Series conical bearing outer ring one-piece flow lathing process

A tapered bearing and lathe processing technology, which is applied in the field of one-piece flow lathe processing of the outer ring of a series of tapered bearings, can solve the problems of high personal labor intensity, limited chuck adjustment range, and easy work-related injuries, so as to improve product quality and Production efficiency, prevention of missing processes, and shortening of adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

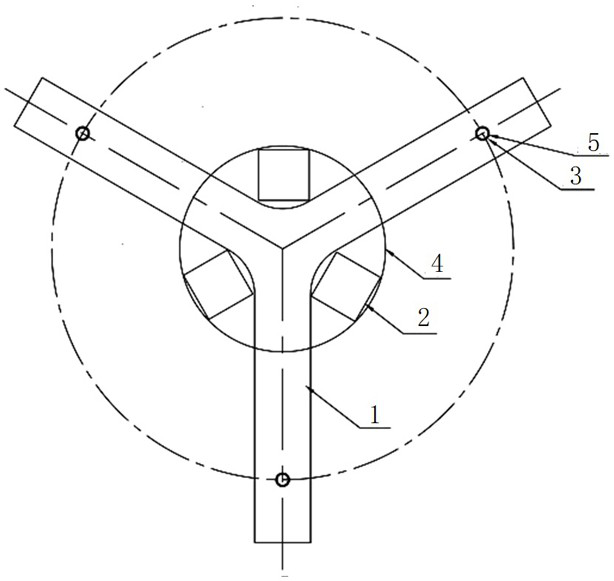

[0038] The present invention processes the tapered bearing outer ring with an inner diameter of φ120-150MM in one-piece flow processing as follows:

[0039] Select the clamping claw 7 that is consistent with the shape and height of the chamfering part of the outer ring of the tapered bearing within the inner diameter range of 120-150mm, and install it on the base body, and install the pop-up rod 9 on the outermost guide hole 8; the process includes:

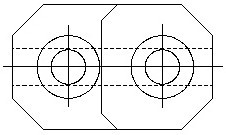

[0040] (1) Manually place the blank forgings of the outer ring of the tapered bearing with an outer diameter of φ160-200MM, a height of 35-50MM, and an inner diameter of φ120-150MM on the feeding tray of the rotary material warehouse, and are clamped by two sets of clamping system ejection mechanisms. After the outer ring blank forgings are finished, they are sent to the first CNC lathe, and one of the outer ring blank forgings is clamped;

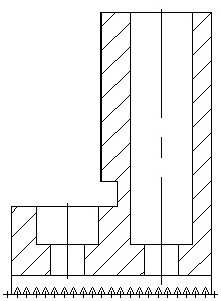

[0041] (2) First sequence: the first CNC lathe completes the car raceway, car inner chamf...

Embodiment 2

[0046] The present invention processes the tapered bearing outer ring with an inner diameter of φ80 to 120MM in one-piece flow processing as follows:

[0047] Select the clamping claw 7 that is consistent with the shape and height of the chamfering part of the outer ring of the tapered bearing within the inner diameter range of 80-120mm and install it on the base body, and the pop-up rod 9 is installed on the innermost guide hole 8; the process is only the first (1 ) step process is different from embodiment 1, and the (1) step process of embodiment 2 comprises:

[0048] (1) Manually place the blank forgings of the outer ring of the tapered bearing with an outer diameter of φ100-160MM, a height of 20-35MM and an inner diameter of φ80-120MM on the feeding tray of the rotary material warehouse, and are clamped by two sets of clamping system ejection mechanisms respectively. After the outer ring blank forgings are finished, they are sent to the first CNC lathe, and one of the out...

Embodiment 3

[0050] The process of processing the outer ring of the tapered bearing with an inner diameter of φ20-80MM in the present invention is as follows:

[0051] Select the clamping claw 7 that is consistent with the shape and height of the chamfer of the outer ring of the tapered bearing within the inner diameter range of 20 to 80mm and install it on the base, and the pop-up rod 9 is installed on the innermost guide hole 8; the process described is only the first (1 ) step process is different from embodiment 1, and the (1) step process of embodiment 3 comprises:

[0052] (1) Manually place the blank forgings of the outer ring of the tapered bearing with an outer diameter of φ40-100MM, a height of 10-20MM and an inner diameter of φ20-80MM on the feeding tray of the rotary material warehouse, and one piece is clamped by two sets of clamping system ejection mechanisms After the outer ring blank forging is sent to the first CNC lathe, one of the outer ring blank forgings is clamped.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter φ | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Inner diameter φ | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com