A kind of high plasticity thick gauge pipeline steel plate and its manufacturing method

A manufacturing method and pipeline steel technology, applied in the field of pipeline steel, can solve problems such as unfavorable crack arrest safety, lower low temperature impact toughness, etc., and achieve the effects of high strength, increased deformation resistance, high plasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

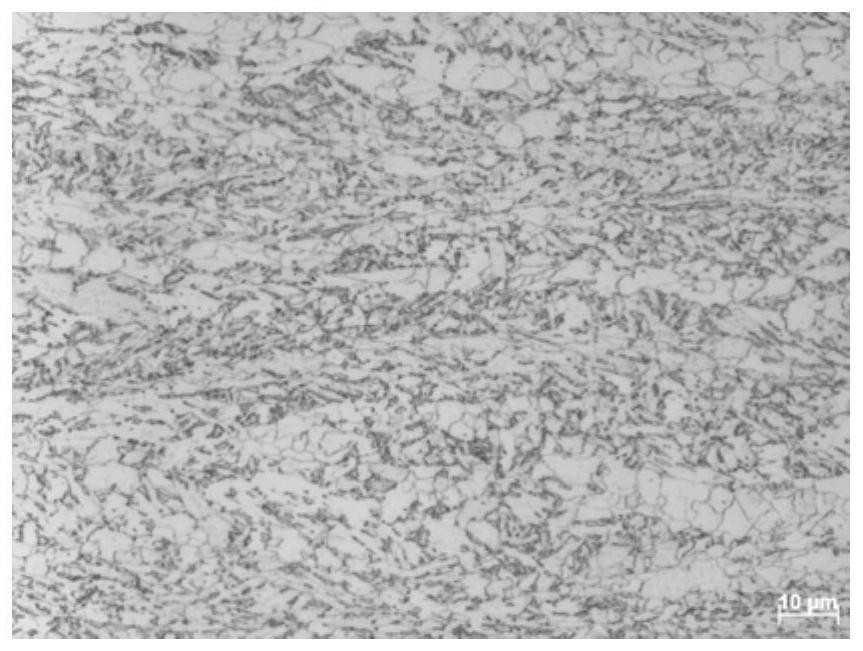

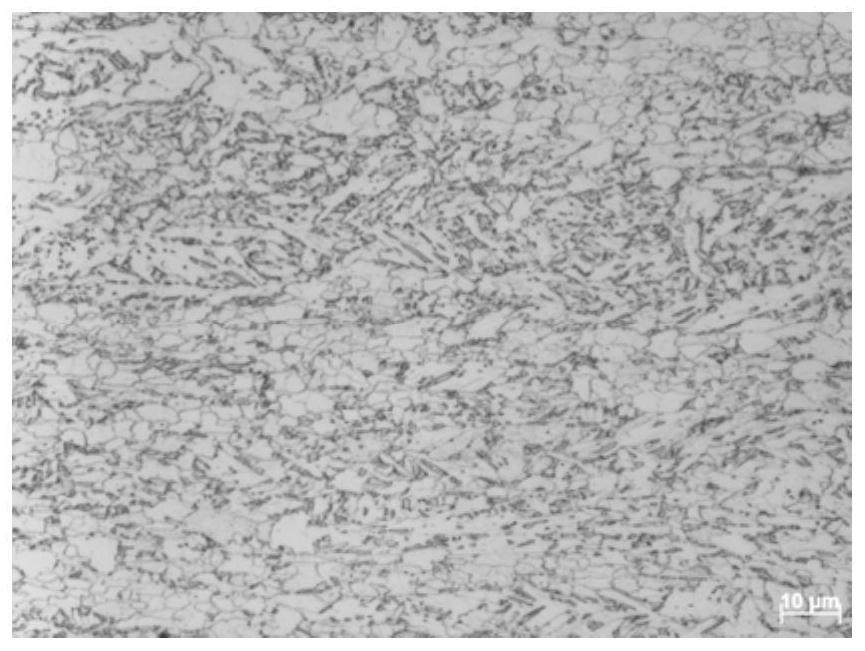

[0067] The present invention will be further described below with reference to the embodiments and accompanying drawings.

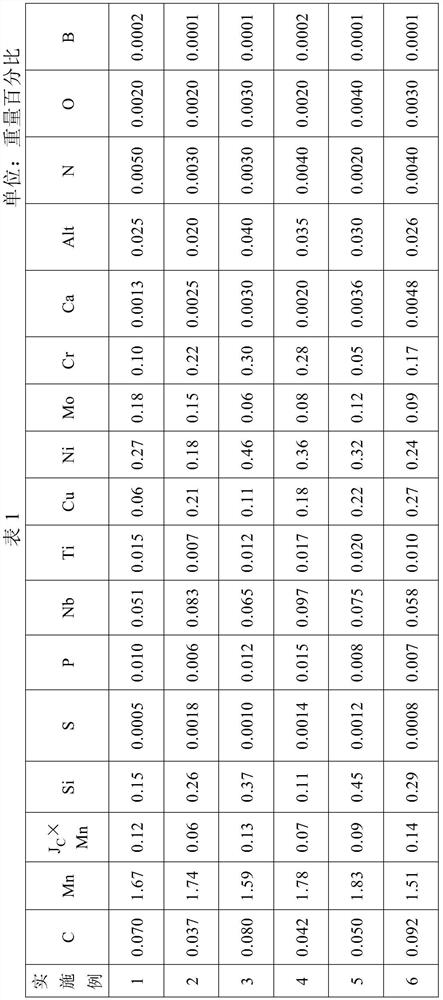

[0068] According to the steel chemical composition requirements of the present invention, the chemical compositions of the design examples are shown in Table 1, and the manufacturing process of the examples is shown in Table 2. According to the above-mentioned composition and process design, the mechanical properties obtained by each embodiment are shown in Table 3.

[0069]It can be seen that the composition and process designed according to the present invention can meet the target performance requirements, have good comprehensive mechanical properties, and have a low carbon equivalent, which is beneficial to improve the welding performance of steel pipe forming welding and on-site girth welding. In addition, the present invention has simple components, wide process window and strong manufacturability.

[0070] The high plasticity and thick specificatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com