Continuous production device and manufacturing process of arc-striking-preventing alloy copper

A technology of production equipment and manufacturing process, which is applied in the field of continuous production equipment for anti-arc alloy copper, can solve the problems of inability to realize continuous production, low yield, and low efficiency, and improve product quality and production efficiency. Granular refinement, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

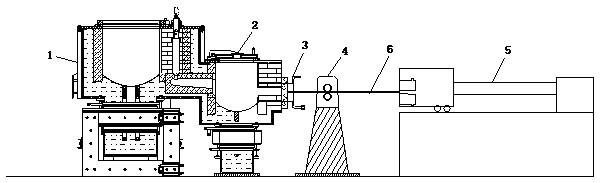

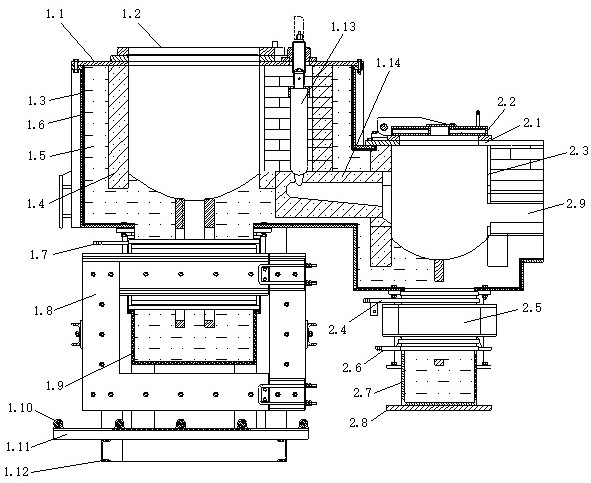

[0031] see Figure 1~Figure 4 , a continuous production device for arc-proof alloy copper, comprising a melting furnace 1, a holding furnace 2, an electromagnetic stirring device 3, a continuous extruder 4 and a drawing machine 5 arranged in sequence, and the melting furnace 1 and the holding furnace 2 are composed Horizontal smelting unit.

[0032] The melting furnace 1 includes a melting furnace body 1.3, a melting furnace upper cover 1.1 is arranged above the melting furnace body 1.3, and a melting furnace cover 1.2 that can be opened in half is provided on the melting furnace upper cover 1.1. A refractory brick 1.4 is arranged inside the body 1.3, and the refractory brick 1.4 forms an accommodating cavity, and a charge 1.5 is arranged between the refractory brick 1.4 and the inner wall of the melting furnace body 1.3, and a layer of refractory insulation felt is also provided on the inner wall of the melting furnace body 1.3 1.6;

[0033] A melting furnace water jacket 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap