Photoelectric detector and preparation method thereof

A photodetector and electrode technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of increased dark current of detectors, large coupling loss of direct coupling, etc., to achieve large response bandwidth, improve performance, and improve coupling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

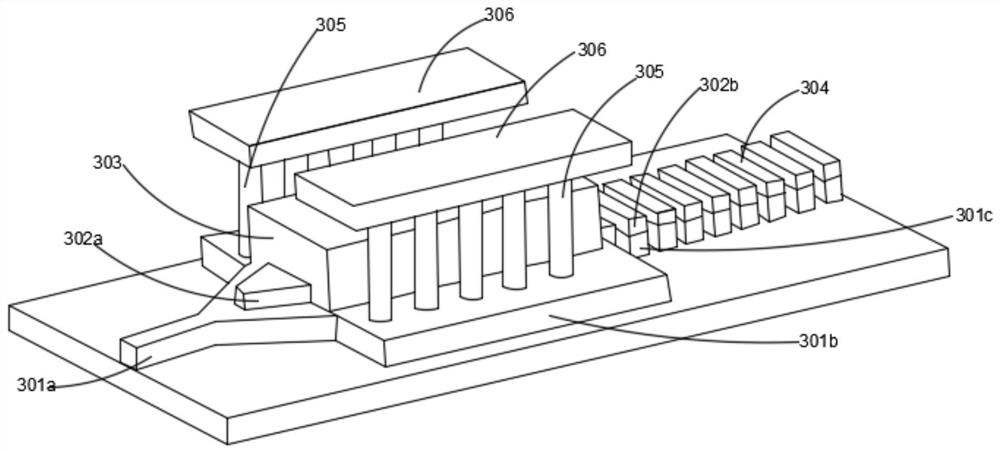

[0051] Such as image 3 Horizontal photodetectors shown, including:

[0052] SOI substrate, one end of the top layer of silicon forms a pyramid-shaped silicon waveguide 301a, and the opposite end forms a Bragg grating array 304, and each grating in the array is formed by stacking top-layer silicon 301c and polysilicon 302b from bottom to top; the pyramid-shaped silicon waveguide 301a has a first end and a second end, the area of the first end being smaller than the area of the second end.

[0053] The upper surface of the silicon waveguide 301a close to the first end is covered with a pyramid-shaped polysilicon 302a, and the polysilicon 302a is used to buffer the coupling of the silicon waveguide 301a to the germanium layer 303 .

[0054] The upper surface of the silicon waveguide 301a close to the second end is covered with a germanium layer 303, and the germanium layer 303 is spliced together with the aforementioned polysilicon 302a.

[0055] A P-doped region 301b an...

Embodiment 2

[0068] Utilize the method similar to embodiment 1 to make vertical type photodetector, structure such as Figure 12 As shown (cross-sectional view along the waveguide direction), the difference between the two manufacturing methods is that the implanted ion regions are different (the N-doped region 401 is arranged on the top-layer silicon, the silicon waveguide is still located on the top-layer silicon, and the P-doped region 403a is arranged on the germanium layer. 403 , the positions of the N-doped region and the P-doped region can also be exchanged in practical applications), and the position of the contact hole 404 changes accordingly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com