Iron-based-ferrite material, preparation method and application thereof

A ferrite material and ferrite technology, applied in the field of materials, can solve the problems of landing, dust accumulation, strong water absorption, etc., and achieve the effects of not easy to diffuse and float, light pollution, and strong water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

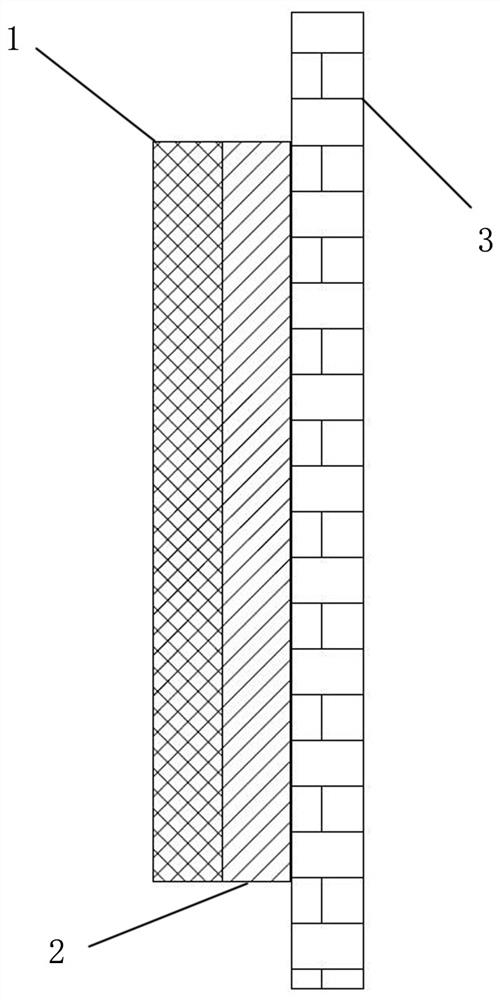

Image

Examples

Embodiment 1

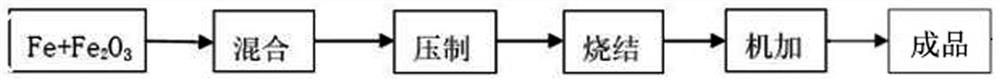

[0038] A method for preparing an iron-based-ferrite friction plate comprises the following steps.

[0039] (1) Add 1% zinc stearate of the iron-based-ferrite material into the iron-based-ferrite material, and mix uniformly to obtain a powder.

[0040] (2) Load the powder into the steel mold for pressing and forming, at 4-5 tons of force / cm 2 Squeeze and demould under pressure to form compacts; take qualified compacts and put them into a continuous sintering furnace for sintering, the heating rate is 50-100°C / h, the sintering temperature is 1100°C, and the heat preservation is 3h. During the process, N 2 for protection.

[0041] (3) After sintering, an iron-based-ferrite friction plate is obtained.

[0042] The iron-based-ferrite material is composed of 40% pure iron powder and 60% strontium ferrite.

Embodiment 2

[0044] A method for preparing an iron-based-ferrite friction plate comprises the following steps.

[0045] (1) Add 1% polyvinyl alcohol of the iron-based-ferrite material into the iron-based-ferrite material, and mix evenly to obtain a powder.

[0046] (2) Load the powder into the steel mold for pressing and forming, at 4-5 tons of force / cm 2 Squeeze and demould under pressure to form compacts; take qualified compacts and put them into a continuous sintering furnace for sintering, the heating rate is 50-100°C / h, the sintering temperature is 1130°C, and the heat preservation is 4h. During the process, N 2 for protection.

[0047] (3) After sintering, an iron-based-ferrite friction plate is obtained.

[0048] The iron-based-ferrite material consists of 43% pure iron powder and 57% strontium ferrite.

Embodiment 3

[0050] A method for preparing an iron-based-ferrite friction plate comprises the following steps.

[0051] (1) Add 1% polyvinyl alcohol of the iron-based-ferrite material into the iron-based-ferrite material, and mix evenly to obtain a powder.

[0052] (2) Load the powder into the steel mold for pressing and forming, at 4-5 tons of force / cm 2 Squeeze and demould under pressure to form compacts; take qualified compacts and put them into a continuous sintering furnace for sintering, the heating rate is 50-100°C / h, the sintering temperature is 1130°C, and the heat preservation is 4h. During the process, N 2 for protection.

[0053] (3) After sintering, an iron-based-ferrite friction plate is obtained.

[0054]The iron-based-ferrite material is composed of 45% pure iron powder and 55% strontium ferrite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com