Water treatment denitrification filler and preparation method thereof

A technology for water treatment and denitrification, applied in water treatment parameter control, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of unfavorable microbial film formation and stability, affecting reaction effect, limited adsorption capacity, etc. problems, to achieve the effects of stable and long-lasting biological denitrification performance, improved removal rate, and developed porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of filler A: prepare oxalic acid solution of 20g / L; uniformly grind pyrite and sulfur into fine powder with a particle size of 5-10nm, and mix pyrite and sulfur particles at a mass ratio of 3:7 After uniformity, add it to the oxalic acid solution, and let it soak for 5 hours; take out the mixed pyrite and sulfur obtained in the above steps and dry it to obtain filler A.

[0028] (2) Preparation of filler B: Dissolve 13g of manganese nitrate and 21g of oxalic acid in dimethylformamide (DMF) solution, transfer them to a hydrothermal reactor after they are completely dissolved, and react in the hydrothermal reactor for 6 hours. The temperature is 100°C. After the reaction, cool at room temperature, wash with DMF solution for 3 times, filter with suction and dry in a drying oven for 2 days to obtain filler B.

[0029] (3) Preparation of denitrification filler: Mix filler A and filler B uniformly at a ratio of 8:2, then add to oxalic acid solution with a conc...

Embodiment 2

[0031](1) Preparation of filler A: Prepare 30g / L p-hydroxybenzoic acid solution; uniformly grind pyrite and sulfur into fine powder with a particle size of 1-50nm, and the mass ratio of pyrite and sulfur particles is 1:1.5 After mixing evenly, add it to the p-hydroxybenzoic acid solution, and let it stand for soaking for 3 hours; take out the mixed pyrite and sulfur obtained in the above steps and dry it to obtain filler A.

[0032] (2) Preparation of packing B: mix 10gMn(ClO 4 ) 2 •6H 2 O and 30g of 3,5-imidazoledicarboxylic acid were dissolved in dimethylformamide (DMF) solution, transferred to a hydrothermal reactor after all dissolved, and reacted in the hydrothermal reactor for 16 hours at a temperature of 100°C, and the reaction was completed Afterwards, cool at room temperature, wash with DMF solution for 3 times, filter with suction and dry in a drying oven for 3 days to obtain filler B.

[0033] (3) Preparation of denitrification filler: Mix filler A and filler B u...

