Electrophoresis tank with accurate and controllable liquid level

An electrophoresis tank and liquid level technology, which is applied in the field of electrophoresis tanks, can solve the problems of difficulty in accurately controlling the height of the electrophoresis layer, easy changes in the liquid level, complicated deposition layers in the preparation process of the electrophoresis liquid, etc., and achieves the effect of preventing powder agglomeration and deposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

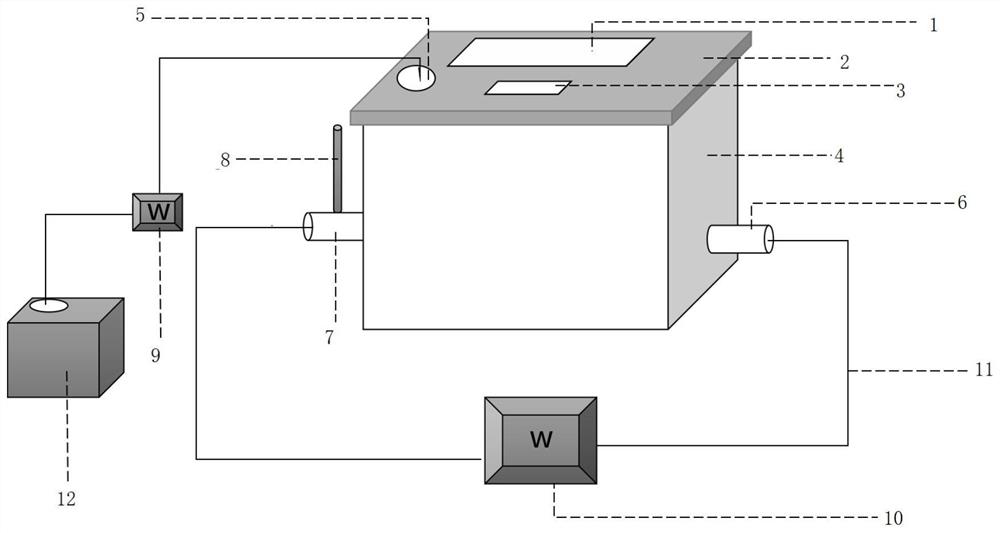

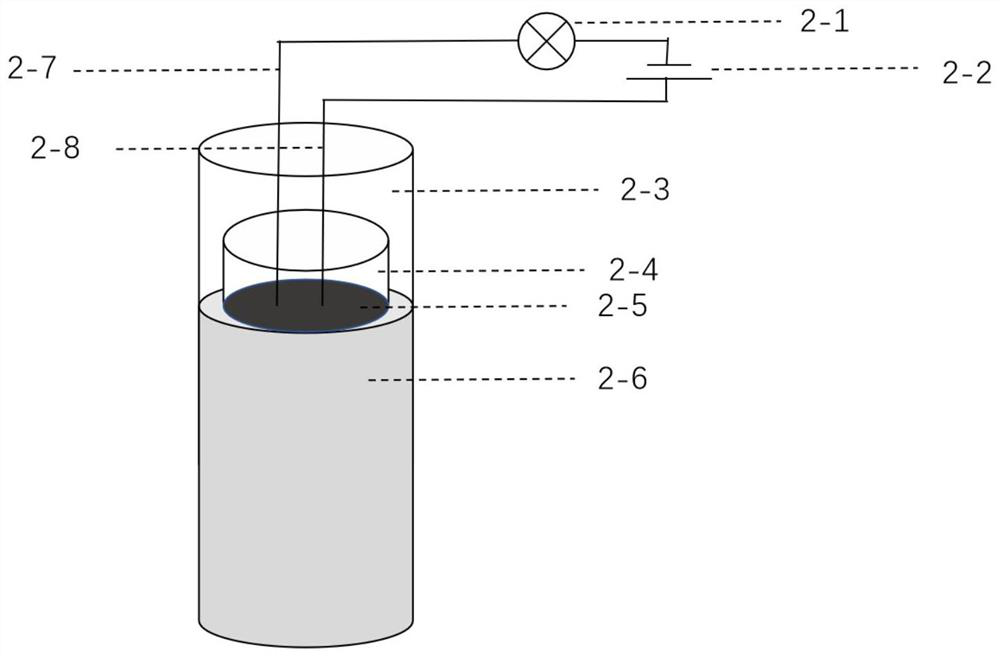

[0014] Combine below figure 1 The present invention will be specifically described. Such as figure 1 As shown, the electrophoresis tank with precise and controllable liquid level includes five parts: electrophoresis liquid tank, liquid level monitor, circulation pump, replenishment pump, and liquid storage tank. The electrophoresis tank is composed of an electrophoresis tank cover 2 and an electrophoresis tank body 4 . The electrophoresis tank cover is provided with an electrophoresis sample inlet port 1, an electrode fixing port 3, and a replenishment liquid feeding port 5. Electrophoresis fluid circulation inlet 7 and circulation outlet 6 are arranged on both sides of the electrophoresis tank. The electrophoretic fluid circulation inlet 7 communicates with the liquid level monitor 8 . The liquid level monitor is a transparent glass tube with markings inside, and the supplementary amount of electrophoretic fluid can be determined by observing the distance between the liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com