weight of 10% of the mango pulp weight and the pectin with a weight of 1% of the mango coarse pulp weight, and then the mango coarse pulp mixed with mango skin residues is placed in an ultrafine beater for beating once, and the beating process adopts Circulating water cooling ensures that the temperature of the pulp does not exceed 4°C until the particle size of the pulp is less than 80 μm to obtain a fine mango pulp;

[0043]Step 2: Place the mango fine pulp at 121°C to sterilize for 15 minutes, pour it into a fermenter after cooling to room temperature, then add a starter...

Embodiment 2

[0047] A method for improving the porous structure and texture of vacuum freeze-dried recombined mango crisps, comprising:

[0048] Step 1. Wash and remove the core of the mango, add vitamin C with a weight of 0.5% of the weight of the cored mango and citric acid with a weight of 0.1% of the weight of the cored mango to protect the color, then perform rough beating, and then add The mango skin dregs with a weight of 40% of the mango pulp weight and the pectin with a weight of 5% of the mango coarse pulp weight, then the mango coarse pulp mixed with mango skin residues is placed in an ultrafine beater for beating for 3 times, and the beating process adopts Circulating water cooling ensures that the temperature of the pulp does not exceed 4°C until the particle size of the pulp is less than 80 μm to obtain a fine mango pulp;

[0049] Step 2, put the mango fine pulp at 121°C to sterilize for 15 minutes, pour it into a fermenter after cooling to room temperature, then add a starte...

Embodiment 3

[0053] A method for improving the porous structure and texture of vacuum freeze-dried recombined mango crisps, comprising:

[0054] Step 1. Wash and remove the core of the mango, add vitamin C with a weight of 0.4% of the weight of the cored mango and citric acid with a weight of 0.08% of the weight of the cored mango to protect the color, then perform coarse beating, and then add The mango skin dregs with a weight of 25% of the mango pulp weight and the pectin with a weight of 3% of the mango coarse pulp weight, then the mango coarse pulp mixed with mango skin residues is placed in an ultrafine beater for beating for 2 times, and the beating process adopts Circulating water cooling ensures that the temperature of the pulp does not exceed 4°C until the particle size of the pulp is less than 80 μm to obtain a fine mango pulp;

[0055] Step 2, put the mango fine pulp at 121°C to sterilize for 15 minutes, pour it into a fermenter after cooling to room temperature, then add a star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com