Convenient square-bottom bag and manufacturing method thereof

A production method and technology of square bottom bags, which are applied in bag making operations, bags, sacks, etc., can solve the problems of difficult storage of bags, easy breakage and damage, and large bag size, so as to achieve convenient portability, avoid environmental pollution, and neat storage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

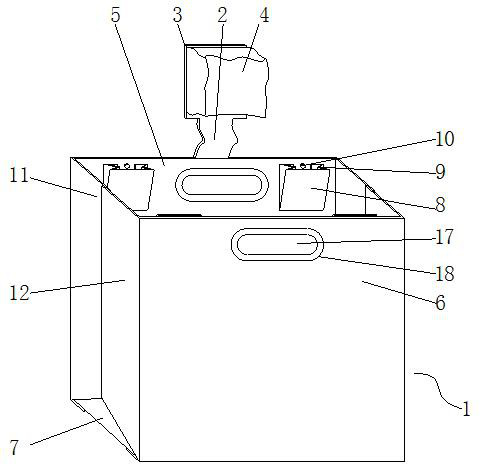

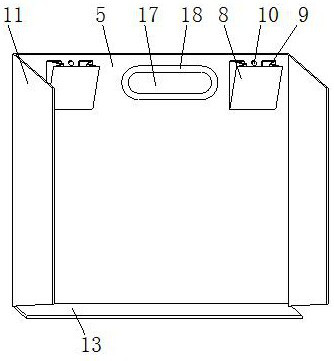

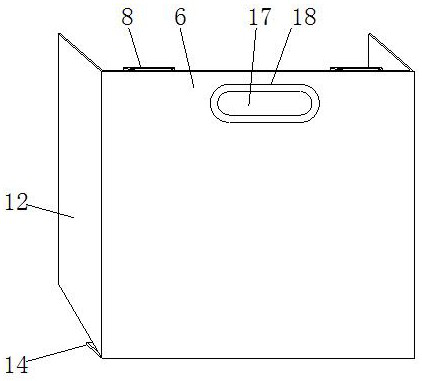

[0029] according to figure 1 , 2 , 3, 4, and 5, the present embodiment proposes a convenient square bottom bag, including a bag body 1, a connecting belt 2 and a connecting plate 3, and one side of the top of the bag body 1 is provided with a connecting belt 2, And one end of the connection belt 2 is provided with a connection plate 3, and one side of the connection plate 3 is provided with a storage bag 4, and the bag body 1 includes a first side pocket surface 5, a second side pocket surface 6 and a bottom pocket surface 7 , the first side pocket surface 5, the second side pocket surface 6, and the bottom pocket surface 7 are pasted and connected to each other, and a partition bag 8 is provided above the inside of the first side pocket surface 5 and the second side pocket surface 6, And the two sides of the separation bag 8 are corner edges 9, and above the inside of the first side pocket surface 5 and the second side pocket surface 6, an adhesive block 10 is provided, and ...

Embodiment 2

[0035] This embodiment proposes a method for making a convenient square bottom bag, comprising the following steps:

[0036] Step 1: Prepare materials: 10 parts of pulp fiber, 10 parts of cassava flour, 30 parts of chitosan, 40 parts of deionized water, 70 parts of wood fiber, 10 parts of corn starch, 2 parts of polylactic acid, 10 parts of adipic acid, 20 parts of phthalic acid, 15 parts of butanediol and 2 parts of dibenzoyl peroxide;

[0037]Step 2: Put pulp fiber, tapioca flour, chitosan, wood fiber and cornstarch into the reaction kettle, mix well at 130°C, add deionized water to dilute at the same time, then add polylactic acid, and stir at 110°C Mix to obtain the mixture, then heat and degas the mixture at 90°C for 90 minutes, then utilize a twin-screw extruder to polycondense the mixture on the extruder, the reaction temperature is 150°C, the catalyst consumption is 0.5%, and the screw speed is 75 r / min, obtain the first base material;

[0038] Step 3: Esterify adipi...

Embodiment 3

[0044] This embodiment proposes a method for making a convenient square bottom bag, comprising the following steps:

[0045] Step 1: Prepare materials: 15 parts of pulp fiber, 15 parts of cassava flour, 40 parts of chitosan, 45 parts of deionized water, 100 parts of wood fiber, 30 parts of corn starch, 2 parts of polylactic acid, 15 parts of adipic acid, 30 parts of phthalic acid, 20 parts of butanediol and 2 parts of dibenzoyl peroxide;

[0046] Step 2: Put pulp fiber, tapioca flour, chitosan, wood fiber and cornstarch into the reaction kettle, mix well at 130°C, add deionized water to dilute at the same time, then add polylactic acid, and stir at 110°C Mix to obtain the mixture, then heat and degas the mixture at 90°C for 90 minutes, then utilize a twin-screw extruder to polycondense the mixture on the extruder, the reaction temperature is 150°C, the catalyst consumption is 0.5%, and the screw speed is 75 r / min, obtain the first base material;

[0047] Step 3: Esterify adi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com