Working method of dredging robot

A working method and robot technology, applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problems of high cost, difficulty in collecting a single small-volume valve, and large space occupation, etc. problem, to achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

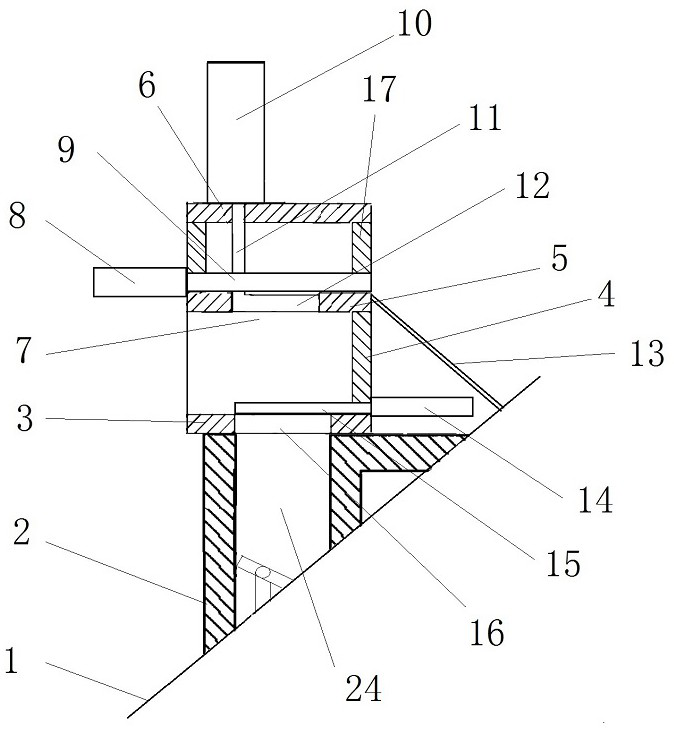

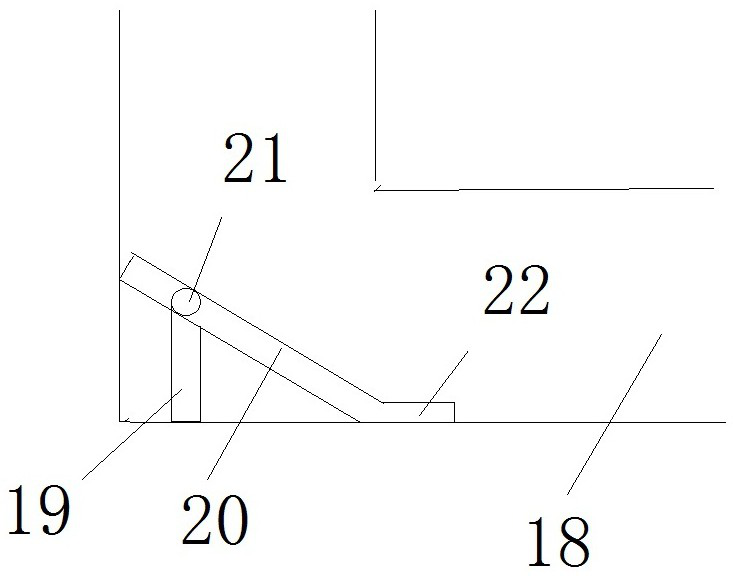

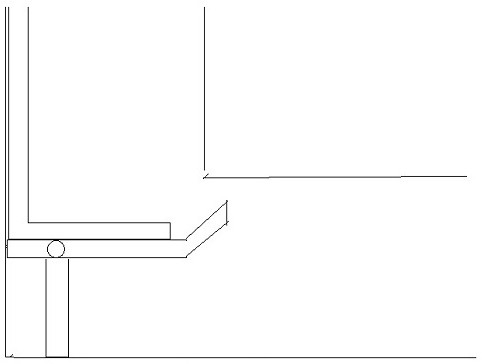

[0051]As shown in the figure: a working method of a dredging robot, the dredging robot includes a dredging equipment housing, a control unit, a monitoring module, a communication module, a power system, a sewage system, and the power system comprises a machine body. Hydraulic stations, hydraulic valves, tubes, crawler motion systems, baffles, cylinders, hydraulic stations include power motor, fuel tank, oil pump; the power motor provides power for the oil pump, the oil pump to suck the oil in the fuel tank Out of the oil pipe, the hydraulic valve controls the oil passage of the tube, the oil pipe, supplies power oil to the track motion system, and the outer side of the track moving system is provided with the baffle, machine The load is set above the track motion system.

[0052]The working methods include: real-time monitoring methods, traveling dredging methods, stacking a sludge dredging method, cleaning method.

[0053]The real-time monitoring method includes a guardrail above the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com