Intelligent production device for high-strength flame-retardant cable PVC sheath material

A technology for flame-retardant cables and production equipment, which is applied to chemical instruments and methods, dust removal, and disperse particle filtration. It can solve problems such as pollution, impurities in raw materials, and odorous environments, so as to avoid environmental pollution and ensure collection efficiency. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

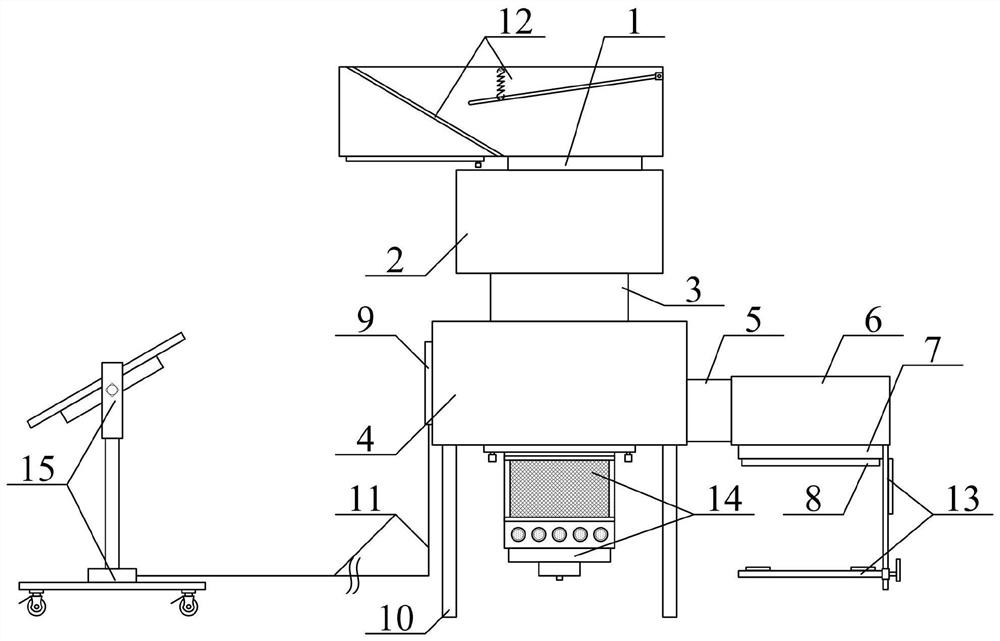

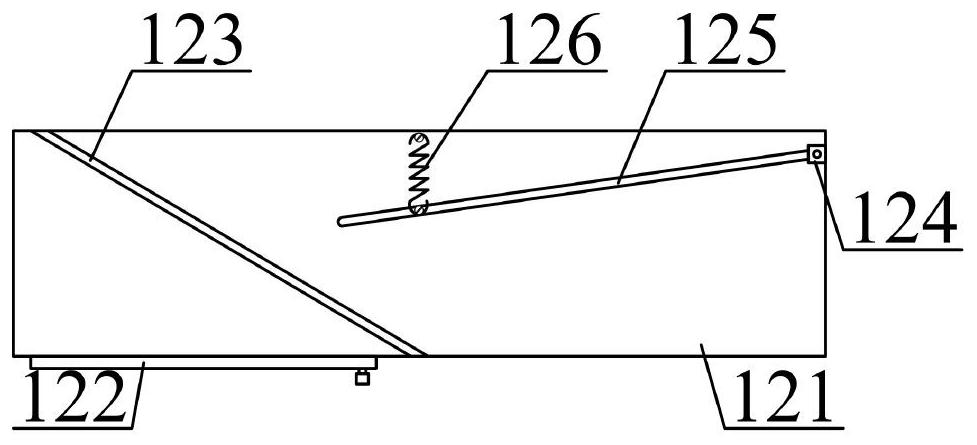

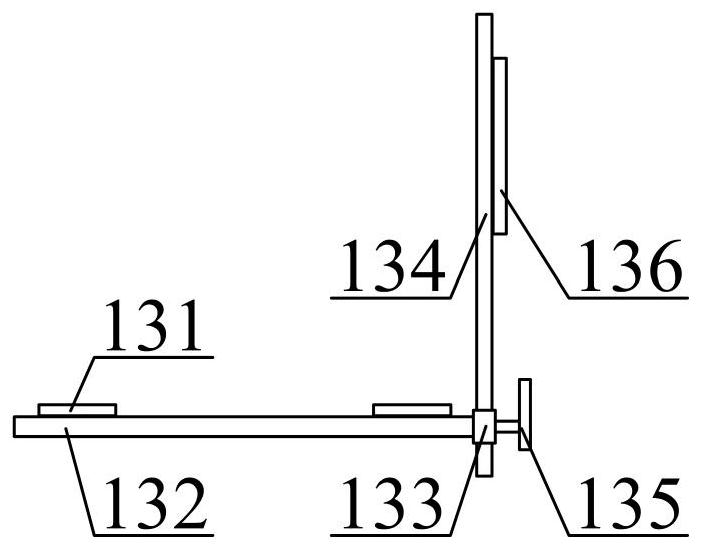

[0034] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2As shown, an intelligent high-strength flame-retardant cable PVC sheath material production device includes a feed pipe 1, a high-speed mixer 2, a diversion pipe 3, a twin-screw extruder 4, a connecting pipe 5, and screw granulation Machine 6, granulator discharge pipe 7, pellet discharge pipe 8, wiring row 9, support leg 10, cable 11, buffer type raw material filter protection bucket structure 12, adjustable weighing cable PVC sheath material collection plate structure 13 , waste gas anti-fouling adsorption treatment machine structure 14 and movable remote control panel structure 15, the feed pipe 1 is threaded at the upper entrance of the high-speed mixer 2; the guide pipe 3 is threaded at one end longitudinally At the outlet of the lower part of the high-speed mixer 2, the other end is threadedly connected to the upper inlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com