Preparation method and application of a waterproof and heat-insulating coating agent

A technology of thermal insulation coating and solvent, applied in textiles and papermaking, etc., can solve the problems of increasing the thickness and weight of fabrics, human discomfort, temperature difference of thermal insulation effect, etc., to prevent discomfort, simple preparation method, and increase thermal insulation rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

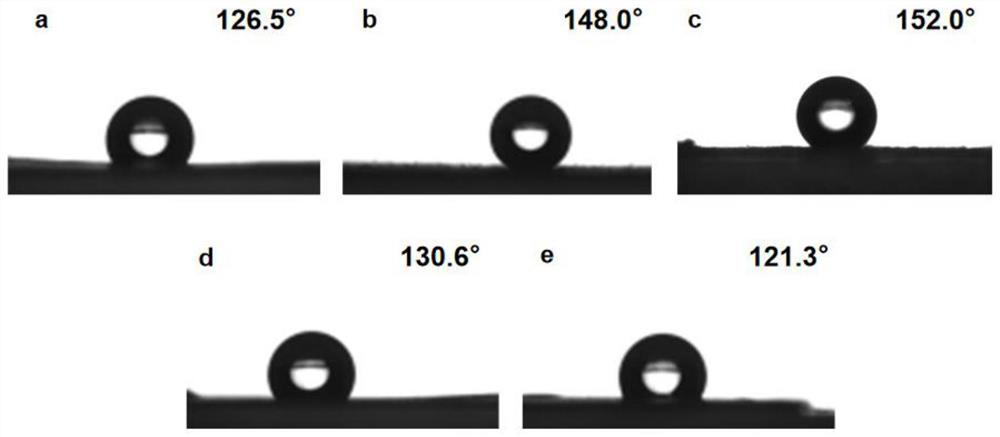

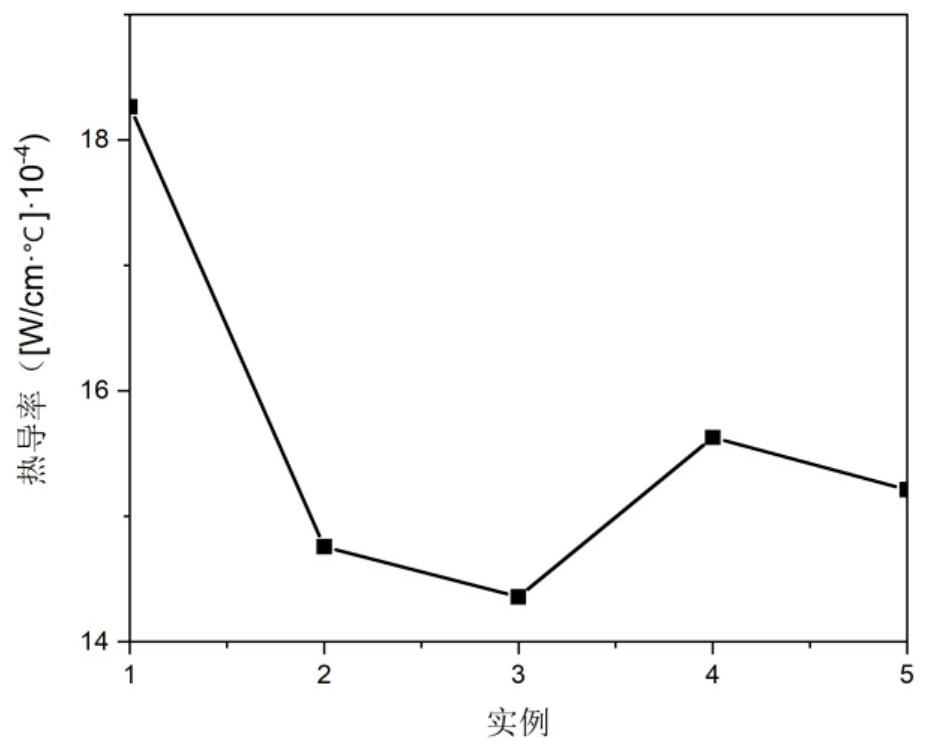

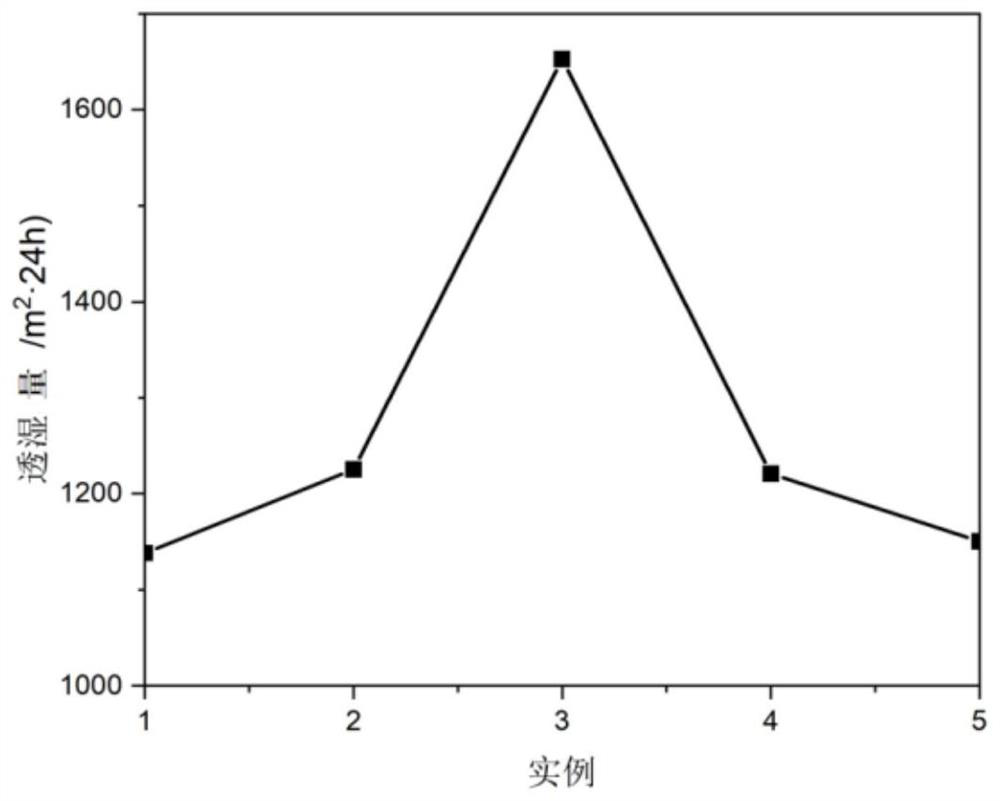

Embodiment 1

[0032] This embodiment provides a method for preparing a waterproof and heat-insulating coated textile, comprising the following steps:

[0033] (1) Dissolve 7g of PVDF-HFP powder in 17g of acetone, stir at 60°C at a speed of 300r / min for 40min, and fully dissolve to a clear and transparent PVDF-HFP solution.

[0034] (2) 6 g of water and 34 g of acetone were magnetically stirred and mixed uniformly to obtain a water / acetone mixture.

[0035] (3) Slowly add the water / acetone mixture obtained in step (2) dropwise into the PVDF-HFP solution that is being heated and stirred in step (1) and has been fully dissolved, and continue to maintain the temperature at 60°C at a speed of 300r / min Stir for 20 min to obtain post-treatment liquid.

[0036] (4) the hydrophobic SiO of 2wt% of aftertreatment liquid in step (3) 2 The airgel particles are added to the post-treatment solution obtained in step (3), and ultrasonically dispersed for 20 minutes to obtain a waterproof and heat-insulati...

Embodiment 2

[0039] This embodiment provides a method for preparing a waterproof and heat-insulating coated textile, comprising the following steps:

