Preparation method of graphene heating coating and preparation method of heating sheet

A heating coating and graphene technology, applied in conductive coatings, heating element materials, epoxy resin coatings, etc., can solve the problems of inability of constant temperature and power compensation of heating elements, complex structure of electric heating system, and low resistance value of nickel-chromium alloys, etc. To achieve the effect of rich raw materials, high heating temperature, heat accumulation and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] A preparation method for graphene heat-generating coating, is characterized in that, comprises the following steps:

[0047] Step 1: Prepare 2.5g of graphene, 2.5g of epoxy resin, 10g of dispersant, 73g of ethanol and 2g of metal neodymium powder;

[0048] Step 2: Mix the graphene with the disperser, adjust the power of the grinder to 300W, control the grinder to work for 5 hours, and grind and disperse;

[0049] Step 3: After the grinding in step 2, continue to add metal neodymium powder, control the grinder to work for 2 hours, and grind and disperse;

[0050] Step 4: After the grinding in step 3, continue to add epoxy resin, control the grinder to work for 3 hours, and grind and disperse;

[0051] Step 5: After the grinding in step 4, continue to add ethanol, control the grinder to work for 1 minute, and grind and disperse to form a graphene heating coating solution.

[0052] Further, the formula ratio of the graphene heating coating solution is as follows:

[005...

