Colorful transmutation glaze and preparation method

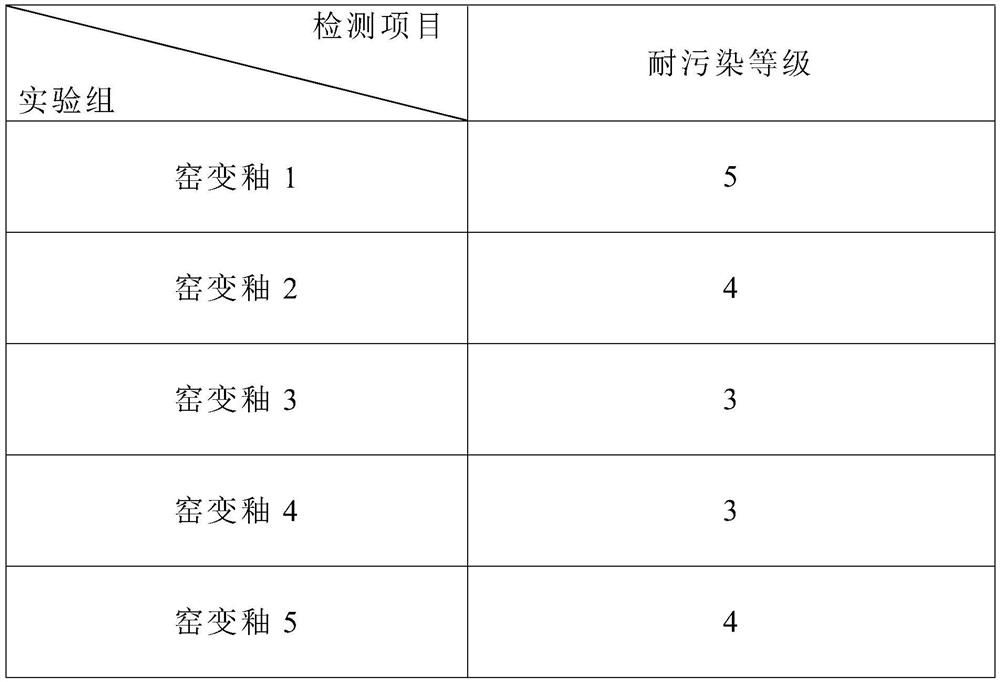

A kiln-changing glaze and colorful technology, applied in the field of kiln-changing glaze, can solve the problems of poor pollution resistance, contamination and dyeing on the surface of kiln-changing glaze, and reduced ornamental quality, and achieves the effects of low production cost, prolonged viewing time, and simple manufacturing method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a multi-color kiln-changing glaze, which includes a bottom glaze and a top glaze covering the bottom glaze.

[0027] Among them, the bottom glaze includes 20 parts by mass of calcite, 10 parts of kaolin, 8 parts of waste glass, 2 parts of iron oxide, 25 parts of potassium feldspar, 8 parts of titanium dioxide, and 20 parts of field mud. , 20 parts of frit, 5 parts of zinc oxide, 0.5 parts of copper and 50 parts of water; the surface glaze includes 15 parts of calcite, 10 parts of kaolin, 8 parts of waste glass, 18 parts of Potassium feldspar, 8 parts of titanium dioxide, 35 parts of field mud, 15 parts of frit, 8 parts of zinc oxide, 2 parts of aluminum oxide and 50 parts of water.

Embodiment 2

[0029] This embodiment provides a multi-color kiln-changing glaze, which includes a bottom glaze and a top glaze covering the bottom glaze.

[0030] Among them, the bottom glaze includes 25 parts by mass of calcite, 5 parts of kaolin, 4 parts of waste glass, 0.5 parts of iron oxide, 20 parts of potassium feldspar, 4 parts of titanium dioxide, and 10 parts of field mud. , 15 parts of frit, 3 parts of zinc oxide, 0.1 part of copper and 40 parts of water; the surface glaze includes 25 parts of calcite, 5 parts of kaolin, 4 parts of waste glass, 12 parts of Potassium feldspar, 4 parts of titanium dioxide, 25 parts of field mud, 8 parts of frit, 3 parts of zinc oxide, 0.5 parts of aluminum oxide and 40 parts of water.

Embodiment 3

[0032] This embodiment provides a multi-color kiln-changing glaze, which includes a bottom glaze and a top glaze covering the bottom glaze.

[0033] Among them, the bottom glaze includes 22 parts by mass of calcite, 7.3 parts of kaolin, 5.8 parts of waste glass, 1 part of iron oxide, 22 parts of potassium feldspar, 6 parts of titanium dioxide, and 14.5 parts of field mud. , 18 parts of frit, 3.6 parts of zinc oxide, 0.3 parts of copper and 45 parts of water; the surface glaze includes 20 parts of calcite, 9 parts of kaolin, 6 parts of waste glass, 16 parts of Potassium feldspar, 6 parts of titanium dioxide, 32 parts of field mud, 11 parts of frit, 5 parts of zinc oxide, 1 part of aluminum oxide and 45 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com