A precipitation-strengthened nickel-cobalt-based alloy with high oxidation resistance and its preparation method

A nickel-cobalt-based alloy, precipitation strengthening technology, applied in the direction of manufacturing tools, furnace types, heat treatment equipment, etc., can solve the problems of alloy plasticity, reduction of hot workability welding performance, increase of alloy precipitation tendency, low high temperature strength, etc., to avoid Mechanical properties, the effect of increasing the adjustment margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the precipitation-strengthened nickel-cobalt-based alloy with high oxidation resistance comprises the following steps:

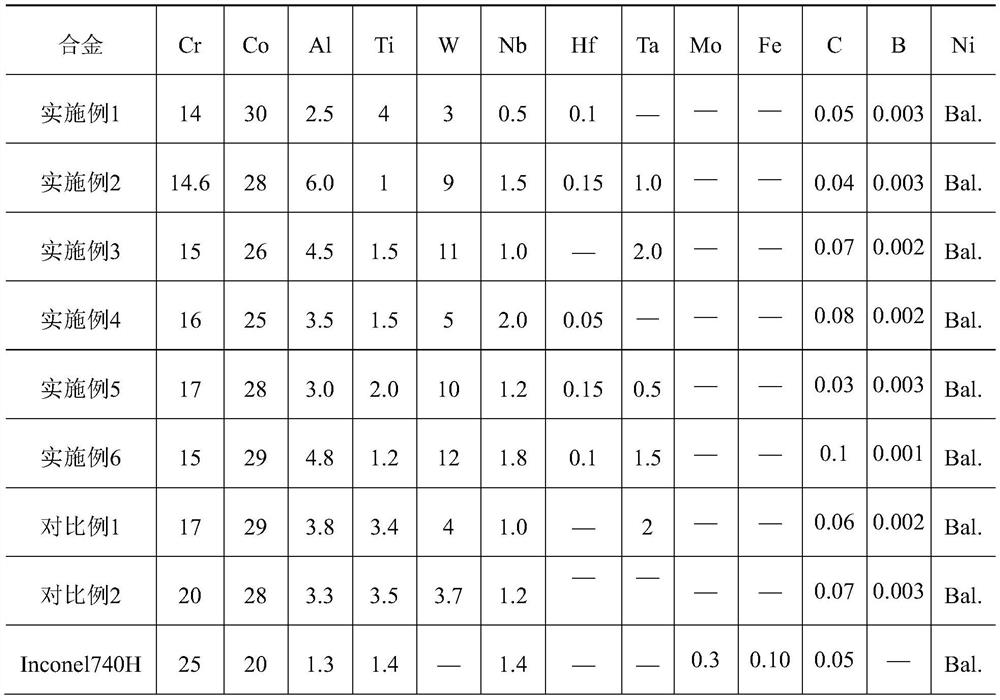

[0029] (1) Alloy smelting: elements by mass fraction, 0.03≤C≤0.1%, 0<B≤0.003%, 14≤Cr≤17%, 25≤Co≤30%, 3≤W≤12%, 0.5≤ Nb≤2%, 2.5≤Al≤6%, 1≤Ti≤4%, 0≤Hf≤0.15%, 0≤Ta≤2%, the balance is Ni,

[0030] Among them, when 1.5≤Al / Ti≤3, 42 The formation of the promoted continuous Al 2 o 3 film formation.

[0031] According to the above-mentioned chemical composition ratio, the alloy raw material is put into a vacuum induction arc furnace, melted and refined to obtain an alloy ingot.

[0032] (2) Homogenization treatment: Homogenize the alloy ingot at 10-30° C. above the solid solution temperature of the γ′ phase for 24-72 hours, and then air-cool to room temperature.

[0033] (3) Rolling: the homogenized alloy ingot is rolled at a temperature of 30-50°C above the solid solution temperature of the γ′ phase;

[0034] (4) Heat treatment: h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com