A process for preparing copper-tungsten gradient functional materials using gradient copper-tungsten alloy powder

A technology of gradient functional materials and copper-tungsten alloys, which is applied in the field of preparation of copper-tungsten gradient functional materials by using gradient copper-tungsten alloy powders, can solve the problems of not being suitable for batch production, high material costs and high processing costs, and reduce material costs and equipment Requirements, meet the mass production, the effect of easy thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

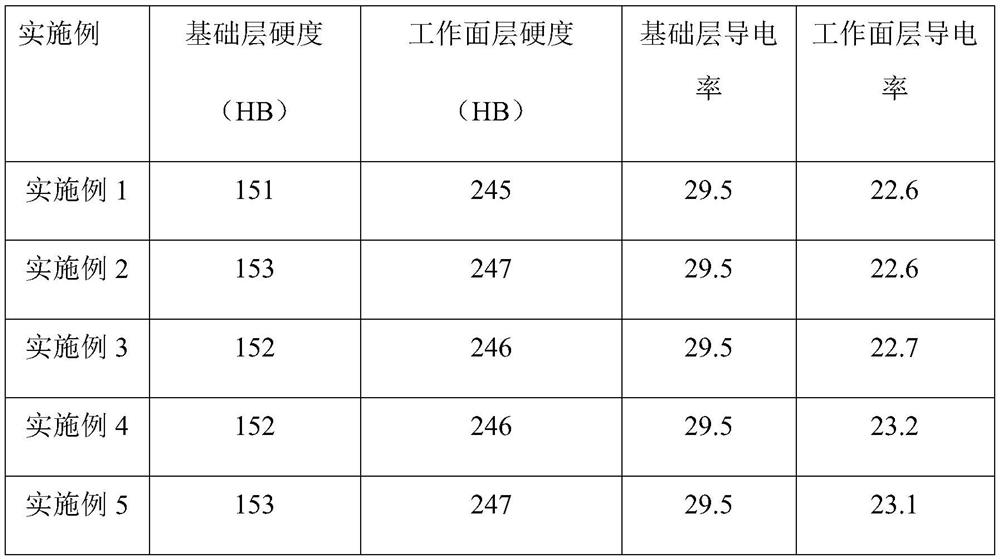

Examples

Embodiment 1

[0025] Embodiment 1: A kind of technology that utilizes gradient copper-tungsten alloy powder to prepare copper-tungsten gradient functional material, specifically includes:

[0026] Step 1: Preparation of mixed powder matrix

[0027] Put copper and tungsten powders with different gradients: CuW55 powder, CuW60 powder, CuW65 powder, CuW70 powder, CuW75 powder, CuW80 powder, CuW85 powder, CuW90 powder into the mixer in batches, and then put them into the mixer respectively. Copper tungsten powder with a mass percentage of 0.5% forming agent, mixed for 4 hours, to obtain the mixed powder matrix of copper and tungsten powder with various gradients: CuW55 powder containing 0.5% forming agent, CuW60 powder containing 0.5% forming agent, CuW65 containing 0.5% forming agent powder, CuW70 powder containing 0.5% forming agent, CuW75 powder containing 0.5% forming agent, CuW80 powder containing 0.5% forming agent, CuW85 powder containing 0.5% forming agent, CuW90 powder containing 0.5% ...

Embodiment 2

[0035] Embodiment 2: A kind of technology that utilizes gradient copper-tungsten alloy powder to prepare copper-tungsten gradient functional material, specifically includes:

[0036] Step 1: Preparation of mixed powder matrix

[0037] Put copper and tungsten powders with different gradients: CuW55 powder, CuW60 powder, CuW65 powder, CuW70 powder, CuW75 powder, CuW80 powder, CuW85 powder, CuW90 powder into the mixer in batches, and then put them into the mixer respectively. Copper tungsten powder with a mass percentage of 2% molding agent, mixed for 5 hours, to obtain the mixed powder matrix of copper and tungsten powder with various gradients: CuW55 powder with 2% molding agent, CuW60 powder with 2% molding agent, CuW65 powder with 2% molding agent , CuW70 powder containing 2% forming agent, CuW75 powder containing 2% forming agent, CuW80 powder containing 2% forming agent, CuW85 powder containing 2% forming agent, CuW90 powder containing 2% forming agent; Specifically, SBP g...

Embodiment 3

[0045] Embodiment 3: A kind of technology that utilizes gradient copper-tungsten alloy powder to prepare copper-tungsten gradient functional material, specifically includes:

[0046] Step 1: Preparation of mixed powder matrix

[0047] Put copper and tungsten powders with different gradients: CuW55 powder, CuW60 powder, CuW65 powder, CuW70 powder, CuW75 powder, CuW80 powder, CuW85 powder, CuW90 powder into the mixer in batches, and then put them into the mixer respectively. Copper tungsten powder with a mass percentage of 4% forming agent, mixed for 6 hours, to obtain the mixed powder matrix of copper and tungsten powder with various gradients: CuW55 powder containing 4% forming agent, CuW60 powder containing 4% forming agent, CuW65 containing 4% forming agent powder, CuW70 powder containing 4% forming agent, CuW75 powder containing 4% forming agent, CuW80 powder containing 4% forming agent, CuW85 powder containing 4% forming agent, CuW90 powder containing 4% forming agent; Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com