Polypropylene foam material and preparation method thereof

A technology of foaming material and polypropylene, which is applied in the field of polypropylene foaming material and its preparation, can solve problems such as limiting the application range of products and reducing impact performance, and achieve uniform foaming, maintaining impact performance and improving melt strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

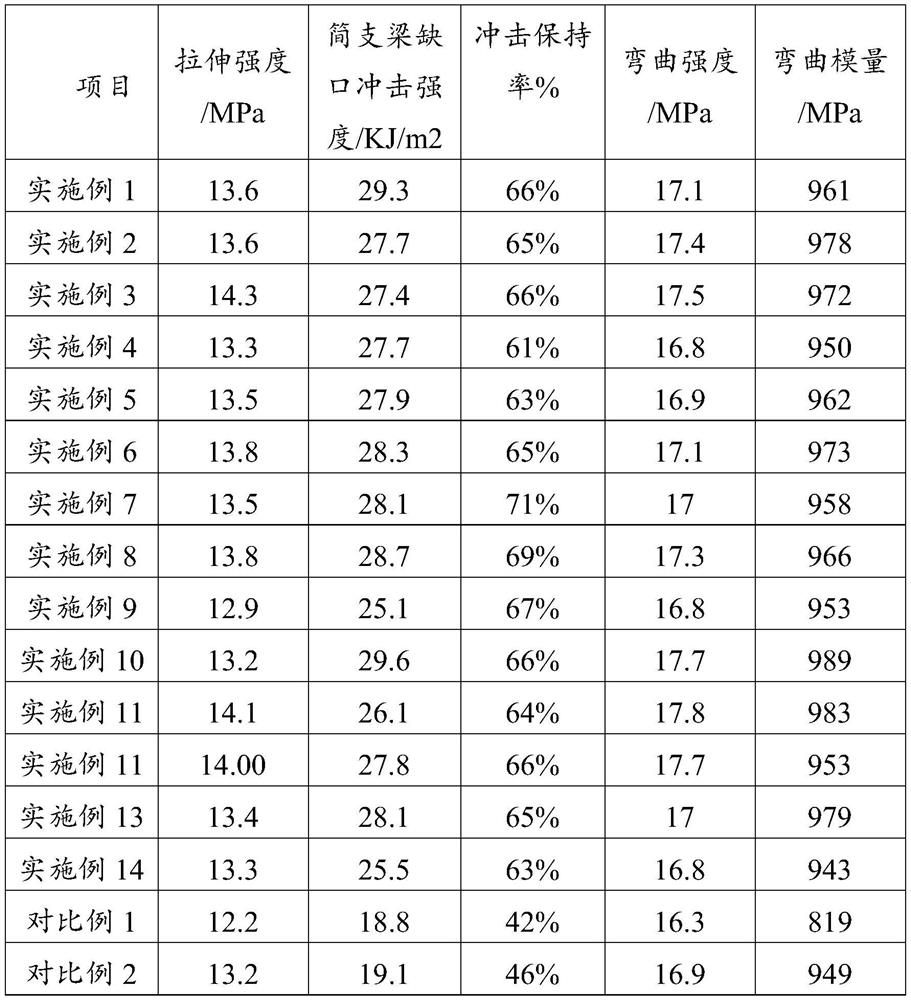

Embodiment 1

[0020]As a polypropylene foamed material according to the embodiment of the present invention, it includes 70 polypropylene resin by weight of the part: 17 parts of toughening agent; 3 parts of low density polyethylene, 10 parts of talc, compativity 0.5 parts, additives and foaming agents; compatible agents are polyolefin grafts, and polyolefin grafts are PP grafted maleic anhydrides, and toughening agents are ethylene-octene copolymers;

[0021]The toughening agent is a vinyl-octene copolymer with a density of 0.864 g / cm.3, Toughening agent at 190 ° C and 2.16 kg of melt mass flow rate is 13 g / 10 min, source: US DOW;

[0022]The auxiliary agent includes 0.2 parts of an antioxidant 1010, 0.2 parts of an antioxidant 168, 0.2 parts of light stabilizer 3808pp5 and 0.2 parts of stearate;

[0023]The polypropylene resin is a copolypropylene resin, a copolymerized polypropylene resin at 230 ° C and 2.16 kg of melt mass flow rate is 103 g / 10 min, and the source: South Korea SK;

[0024]Low densi...

Embodiment 2

[0026]As a polypropylene foam material according to the embodiment of the present invention, the only difference from the first embodiment is: 70 polypropylene resin; 14 parts of toughening agent; 6 parts of low density polyethylene, 10 tonal powder, There are 0.5 parts of compatibilizer, 3 parts of the aid and foaming agent.

Embodiment 3

[0028]As a polypropylene foam material according to the embodiment of the present invention, the only difference from the first embodiment is: 70 polypropylene resins; 11 toughening agents; 9 parts of low density polyethylene, 10 tonal powder, There are 0.5 parts of compatibilizer, 3 parts of the aid and foaming agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com