Embodiment 3

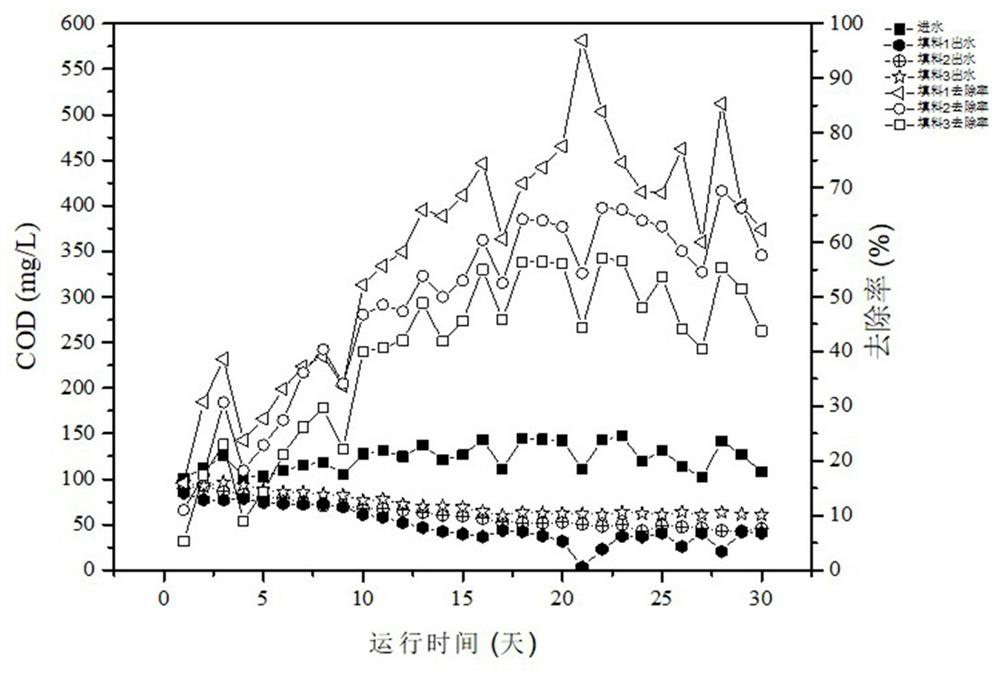

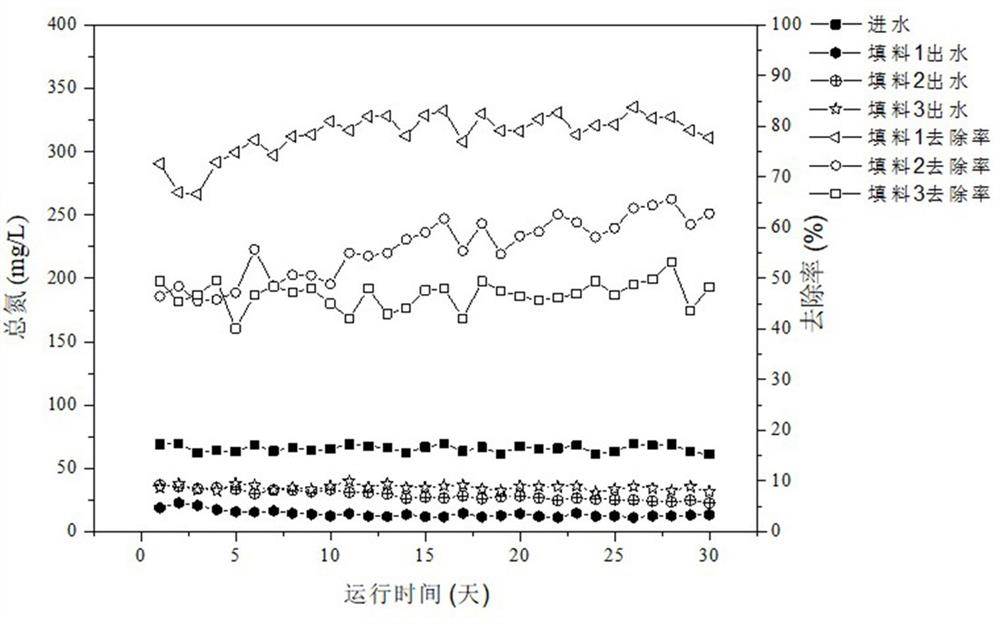

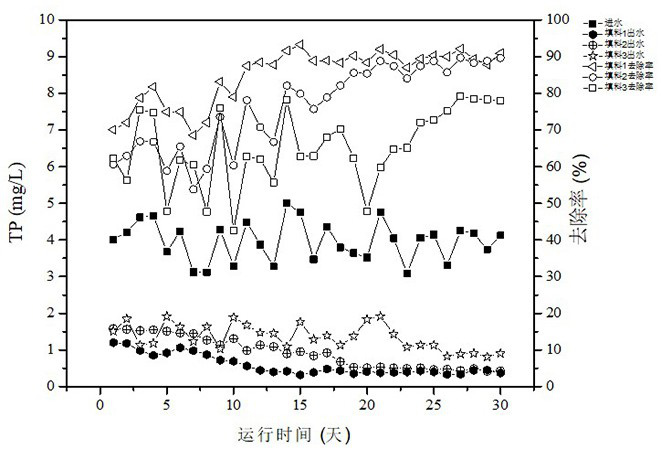

[0037] Compare the removal effects of the fillers in Examples 1 and 2 and Comparative Example 1 on COD, ammonia nitrogen, total nitrogen, and total phosphorus.

[0038] The reaction device is an aeration reactor with a volume of 15L. The filling volume of the filler is 5kg.

[0039] The test water sample is rural domestic sewage in a certain place, the influent COD is 100~150mg / L, the nitrate nitrogen is 45~60mg / L, the total nitrogen is 60~70mg / L, the total phosphorus is 3~5mg / L, and the test period is 1 In 1 month, under the condition of continuous water inflow, the removal efficiency of three kinds of fillers for pollutants was compared.

[0040] Comparing the fillers of Examples 1 and 2 with Comparative Example 1, it can be seen that the microbial film formation of the fillers of Examples 1 and 2 is formed after 12 to 15 days, and there is no need to add sulfur autotrophic bacteria in the follow-up; the water is discharged after the microbial film formation The total nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com