Preparation method of multi-component low-density glass bead prepreg cloth

A technology of glass microspheres and low density, applied in chemical instruments and methods, glass/slag layered products, layered products, etc., can solve the problem of inability to realize rigid support and ablation of materials, reduce mechanical properties of materials, and density of FRP materials major issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] The equipment used in the mode of this embodiment includes a dipping machine, a glue spreader, and a composite machine; the structure of the glue dipping machine mainly consists of a glue tank, a cloth threading roller, a pre-curing furnace, a winding mechanism, etc., and the structure of the glue spreader mainly includes It is composed of glue tank, extrusion roller, pre-curing furnace, winding mechanism, etc. The structure of the compound machine is mainly composed of double-layer cloth threading rollers, film-removing rollers, pressing machine, heating roller, and rewinding mechanism. Embodiment 1, the manufacture of multi-component low-density glass bead prepreg

[0083] The specific operation is:

[0084] Step 1. Selection of materials and proportions: the preparation length is 20m, and the density requirement of the multi-component low-density glass bead prepreg cloth is ≤0.75kg / m 3 ; The tensile strength requirement is ≥ 25Mpa; the calculated ratio of the amount...

Embodiment 2

[0091] Embodiment 2, the manufacture of multi-component low-density glass bead prepreg

[0092] The specific operation is:

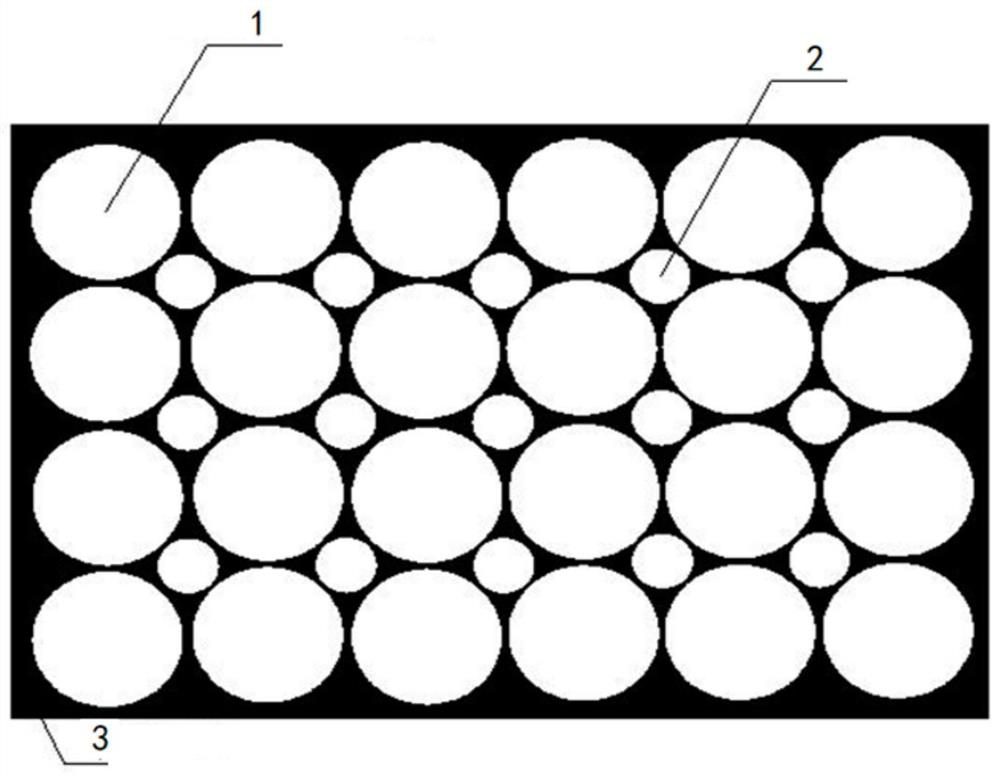

[0093] Step 1. Selection of materials and proportions: the preparation length is 50m, and the density requirement of the multi-component low-density glass bead prepreg cloth is ≤0.75kg / m 3 ; Tensile strength requirement is ≥ 25Mpa; Calculate the amount ratio of the used materials barium phenolic resin, glass fiber mesh cloth, and glass beads to be 5:4:2; Calculate the amount ratio between the large and small diameter glass beads 9:1; the model of large diameter glass beads is S20; the model of small diameter glass beads is S32;

[0094] Step 2. Heat treatment of glass fiber mesh cloth: put 12kg of glass fiber mesh cloth into the pre-curing furnace of the impregnation machine, conduct heat treatment at a temperature of 330°C, and then cool down to 90°C;

[0095] Step 3. Impregnating fiber cloth: Take 3kg of barium phenolic resin and pour it into the glu...

Embodiment 3

[0099] Embodiment 3, the manufacture of multi-component low-density glass bead prepreg

[0100] The specific operation is:

[0101] Step 1. Selection of materials and proportions: the preparation length is 20m, and the density requirement of the multi-component low-density glass bead prepreg cloth is ≤0.75kg / m 3 ; The tensile strength requirement is ≥ 25Mpa; the calculated ratio of the used materials barium phenolic resin, glass fiber mesh cloth, and glass beads is 4:3:2; calculate the amount ratio between the large and small diameter glass beads 8:1; the model of large diameter glass beads is S15; the model of small diameter glass beads is S25;

[0102] Step 2. Heat treatment of glass fiber mesh cloth: put 3kg of glass fiber mesh cloth into the pre-curing furnace of the impregnation machine, conduct heat treatment at a temperature of 350°C, and then cool down to 110°C;

[0103] Step 3. Impregnating fiber cloth: Take 0.33kg of barium phenolic resin and pour it into the glue ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com