Centrifugal filter

A centrifugal and filter technology, applied in the field of filters, can solve the problems of difficult-to-filter cloth forming filter cake, suitable filter type centrifuges, self-weight and other problems, and achieve the effect of improving filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

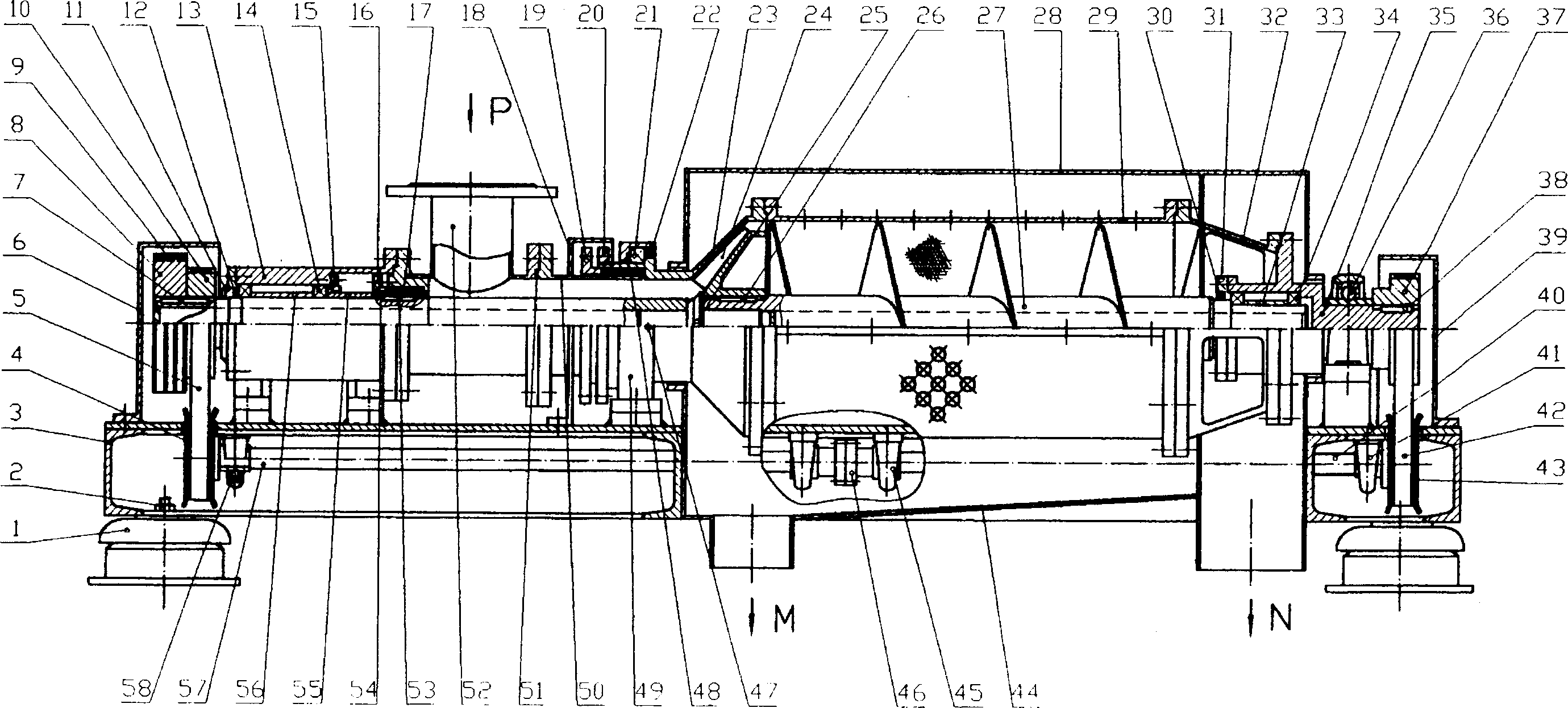

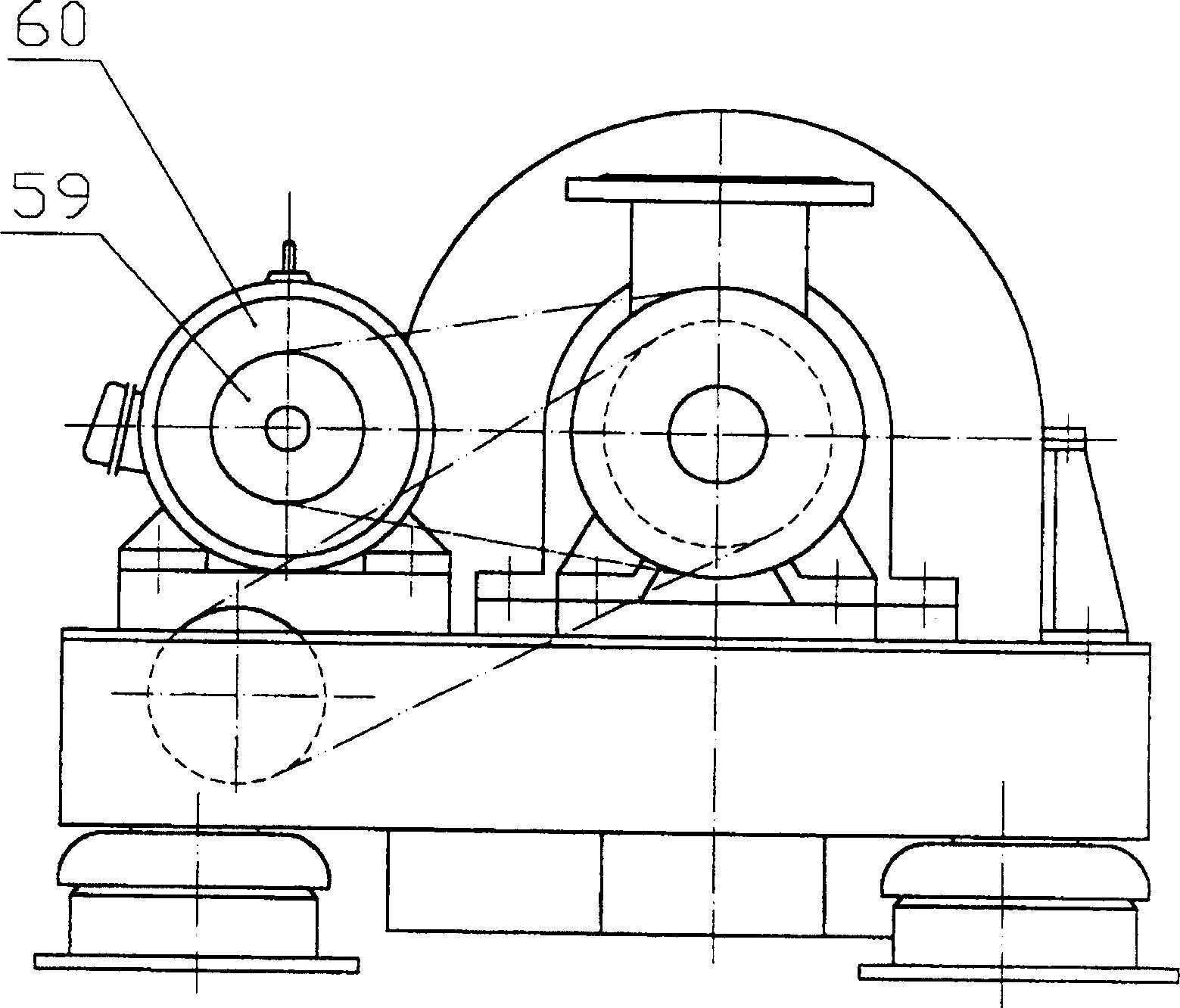

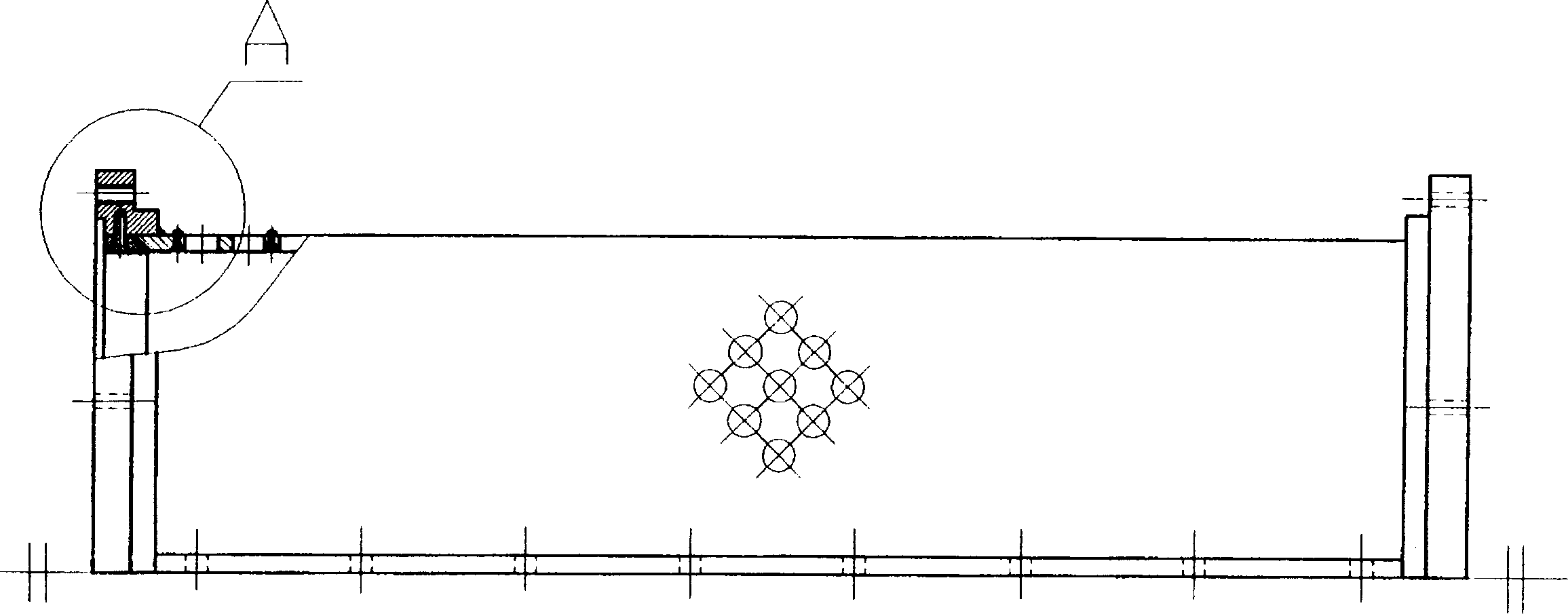

[0029] refer to figure 1 , figure 2 , the present invention includes a base 3 and various shells and supporting bases fixedly connected with the base 3 . Described housing can be divided into upper machine cover 28, lower machine cover 44, and cover shell 6 and cover shell 18, and described support seat can be divided into front bearing seat 13, middle bearing seat 49, belt seat bearing 36, front belt Seat bearing 58, middle band seat bearing 45, rear band seat bearing 41.

[0030] Put a screw shaft 27 in upper and lower machine cover 28,44, this screw shaft 27 maximum diameter φ 121 (small φ 61 of inner hole diameter), has screw blade on the screw shaft 27. One end of screw shaft 27 is connected with front axle 25, and this front axle 25 is connected with base 3 by two bearings 14, front bearing block 13, and the other end is rotationally connected with rear axle 35 by two bearings 34, and is connected by belt seat Bearing 36 supports. The front end of the front axle 25 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com