Preparation method of degradable photocatalyst antibacterial mask

A photocatalyst antibacterial and mask technology, applied in the field of masks, can solve problems such as pollution, and achieve the effect of good rebound rate and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

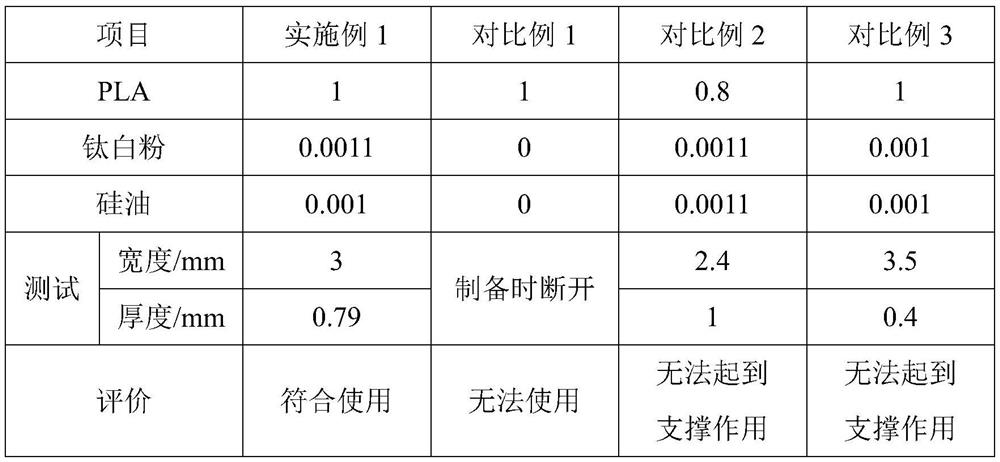

Embodiment 1

[0028] A degradable photocatalyst antibacterial mask, including a mask body and a degradable nose strip on the mask body;

[0029] The preparation method of the degradable nose strip includes the following steps: mixing polylactic acid, silicone oil, and titanium dioxide in a mass ratio of 1:0.001:0.011, and then adding them to an extruder to extrude and draw wire, and the raw materials are sequentially passed through the barrel of the extruder After heating zone 1, heating zone 2, heating zone 3, and heating zone 4 become molten, they are extruded through mold 1 zone and mold 2 zone, and finally after traction 1, traction 2 and traction 3, heating zone 1, heating zone 2. The temperatures of heating zone 3 and heating zone 4 are 130°C, 150°C, 160°C, and 170°C respectively, and the temperatures of mold 1 zone and mold 2 zone are 172°C and 175°C respectively, traction 1, traction 2 and The rotational speeds of traction 3 are 100rpm, 510rpm and 624rpm respectively.

[0030] The ...

Embodiment 2

[0033] A degradable photocatalyst antibacterial mask, including a mask body and a degradable nose strip on the mask body;

[0034] The preparation method of the degradable nose strip includes the following steps: mixing polylactic acid, silicone oil, and titanium dioxide in a mass ratio of 1:0.001:0.011, and then adding them to an extruder to extrude and draw wire, and the raw materials are sequentially passed through the barrel of the extruder After heating zone 1, heating zone 2, heating zone 3, and heating zone 4 become molten, they are extruded through mold 1 zone and mold 2 zone, and finally after traction 1, traction 2 and traction 3, heating zone 1, heating zone 2. The temperatures of heating zone 3 and heating zone 4 are 130°C, 150°C, 160°C, and 170°C respectively, and the temperatures of mold 1 zone and mold 2 zone are 172°C and 175°C respectively, traction 1, traction 2 and The rotational speeds of traction 3 are 100rpm, 510rpm and 624rpm respectively.

[0035] The ...

Embodiment 3

[0038] A degradable photocatalyst antibacterial mask, including a mask body and a degradable nose strip on the mask body;

[0039]The preparation method of the degradable nose strip includes the following steps: mixing polylactic acid, silicone oil, and titanium dioxide in a mass ratio of 1:0.001:0.011, and then adding them to an extruder to extrude and draw wire, and the raw materials are sequentially passed through the barrel of the extruder After heating zone 1, heating zone 2, heating zone 3, and heating zone 4 become molten, they are extruded through mold 1 zone and mold 2 zone, and finally after traction 1, traction 2 and traction 3, heating zone 1, heating zone 2. The temperatures of heating zone 3 and heating zone 4 are 130°C, 150°C, 160°C, and 170°C respectively, and the temperatures of mold 1 zone and mold 2 zone are 172°C and 175°C respectively, traction 1, traction 2 and The rotational speeds of traction 3 are 100rpm, 510rpm and 624rpm respectively.

[0040] The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com