Method for purifying terephthalylidene dicamphor sulfonic acid

A technology of terephthalimethylene dicamphorsulfonic acid and terephthalene dicamphor sulfonic acid is applied in the field of purification methods related to terephthalimethylene dicamphor sulfonic acid, and can solve the problem of lowering the content, Inability to remove anionic substances such as chlorine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

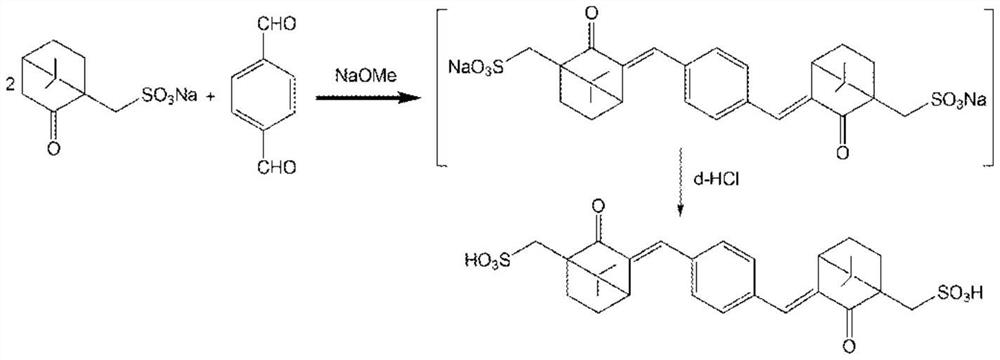

[0071] Step 1: Synthesis of Terexylylene Dicamphorsulfonic Acid

[0072] After dispersing 223 g of sodium methoxide and 464.8 g of 10-d,l-camphorsulfonic acid in 4 liters of toluene and 0.2 liter of methanol, 134.2 g of terephthalaldehyde was added and reacted in a nitrogen atmosphere. Hydrochloric acid and water were added and heated, and after refluxing, toluene was removed and cooled. This was filtered and dried to obtain 428.0 g of terexylylenebiscamphorsulfonic acid. This is the substance before purification obtained by acid neutralization after synthesis.

