Preparation method and preparation system of ultra-high molecular weight polyethylene fiber spinning solution

An ultra-high molecular weight, polyethylene fiber technology, applied in the direction of single-component polyolefin artificial filament, spinning solution filtration, melt spinning, etc., can solve the problem of poor consistency of jelly solution, impact on final product performance, and impact on production efficiency and other problems, to achieve the effect of easy access to components, low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

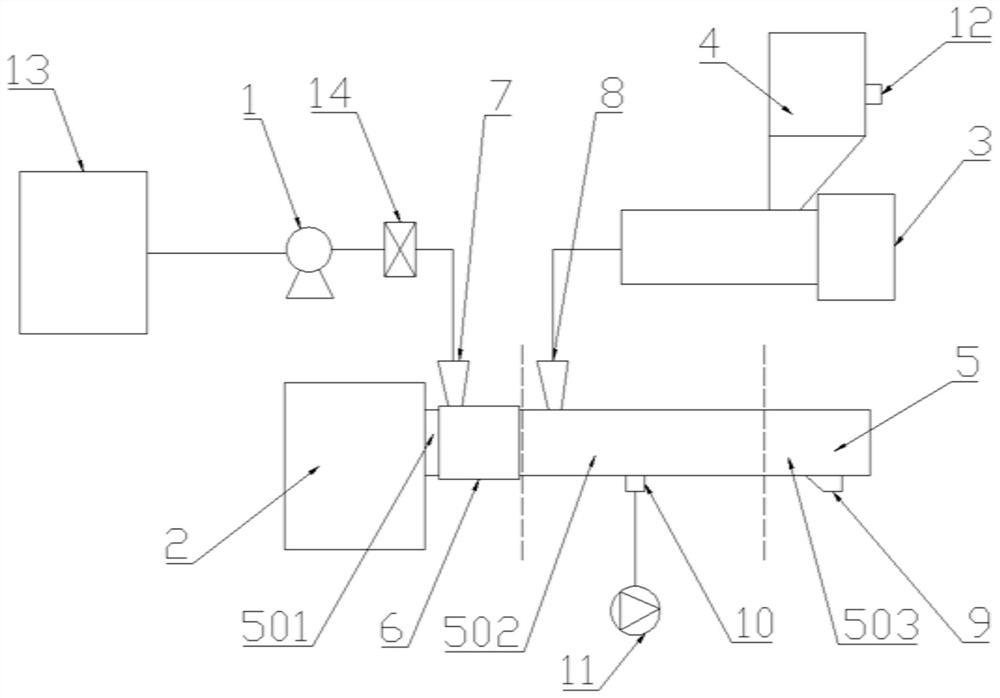

Image

Examples

Embodiment 1

[0065] A kind of ultrahigh molecular weight polyethylene fiber spinning solution, comprises ultrahigh molecular weight polyethylene powder and solvent, and the mass percentage of described ultrahigh molecular weight polyethylene powder and solvent is 1:100; Wherein, solvent is 40# white oil, super The average molecular weight of high molecular weight polyethylene powder is between 3 million and 6 million.

[0066] The preparation method and preparation system are as above.

[0067] Finished fiber strength: 42cN / dtex.

Embodiment 2

[0069] A kind of ultrahigh molecular weight polyethylene fiber spinning melt, comprises ultrahigh molecular weight polyethylene powder and solvent, and the mass percent of described ultrahigh molecular weight polyethylene powder and solvent is 50:100; Wherein, solvent is 70# white oil, super The average molecular weight of high molecular weight polyethylene powder is between 4 million and 8 million.

[0070] In the above ultra-high molecular weight polyethylene fiber spinning solution, add zinc dialkyl dithiophosphate, organic tin and polymethylurea resin, ultra-high molecular weight polyethylene powder and zinc dialkyl dithiophosphate, organic tin The weight ratio to polymethylurea resin is: 1:0.03:0.2:0.17.

[0071] The preparation method and preparation system are as above.

[0072] Finished fiber strength: 41cN / dtex.

Embodiment 3

[0074] A kind of ultrahigh molecular weight polyethylene fiber spinning solution, comprises ultrahigh molecular weight polyethylene powder and solvent, and the mass percentage of described ultrahigh molecular weight polyethylene powder and solvent is 1:100; Wherein, solvent is 40# white oil, super The average molecular weight of high molecular weight polyethylene powder is between 3 million and 6 million.

[0075] In the above ultra-high molecular weight polyethylene fiber spinning solution, add zinc dialkyl dithiophosphate, organic tin, aluminum hydroxide and polymethylurea resin, ultra-high molecular weight polyethylene powder and dialkyl dithiophosphoric acid The weight ratio of zinc, organotin, aluminum hydroxide and polymethylurea resin is: 1:0.04:0.25:0.10:0.08.

[0076] The preparation method and preparation system are as above.

[0077] Finished fiber strength: 45cN / dtex.

[0078] Carry out usual experiments, comparative experiments, and blank experiments, and will n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com