Semiconductor cleaning equipment

A technology for cleaning equipment and semiconductors, used in the manufacture of semiconductor/solid-state devices, cleaning methods using liquids, cleaning methods and utensils, etc. It can solve problems such as human danger, safety accidents, and environmental pollution, and reduce the probability of safety accidents. , The effect of improving the safety of use and reducing the probability of the leakage of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

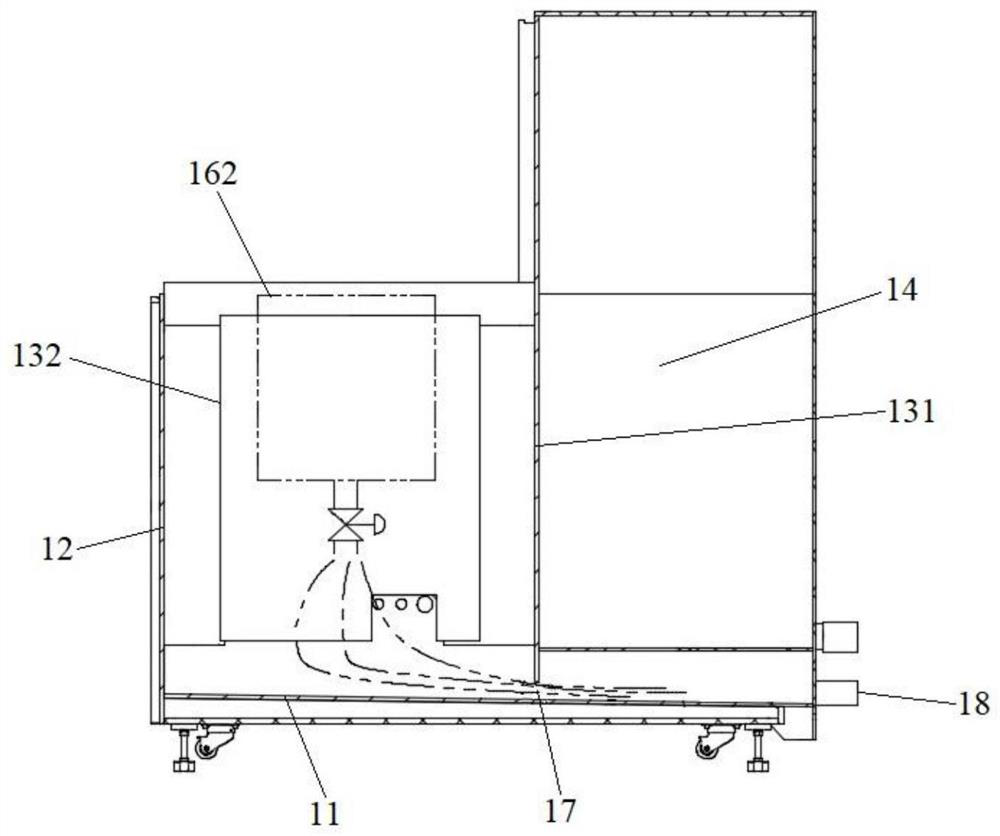

[0029] In order for those skilled in the art to better understand the technical solutions of the present invention, the semiconductor cleaning equipment provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0030] Such as Figure 3-Figure 5 As shown, this embodiment provides a semiconductor cleaning device, including a body 20 and a chemical liquid tank 21, a water tank 22, a chemical liquid discharge pipe 23, a water discharge pipe 24, a cleaning liquid distribution assembly and a liquid detection component arranged in the main body 20 25, wherein, the chemical liquid tank 21 is used to chemically clean the wafer, and the water tank 22 is used to wash the chemically cleaned wafer, and the cleaning liquid distribution assembly is communicated with the chemical liquid tank 21 and the water tank 22 respectively, and is used to supply the chemical liquid tank 21 and the water tank 22 respectively. Chemical liquid and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com