[0073] Step 2: the purification of terexylylene biscamphorsulfonic acid

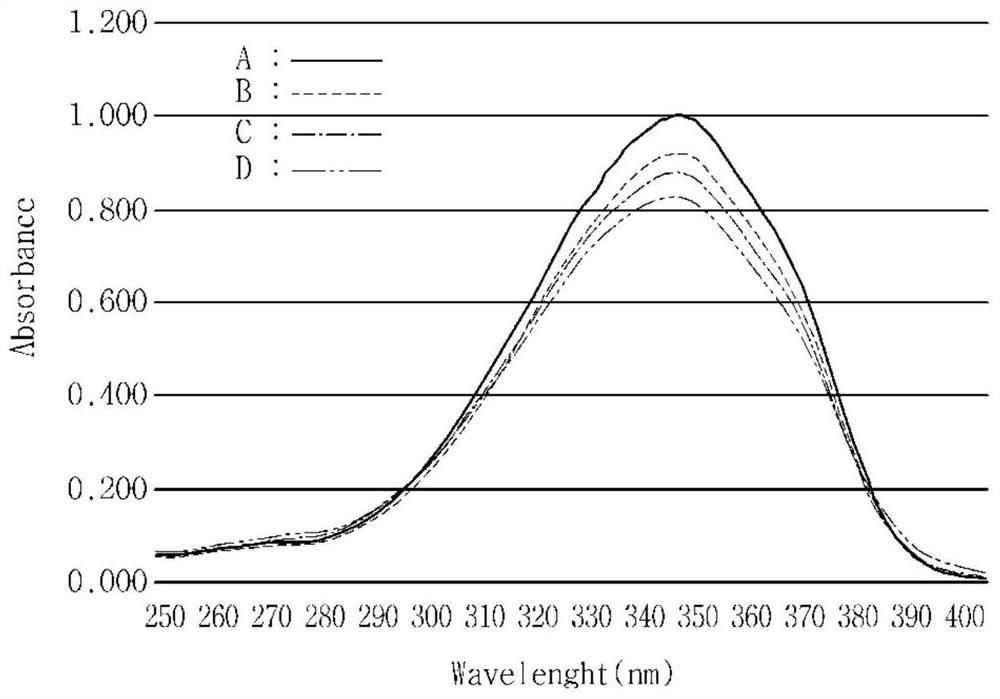

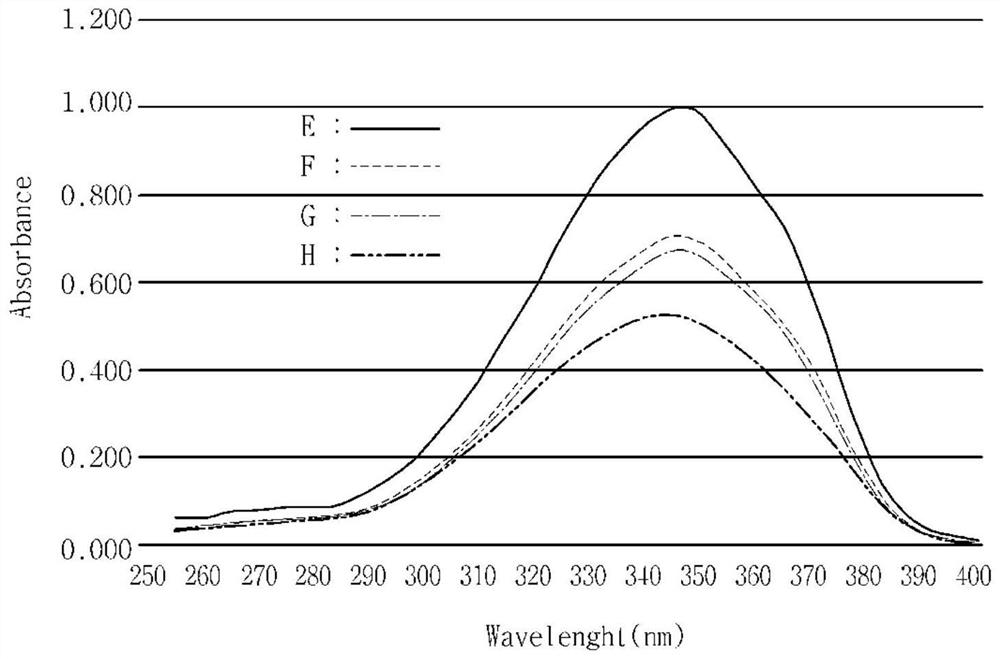

[0074] After dissolving 100 g of terexylylenebiscamphorsulfonic acid obtained in step 1 in 2,000 ml of purified water, it was slowly passed through activated 1,300 ml of Samyang Corporation UPRC320 cation exchange resin for 1 hour After mixing and filling the column with 200ml of Samyang Corporation UPRA320 anion exchange resin, the aqueous s...

Embodiment 2

[0076] After putting 100 g of terephthalylidene biscamphorsulfonic acid obtained in Step 1 of said Example 1 into 2,000 ml of purified water, it was slowly passed through 1,125 ml of activated Samyang Co. After the column was mixed and filled with UPRC320 cation exchange resin and 375ml Samyang Corporation UPRA320 anion exchange resin, the accumulated aqueous solution of terexylylenebiscamphorsulfonic acid was removed under high vacuum by washing with 1,000ml of purified water. After concentrating with water, 300 ml of acetone was added to precipitate, and after filtration, it was dried to obtain 80 g of the target substance.

Embodiment 3

[0078] After dissolving 100 g of terephthalylidene biscamphorsulfonic acid obtained in Step 1 of said Example 1 in 2,000 ml of purified water, it was slowly passed through 1,425 ml of activated Samyang Co. UPRC320 cation exchange resin and 75ml of Samyang Corporation UPRA320 anion exchange resin were mixed and packed, after that, the accumulated aqueous solution of terephthalylidene dicamphorsulfonic acid was removed under high vacuum by washing with 1,000ml of purified water After concentration with purified water, 300 ml of acetone was added to precipitate, filtered, and then dried to obtain 88.3 g of the target product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com