A kind of tasteless eyelashes grafting glue and preparation method and application thereof

An eyelash and odorless technology, applied in the field of odorless eyelash grafting glue and its preparation, can solve the problems of hindering the popularization and use of eyelash grafting glue, complex production process, short shelf life, etc. The effect of whitening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

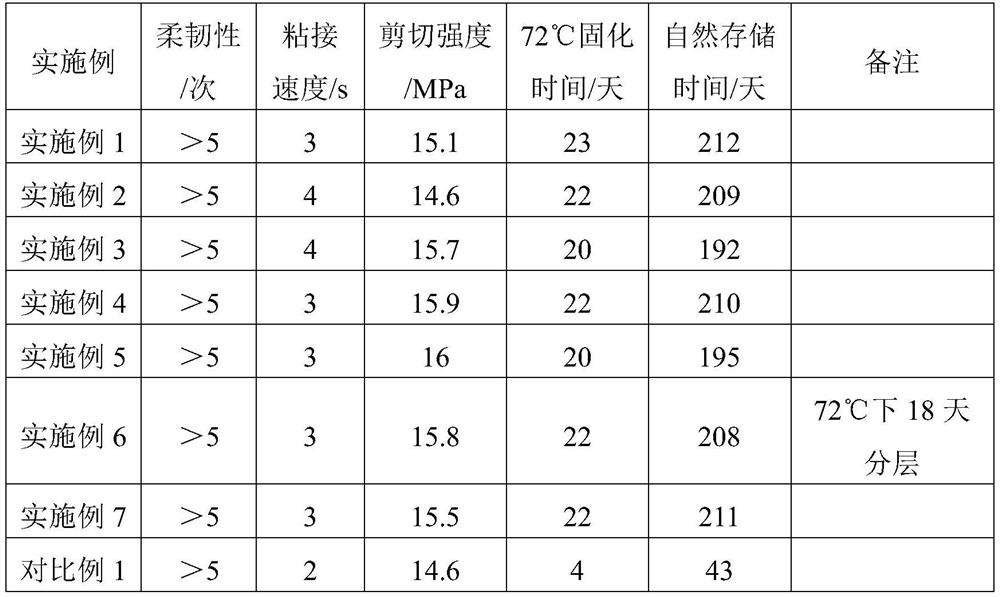

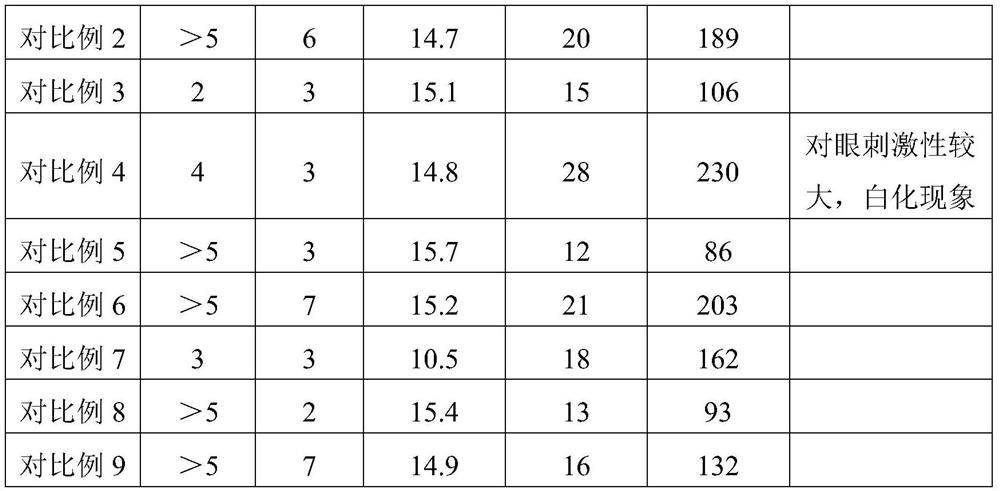

Examples

Embodiment 1

[0034] An odorless eyelash grafting glue, comprising the following raw material composition by mass percentage: 91.85% of α-methoxyethyl cyanoacrylate, 5% of ethylene acrylate rubber, 3% of AS type black masterbatch, and polyethylene glycol 600 diacrylate 0.15%.

[0035] The preparation method of above-mentioned tasteless eyelash grafting glue, comprises the steps as follows:

[0036] At room temperature, add α-methoxyethyl cyanoacrylate into the three-necked flask, under stirring conditions, add polyethylene glycol 600 diacrylate and AS type black masterbatch, stir evenly at room temperature, and then add ethylene acrylate rubber , dissolved at room temperature and then stirred for 0.5 h to obtain an odorless eyelash grafting glue.

Embodiment 2

[0038] An odorless eyelash grafting glue, comprising the following raw material composition by mass percentage: 91.85% of α-cyanoacrylate ethoxyethyl ester, 5% of ethylene acrylate rubber, 3% of AS type black masterbatch, and polyethylene glycol 600 diacrylate 0.15%.

[0039] The preparation method of above-mentioned tasteless eyelash grafting glue, comprises the steps as follows:

[0040] At room temperature, add α-cyanoacrylate ethoxyethyl into the three-necked flask, under stirring conditions, add polyethylene glycol 600 diacrylate and AS type black masterbatch, stir evenly at room temperature, and then add ethylene acrylate rubber , dissolved at room temperature and then stirred for 0.5 h to obtain an odorless eyelash grafting glue.

Embodiment 3

[0042] An odorless eyelash grafting glue, comprising the following raw material composition by mass percentage: 91.85% of n-butyl α-cyanoacrylate, 5% of ethylene acrylate rubber, 3% of AS type black masterbatch, and 0.15% of polyethylene glycol 600 diacrylate .

[0043] The preparation method of above-mentioned tasteless eyelash grafting glue, comprises the steps as follows:

[0044] At room temperature, add α-butyl cyanoacrylate into the three-necked flask, under stirring conditions, add polyethylene glycol 600 diacrylate and AS type black masterbatch, stir evenly at room temperature, then add ethylene acrylate rubber, room temperature After dissolving, it is stirred for 0.5 h to obtain an odorless eyelash grafting glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com