[0040] (1) Dissolve 3g of PVDF-HFP powder in 20g of acetone, stir at 40°C at a speed of 300r / min for 20min, and fully dissolve to a clear and transparent PVDF-HFP solution.

[0041] (2) 2 g of water and 10 g of acetone were magnetically stirred and mixed uniformly to obtain a water / acetone mixture.

[0042] (3) Slowly add the water / acetone mixture obtained in step (2) dropwise into the PVDF-HFP solution that is being heated and stirred in step (1) and has been fully dissolved, and continue to maintain at 40°C at a speed of 300r / min Stir for 40 min to obtain the post-treatment liquid.

[0043] (4) the hydrophobic SiO of 3wt% of aftertreatment liquid in step (3) 2 The airgel particles are added to the post-treatment liquid obtained in step (3), and ultrasonically dispersed for 15 minutes to obtain a waterproof and heat-insulating coating age...

Embodiment 3

[0046] This embodiment provides a method for preparing a waterproof and heat-insulating coated textile, comprising the following steps:

[0047] (1) Dissolve 5g of PVDF-HFP powder in 20g of acetone, stir at 50°C at a speed of 300r / min for 30min, and fully dissolve to a clear and transparent PVDF-HFP solution.

[0048] (2) 4 g of water and 21 g of acetone were magnetically stirred and mixed uniformly to obtain a water / acetone mixture.

[0049] (3) Slowly add the water / acetone mixture obtained in step (2) dropwise into the PVDF-HFP solution that is being heated and stirred in step (1) and has been fully dissolved, and continue to maintain the speed of 300r / min at 50°C Stir for 30 min to obtain post-treatment liquid.

[0050] (4) the hydrophobic SiO of 4wt% of aftertreatment liquid in step (3) 2 The airgel particles are added to the post-treatment solution obtained in step (3), and ultrasonically dispersed for 10 minutes to obtain a waterproof and heat-insulating coating agent. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com