A carbon fiber composite material with a multi-scale high temperature resistant interface structure and its preparation method

An interface structure and composite material technology, applied in the field of carbon fiber resin matrix composite materials, can solve the problems of large damage to the performance of carbon fiber, not conforming to the development direction of green chemistry, damage to the strength of carbon fiber, etc., to improve roughness and chemical activity, realize Efficient and controllable uniform distribution, improving the effect of interface bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

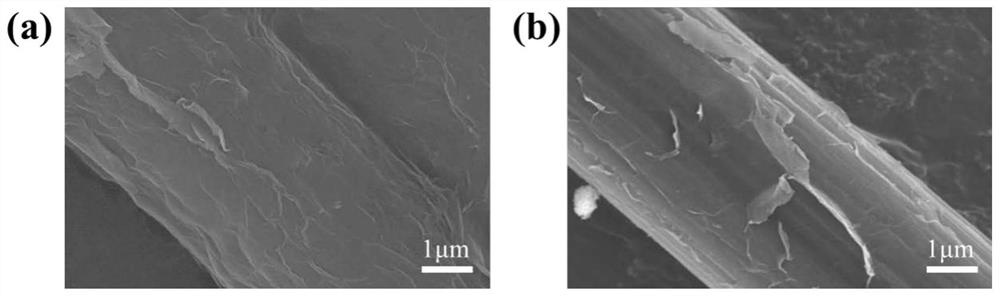

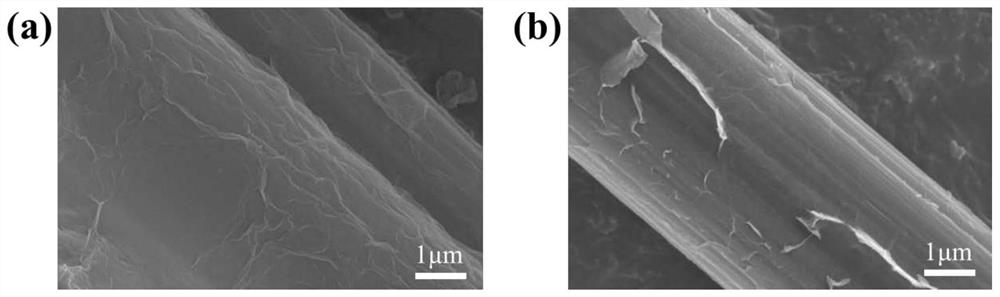

Image

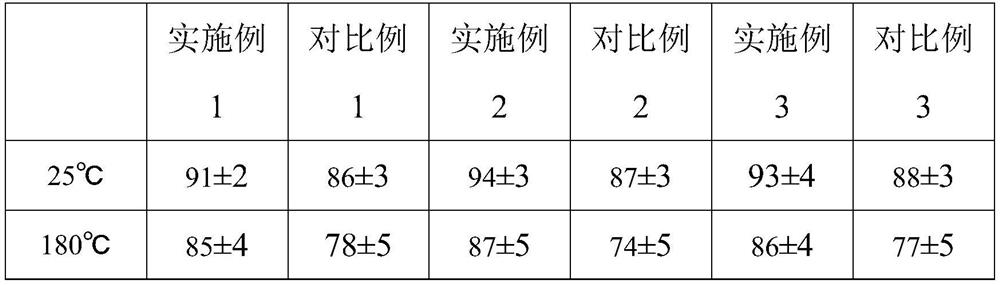

Examples

Embodiment 1

[0025] Ammonium bicarbonate aqueous solution is used for ammonium salt aqueous solution, carboxylated graphene oxide is used for nanoparticles, low molecular weight polyetherimide is used for high temperature resistant polymer, N-methylpyrrolidone is used as solvent for high temperature resistant polymer solution; The main resin is triglycidyl p-aminophenol, the curing agent of the high temperature resistant resin system is methylnadic acid anhydride, and the accelerator of the high temperature resistant resin system is 2-ethyl-4-methylimidazole (2E4MI). , Curing agent and Accelerator The ratio of mass and number of parts is 100:50:2; carbon fiber adopts Toray T800HB-12k debonded carbon fiber. Concrete preparation process is as follows:

[0026] 1) Carbon fiber surface modification:

[0027] ① Anodizing treatment: add ammonium bicarbonate to deionized water, stir and dissolve at room temperature, prepare an aqueous solution of ammonium bicarbonate with a mass concentration of...

Embodiment 2

[0036] Ammonium phosphate aqueous solution is used for the ammonium salt solution, carboxylated carbon nanotubes are used for the nanoparticles, polyamic acid is used for the high temperature resistant polymer, and N,N-dimethylformamide is used as the solvent for the high temperature resistant polymer solution; the high temperature resistant resin system The main resin is triglycidyl p-aminophenol, the curing agent of the high temperature resistant resin system is methyl tetrahydrophthalic anhydride, and the accelerator of the high temperature resistant resin system is 2-methylimidazole. The main resin, curing agent and accelerator The ratio of parts by mass is 100:80:1.5; the carbon fiber is Toray T800HB-12K degummed carbon fiber. Concrete preparation process is as follows:

[0037] 1) Carbon fiber surface modification:

[0038] ① Anodizing treatment: add ammonium phosphate to deionized water, stir and dissolve at room temperature, prepare an aqueous ammonium phosphate solut...

Embodiment 3

[0047] The ammonium salt aqueous solution uses ammonium carbonate aqueous solution, the nanoparticles use aminated graphene oxide, the high temperature resistant polymer uses aminated polyimide, and the solvent for the high temperature resistant polymer solution uses N,N-dimethylformamide; the high temperature resistant resin The main resin of the system is bismaleimide resin, the curing agent of the high temperature resistant resin system is methyl hexahydrophthalic anhydride, and the accelerator of the high temperature resistant resin system is 2-ethyl-4-methylimidazole (2E4MI) , wherein the mass ratio of the main resin, curing agent and accelerator is 100:90:0.6; the carbon fiber adopts Toray T800HB-12K glue-free carbon fiber. Concrete preparation process is as follows:

[0048] 1) Carbon fiber surface modification:

[0049] ① Anodizing treatment: add ammonium carbonate to deionized water, stir and dissolve at room temperature, prepare an aqueous solution of ammonium carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com