Embodiment

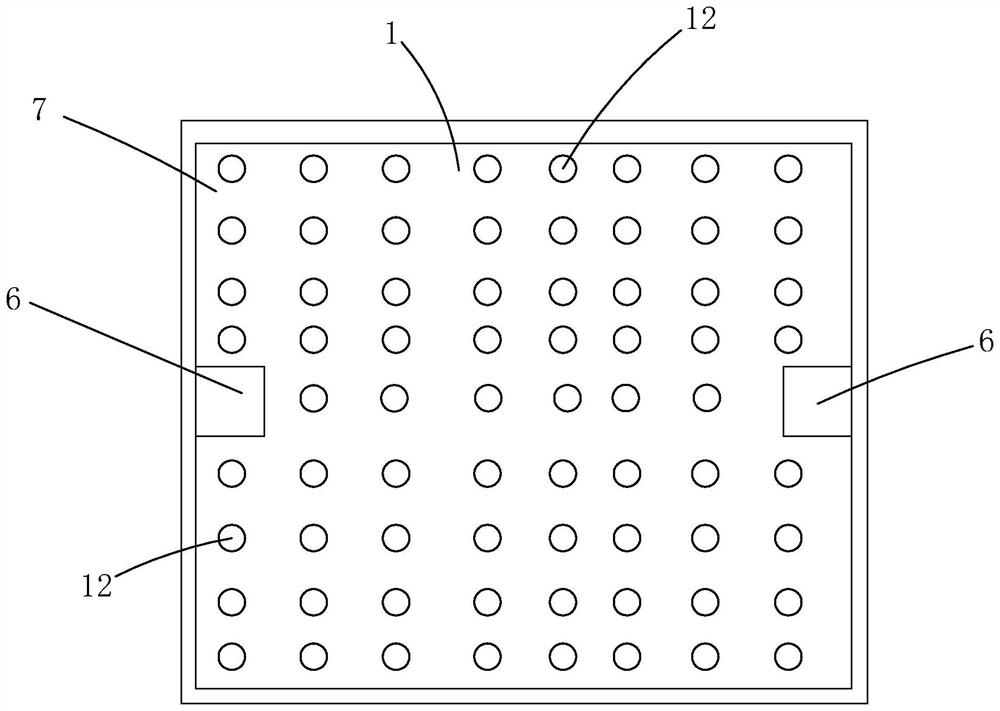

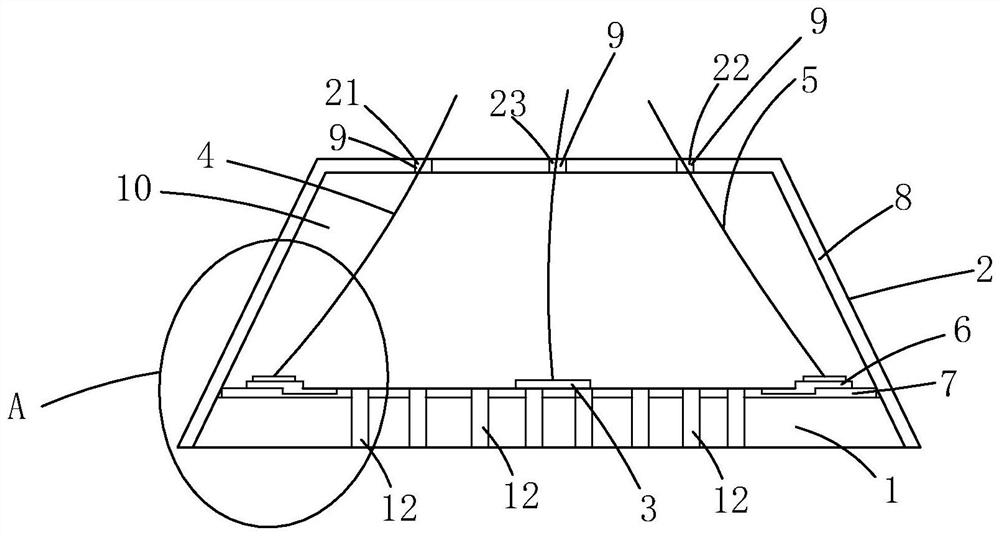

[0070] Example, combined with figure 1 Shown, a kind of heating chip comprises ceramic panel 1, and described ceramic panel 1 is spaced apart with through hole 12, and one end surface of ceramic panel 1 is sprayed with conductive coating 6, and the graphene of 2.5um thickness is sprayed on ceramic panel 1 to generate heat The coating forms a graphene heating coating 7, and the graphene heating coating 7 covers a part of the conductive coating 6, and a part of the conductive coating 6 is exposed outside the graphene heating coating 7.

[0071] The ceramic panel 1 is spaced with through holes 12 to enhance the heat conduction effect of the ceramic panel 1, make the ceramic panel 1 heat up more quickly, increase the heating temperature, and meet user needs.

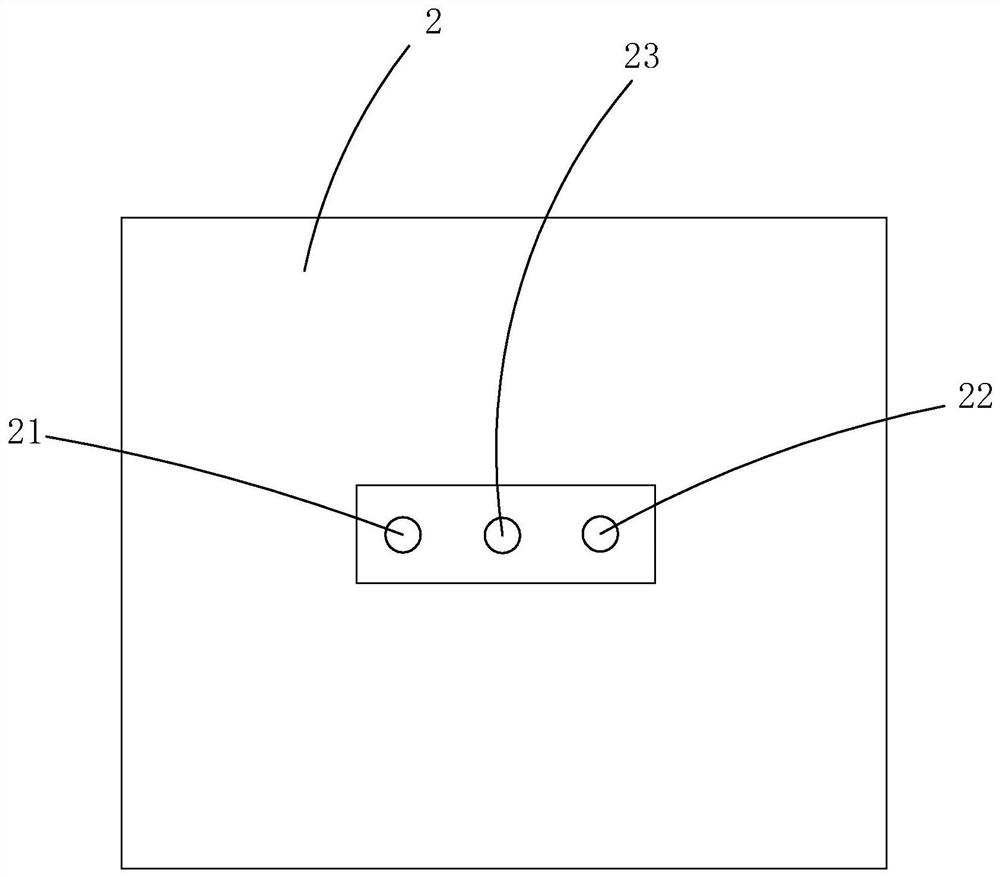

[0072] Example, combined with Figure 2 to Figure 5 As shown, a heating brick for a blister machine includes a ceramic panel 1 , a ceramic cover 2 , a temperature sensor 3 , a live wire 4 and a neutral wire 5 .

[0073] Bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com