Magnesium oxide stirring device

A stirring device and magnesium oxide technology, which are applied in the directions of mixer accessories, transportation and packaging, chemical instruments and methods, etc., can solve the problems of reduced production efficiency, poor fluidity, and poor quality of brush roller coating, so as to improve production efficiency. , avoid agglomeration deposition, improve the effect of coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

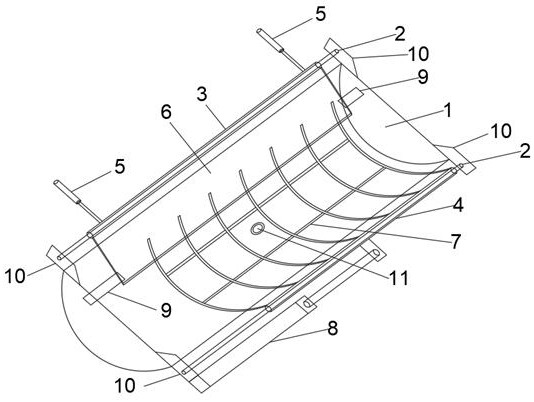

[0008] Depend on figure 1 Known, a kind of magnesia stirring device is made up of U-shaped bottom tank 1, fixed shaft 2, left side bushing 3, right side bushing 4, handle 5, scraper 6, stirring grid 7, cylinder 8, and limit block 9 composition. Each of the four corners of the U-shaped bottom groove 1 is provided with an ear 10, a limit block 9 is provided in the middle of the front and rear inner walls, and a drain hole 11 is provided at the bottom; there are two fixed shafts 2, They are respectively fixed on the ears 10 on the left and right sides of the U-shaped bottom groove 1; the left bushing 3 is set on the left fixed shaft 2, and can rotate freely on the fixed shaft 2, and several handles 5 are welded on the left side , the right side is connected with a scraper 6; the right shaft sleeve 4 is set on the right fixed shaft 2, and can slide up and down on the fixed shaft 2; The arc-shaped stainless steel bar at the bottom and the reinforcing rib connecting the stainless ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com